F-shaped steel for high magnetic flux density maglev track and production method thereof

A technology of high magnetic flux density and magnetic levitation track, applied in the field of metallurgy, can solve the problems of complex composition, low magnetic flux density and high production cost, achieve the effects of simple production process control, increase magnetic flux density and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

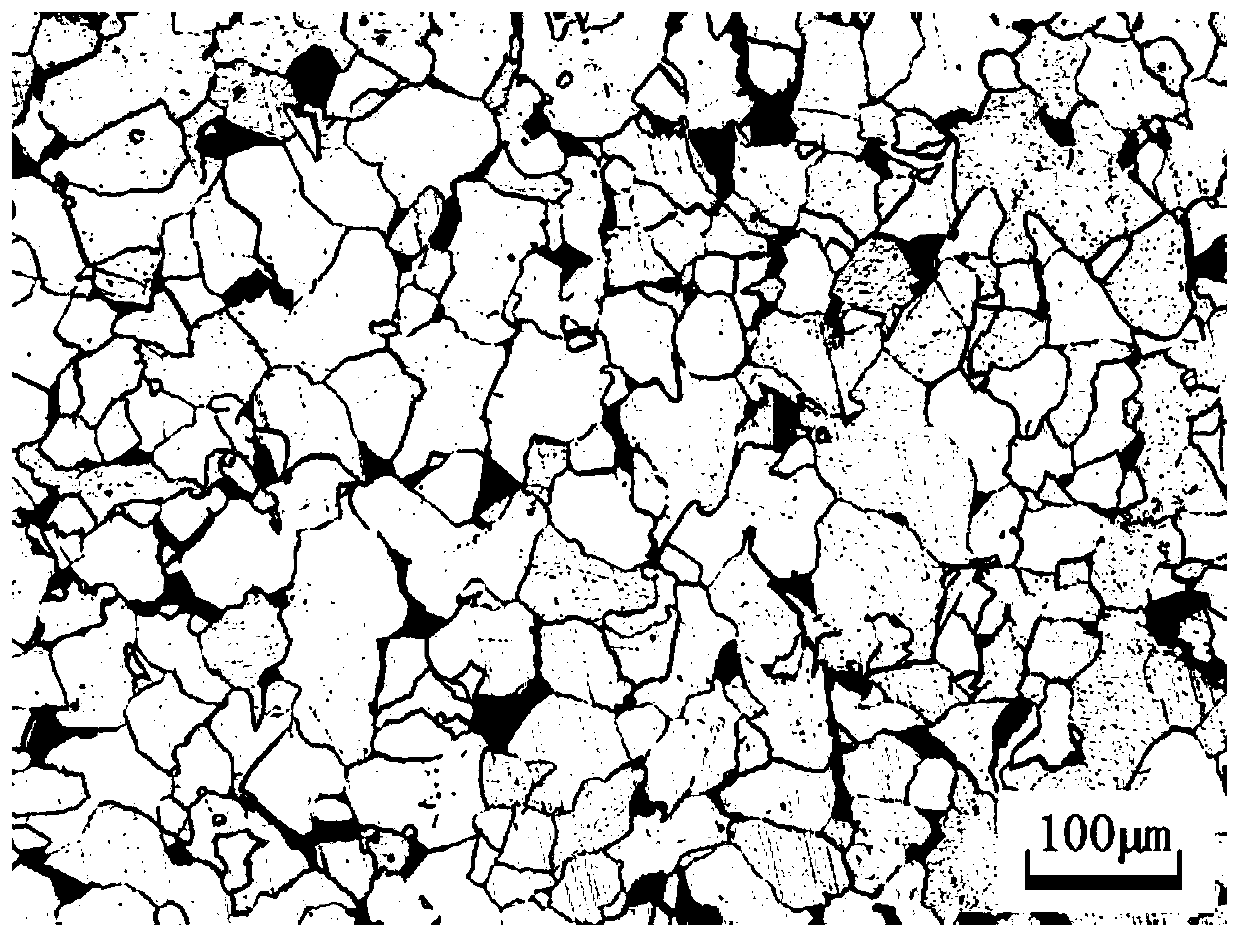

Image

Examples

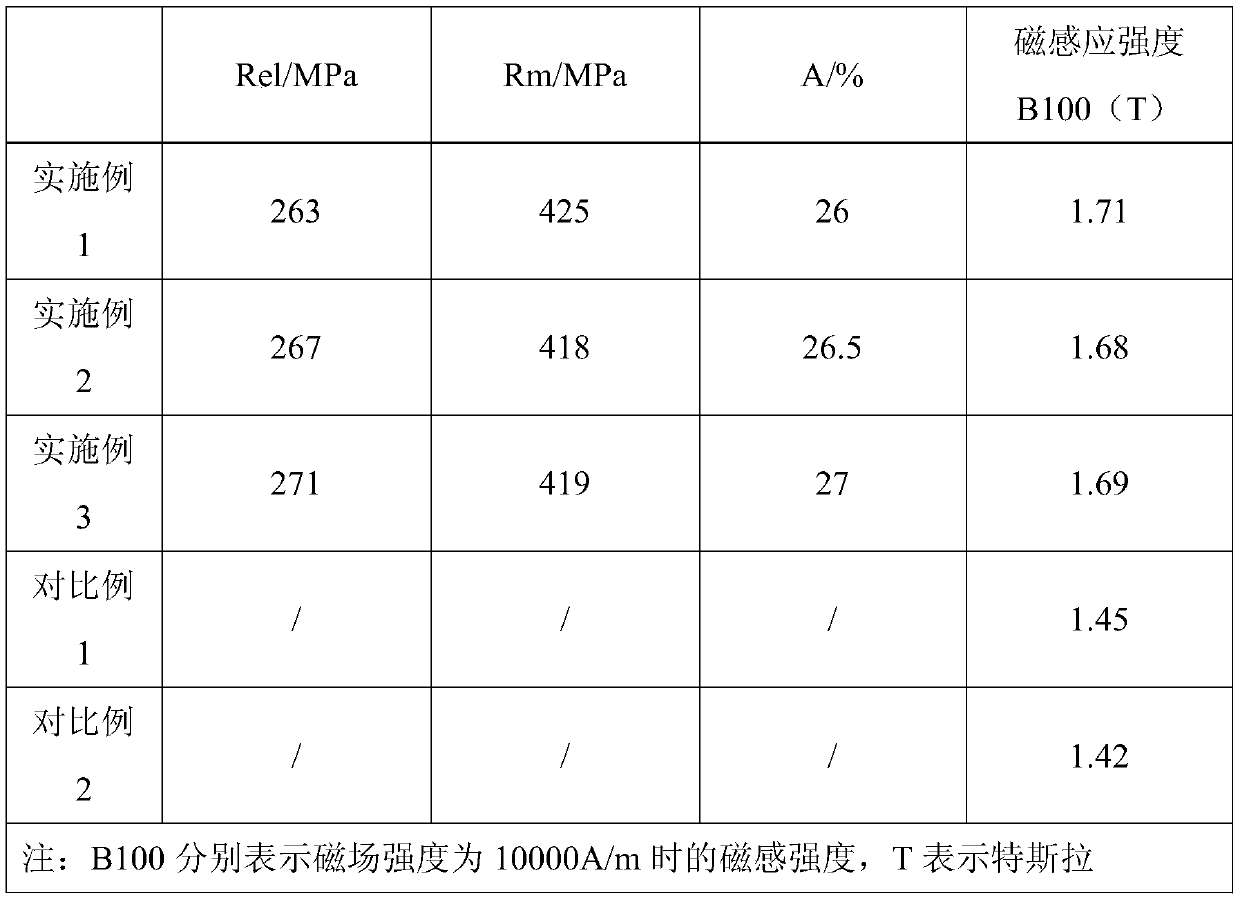

Embodiment 1

[0023] An F-shaped steel for high magnetic flux density maglev track, the chemical composition is: C: 0.045%, Si: 0.11%, Mn: 0.58%, P: 0.007%, S: 0.005%, Nb: 0.027%, Als : 0.0376%, the rest is Fe and impurity elements. Its production process is as follows:

[0024] 1) Desulfurization of molten iron and converter smelting are carried out routinely, and the tapping temperature is controlled at 1667°C;

[0025] 2) Add active lime, etc. to make white slag, the slag basicity is controlled at 1.93, and the treatment time of LF furnace is 42 minutes;

[0026] 3) RH vacuum treatment: using deep vacuum, the treatment time is 12min at a pressure of 59Pa;

[0027] 4) For continuous casting, the long nozzle of the large tank and the submerged nozzle of the crystallizer are used to protect the pouring, and the immersion depth is 79mm; the temperature of the molten steel in the tundish is controlled at 13°C above the liquidus temperature line of the steel; the casting speed is controlled ...

Embodiment 2

[0034] An F-shaped steel for high magnetic flux density maglev track, the chemical composition is: C: 0.047%, Si: 0.095%, Mn: 0.62%, P: 0.008%, S: 0.003%, Nb: 0.026%, Als : 0.0412%, the rest is Fe and impurity elements. Its production process is as follows:

