Method for producing high elastic fiber by using PET (polyethylene terephthalate) polyester, and high elastic fiber obtained by same

A technology of elastic fiber and primary fiber, which is applied in the field of high elastic fiber and high elastic fiber based on conventional PET, can solve the problems of high product price, high static electricity, high production cost, etc., and achieve the improvement of orientation degree and arrangement regularity, production process Controlling simple, rigidity-increased effects

Active Publication Date: 2013-12-18

SUZHOU LONGJIE SPECIAL FIBER

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Invention Patent Publication No. CN1379129A discloses stable elastic fiber, which obtains elastic fiber by PU block, and its disadvantage is that the production cost is high and the product price is expensive

[0005] The invention patent application number is 200910262863.5, which discloses a production method of PBT high elastic yarn, which is obtained by texturizing PBT material through spinning. The disadvantage of this method is that the product cost is high, and the produced product has high static electricity. Antistatic treatment, not comfortable enough to wear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~5

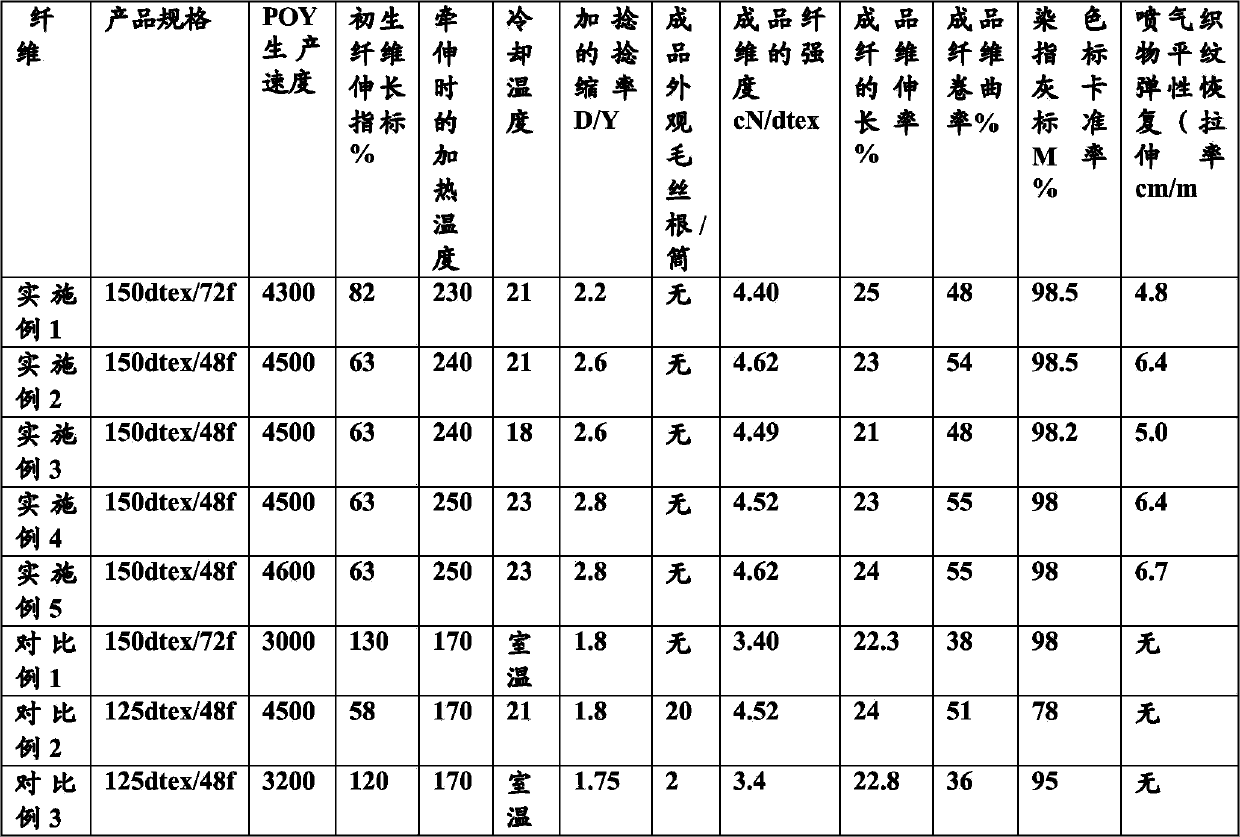

[0029] Examples 1 to 5 are specific examples of producing high-elastic fibers according to the method of the present invention, and the key process parameters adopted by them and the obtained key technical indicators for producing high-elastic fibers are listed in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

