Hot-rolled strip steel for automobile structure and manufacturing method

A technology for automobile structure and hot-rolled strip, applied in the field of metallurgy, can solve problems such as easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

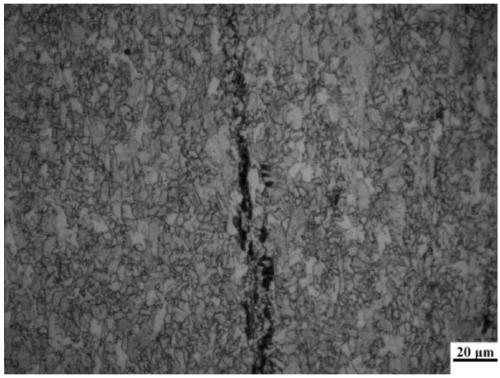

[0028] The embodiment of the present invention provides a kind of hot-rolled steel strip for automobile structure, please refer to figure 1 , the composition mass percentage of the steel strip is C: 0.030-0.080wt%, Si: 0.15-0.25wt%, Mn: 1.00-1.60wt%, P: ≤0.020wt%, S: ≤0.005wt%, Al: 0.02-0.05wt%, Nb: 0.020-0.060wt%, Ti: 0.01-0.03wt%, V: 0.02-0.06wt%, Cr: 0.10-0.30wt%, and the rest are Fe and unavoidable impurities.

[0029] Further, the mass percentage of a part of the steel strip is C: 0.35-0.07wt%, Mn: 1.0-1.5%wt%, Nb: 0.03-0.45wt%, Ti: 0.01-0.025wt%, V: 0.025wt% 0.04wt%, Cr: 0.15-0.25wt%.

[0030] Further, the mass percentage of a part of the steel strip is C: 0.04-0.07wt%, Mn: 1.1-1.5%wt%, Nb: 0.03-0.05wt%, Ti: 0.015-0.025wt%, V: 0.025wt% 0.045wt%, Cr: 0.15-0.25wt%.

[0031] Further, the mass percentage of a part of the steel strip is C: 0.03-0.07wt%, Mn: 1.0-1.4%wt%, Nb: 0.03-0.04wt%, Ti: 0.01-0.02wt%, V: 0.02-0.02wt%. 0.04wt%, Cr: 0.15-0.2wt%.

[0032] Specifically, ...