[0035] 1) Conduct molten iron desulfurization and converter smelting routinely, and control the tapping temperature at 1671°C;

[0036] 2) Add active lime, etc. to make white slag, the slag basicity is controlled at 1.85, and the treatment time of LF furnace is 37 minutes;

[0037] 3) RH vacuum treatment: using deep vacuum degree, the treatment time is 13min at a pressure of 63Pa;

[0038] 4) For continuous casting, the long nozzle of the large tank and the submerged nozzle of the crystallizer are used to protect the pouring, and the immersion depth is 81mm; the temperature of the molten steel in the tundish is controlled at 18°C above the liquidus temperature line of the steel; the casting speed is controlled at 0.6...

Embodiment 3

[0045] An F-shaped steel for high magnetic flux density maglev track, the chemical composition is: C: 0.057%, Si: 0.105%, Mn: 0.57%, P: 0.005%, S≤0.005%, Nb: 0.028%, Als : 0.0427%, the rest is Fe and impurity elements. Its production process is as follows:

[0046] 1) Desulfurization of molten iron and converter smelting are carried out routinely, and the tapping temperature is controlled at 1655°C;

[0047] 2) Add active lime, etc. to make white slag, the slag alkalinity is controlled at 1.97, and the treatment time of LF furnace is 57 minutes;

[0048] 3) RH vacuum treatment: using deep vacuum degree, the treatment time is 15min at a pressure of 61Pa;

[0049] 4) For continuous casting, the long nozzle of the large tank and the submerged nozzle of the crystallizer are used to protect the pouring, and the immersion depth is 77mm; the temperature of the molten steel in the tundish is controlled at 13°C above the liquidus temperature line of the steel type; the casting speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com