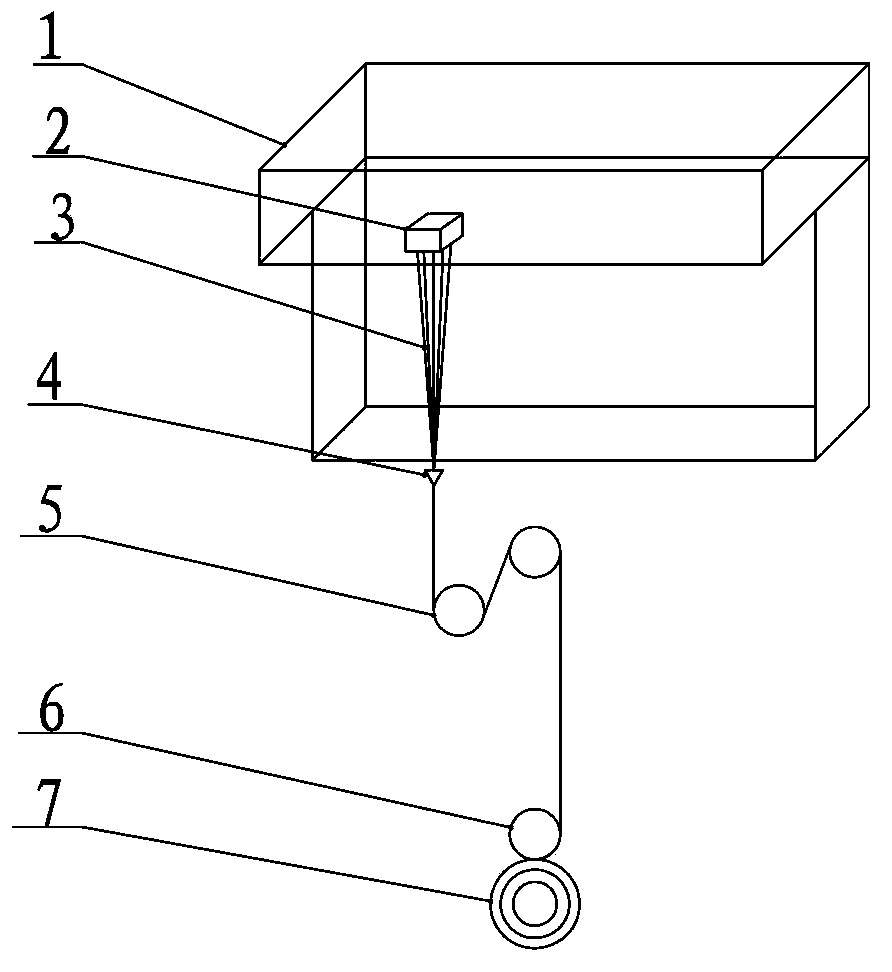

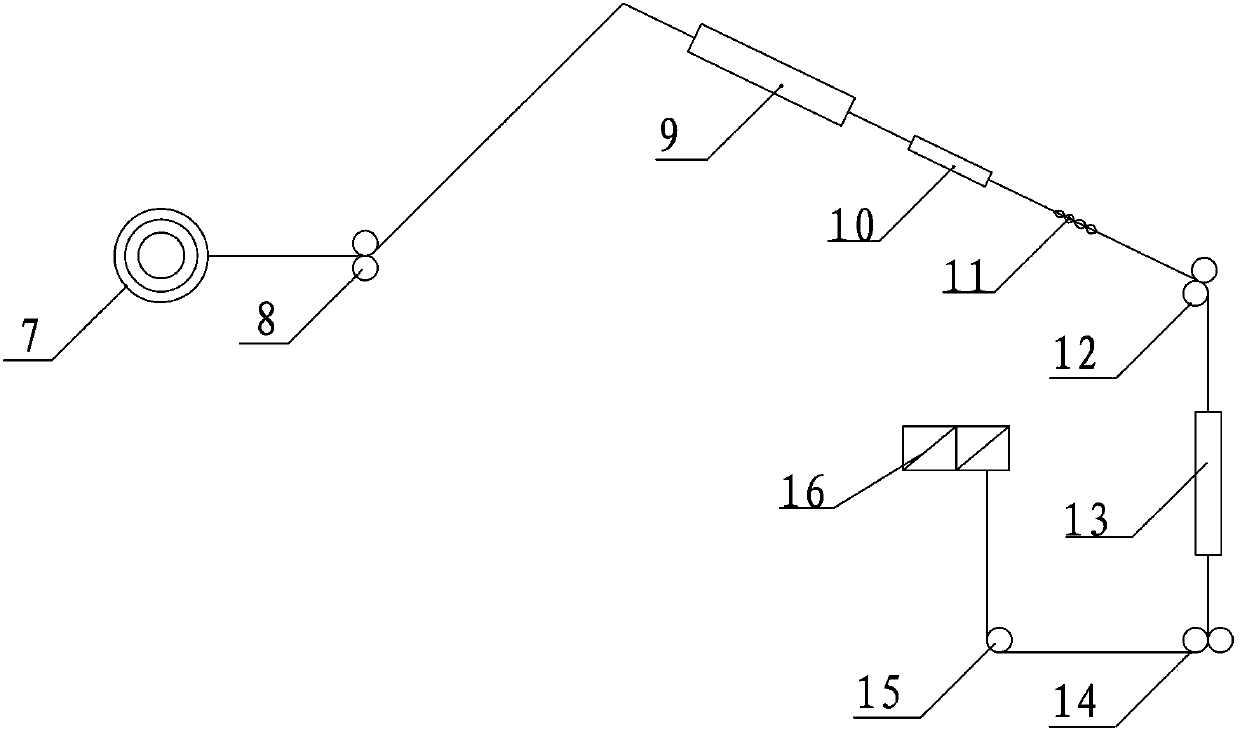

The invention relates to a method for producing a high elastic fiber by using PET (polyethylene terephthalate) polyester, which comprises the following steps that: (1) a PET polyester melt sequentially enters a spinning box, a metering pump and a spinning assembly to obtain a protofiber, and the protofiber is sequentially cooled, oiled and wound to obtain a POY (Pre Oriented Yarn), wherein the production speed of the POY is controlled between 4300m / min and 4600m / min; and (2) the POY sequentially passes through a first roller, a heating source, a cooling plate, a twisting device and a second roller for drafting and twisting, the tension is stabilized by a molding roller, and the POY is lubricated by an oiling roller and is wound to obtain the high elastic fiber, wherein the heating temperature of the heating source is between 230 DEG C and 250 DEG C, the twist shrinkage rate of twisting is between 2.2 and 2.8, and the cooling temperature of the cooling plate is between 18 DEG C and 23 DEG C. The process provided by the invention has simple control and lower cost.

Description

technical field [0001] The invention relates to a method for preparing elastic fibers, in particular to a method for producing high elastic fibers based on conventional PET. The invention also relates to high elastic fibers prepared by this method. Background technique [0002] With the improvement of people's living standards, the individual requirements for clothing are becoming stronger and stronger, and products that can reflect beauty and are comfortable to wear are more and more popular among people who love life. [0003] At present, the methods of producing elastic fibers include using PBT, PET and PU, and using two or more materials to make the fibers elastic through composite spinning, and also using PET for elastic treatment to make the fibers have certain elasticity. Using PBT, PET, PU and other materials to realize the elasticity of fibers is expensive because of its raw materials, complex processing technology, and high production costs, resulting in high pric...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D01D5/08D02G1/02D02J13/00D01F6/62

Inventor 赵满才席文杰陆建忠

Owner SUZHOU LONGJIE SPECIAL FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com