Embodiment 2

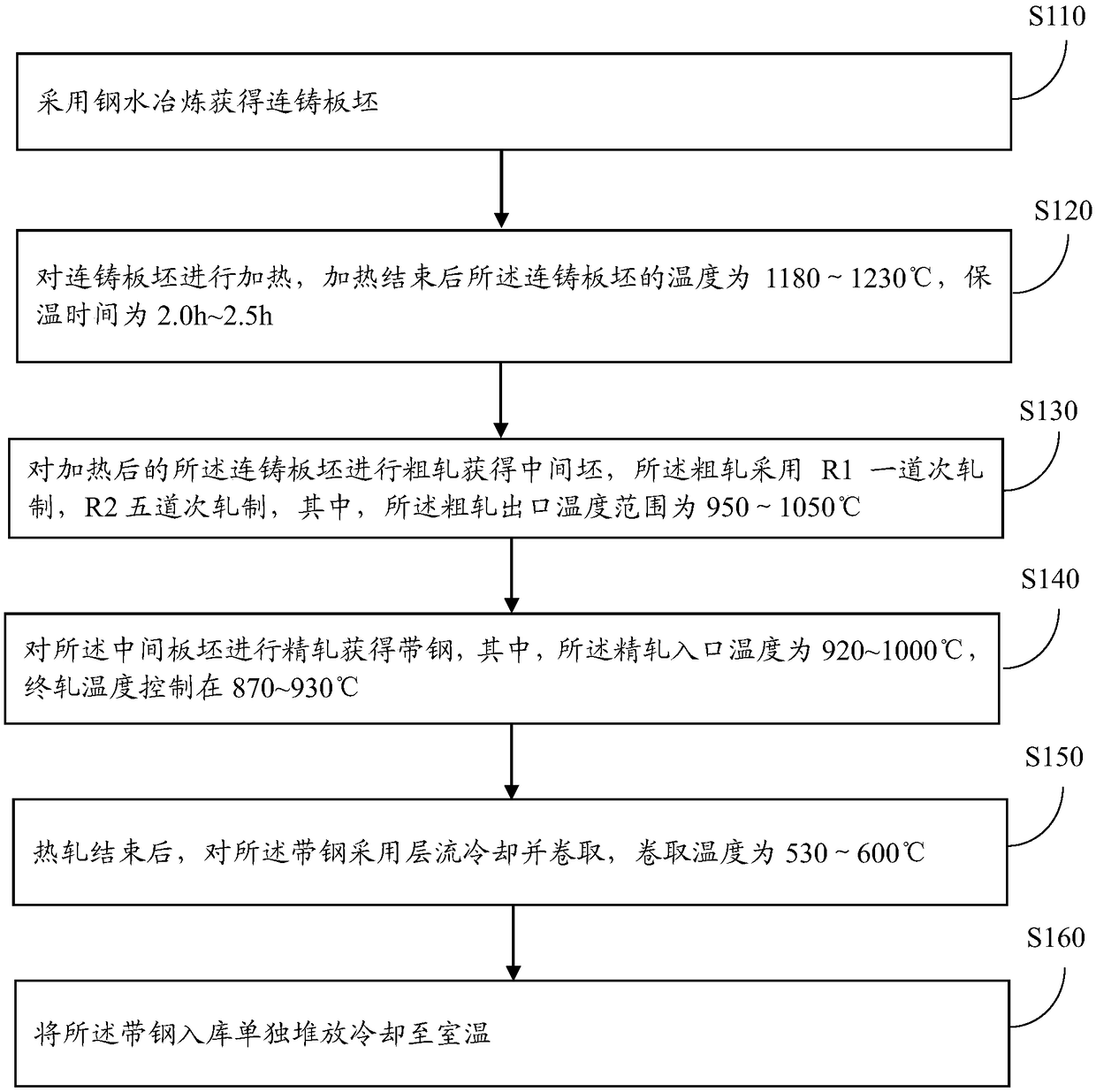

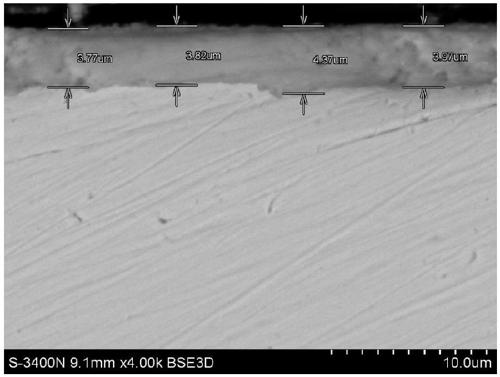

[0040] This embodiment provides a kind of manufacturing method of hot-rolled steel strip for automobile structure, please refer to Figure 2 to Figure 5 , the method includes:

[0041] Step 110: Continuous casting slabs are obtained by smelting molten steel; the composition mass percentages of the continuous casting slabs are C: 0.030-0.080 wt%, Si: 0.15-0.25 wt%, Mn: 1.00-1.60 wt%, P: ≤0.020wt%, S: ≤0.005wt%, Al: 0.02~0.05wt%, Nb: 0.020~0.060wt%, Ti: 0.01~0.03wt%, V: 0.02~0.06wt%, Cr: 0.10~0.30wt% %, the rest is Fe and unavoidable impurities.

[0042] Specifically, in the examples of the present application, the mass percentages of the component ranges smelted by smelting methods such as converters are C: 0.030-0.080wt%, Si: 0.15-0.25wt%, Mn: 1.00-1.60wt%, P: ≤ 0.020wt%, S: ≤0.005wt%, Al: 0.02~0.05wt%, Nb: 0.020~0.060wt%, Ti: 0.01~0.03wt%, V: 0.02~0.06wt%, Cr: 0.10~0.30wt% , and the rest are Fe and unavoidable impurities. The molten steel was smelted according to the set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com