A high-strength hot-rolled steel strip with reduced manganese and improved band structure and its manufacturing method

A technology with banded structure and high strength, which is applied in the fields of metal material manufacturing, iron and steel smelting, and controlled rolling and controlled cooling. It can solve the problems of limited improvement of banded structure, achieve easy production process control, improve cold forming performance, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

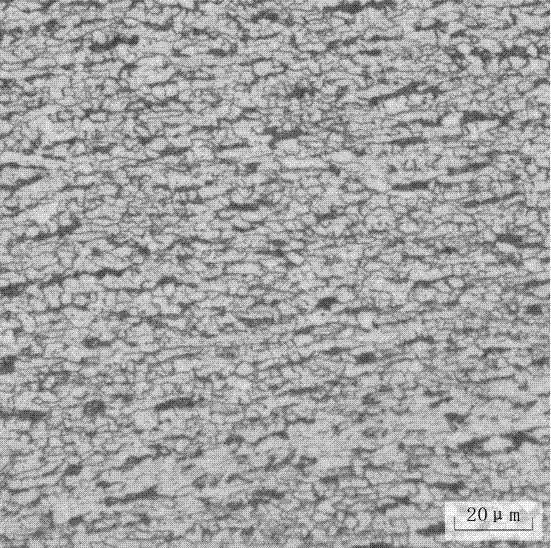

Embodiment 1

[0025] The specific composition of the slab in this embodiment is by weight percentage: C: 0.14%, Si: 0.15%, Mn: 0.60%, P: 0.015%, S: 0.010%, Ti: 0.06%, Alt: 0.027%, and the rest are Fe and unavoidable impurities, continuous casting slab thickness 230mm.

[0026] The specific production process is carried out according to the following steps:

[0027] 1) Billet heating: heat the billet to 1240-1280°C (the specific temperature is controlled by the computer according to the thickness of the billet and the production rhythm), keep warm for 190 minutes, fully austenitize, and ensure the re-dissolution of micro-alloy elements;

[0028] 2) Rolling in the recrystallization zone: the rolling start temperature in the recrystallization zone is 1180°C, and the final rolling temperature in the recrystallization zone is controlled at 1040°C to obtain an intermediate billet. The reduction rate of each pass in the recrystallization zone is controlled at 25%~40%;

[0029] 3) Rolling in the ...

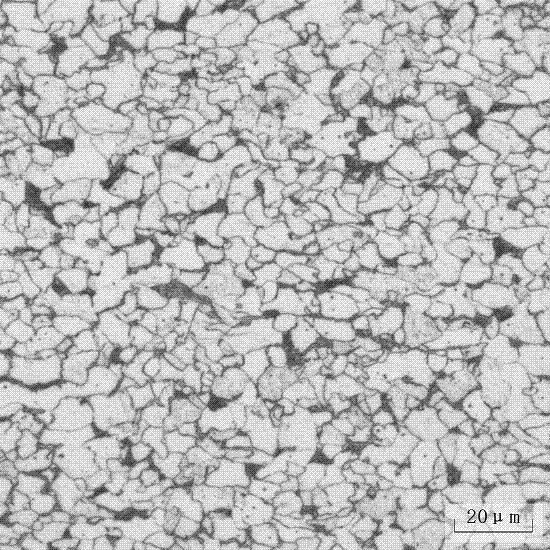

Embodiment 2

[0036] The specific composition of the cast slab in this embodiment is: C: 0.17%, Si: 0.35%, Mn: 0.55%, P: 0.020%, S: 0.003%, Ti: 0.05%, Alt: 0.020%, and the rest are Fe and unavoidable impurities, continuous casting slab thickness 230mm.

[0037] The specific production process is carried out according to the following steps:

[0038] 1) Billet heating: heat the billet to 1240-1280°C, keep it warm for 180min, and austenitize the components;

[0039] 2) Rolling in the recrystallization zone: the rolling start temperature in the recrystallization zone is 1160°C, and the final rolling temperature in the recrystallization zone is controlled at 1020°C to obtain an intermediate billet. The reduction rate of each pass in the recrystallization zone is controlled at 25%~40%;

[0040] 3) Rolling in the non-recrystallized area: when the intermediate billet is cooled to 930°C, the rolling in the non-recrystallized area is carried out, the final rolling temperature is 850°C, and the cum...

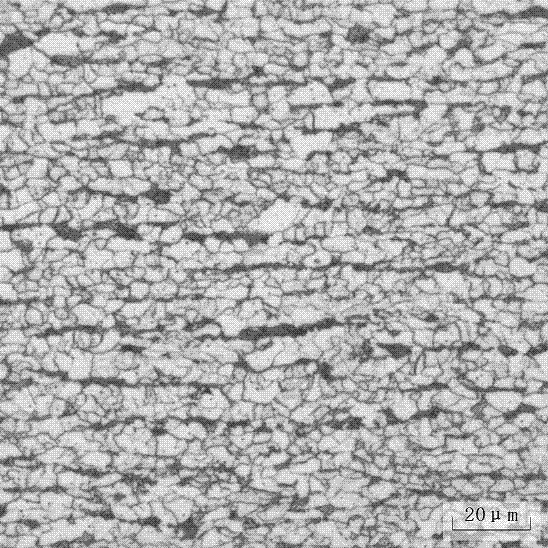

Embodiment 3

[0047] The specific composition of the cast slab in this embodiment is: C: 0.15%, Si: 0.25%, Mn: 0.40%, P: 0.014%, S: 0.004%, Ti: 0.040%, Alt: 0.040%, and the rest are Fe and unavoidable impurities, continuous casting slab thickness 230mm.

[0048] The specific production process is carried out according to the following steps:

[0049] 1) Billet heating: heat the billet to 1240-1280°C, keep it warm for 200min, and austenitize the components;

[0050] 2) Rolling in the recrystallization zone: the rolling start temperature in the recrystallization zone is 1190°C, and the final rolling temperature in the recrystallization zone is controlled at 1050°C to obtain an intermediate billet. The reduction rate of each pass in the recrystallization zone is controlled at 25%~40%;

[0051] 3) Rolling in the non-recrystallized area: when the intermediate billet is cooled to 940°C, the rolling in the non-recrystallized area is carried out, the final rolling temperature is 830°C, and the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com