Super-thick steel plate with obdurability matching and excellent high-temperature performance and manufacturing method thereof

A high-temperature performance, extra-thick steel plate technology, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of welding environment deterioration, temper embrittlement, heat-affected zone HAZ toughness, etc., to achieve fatigue resistance and creep Excellent variable performance, excellent strength and toughness matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

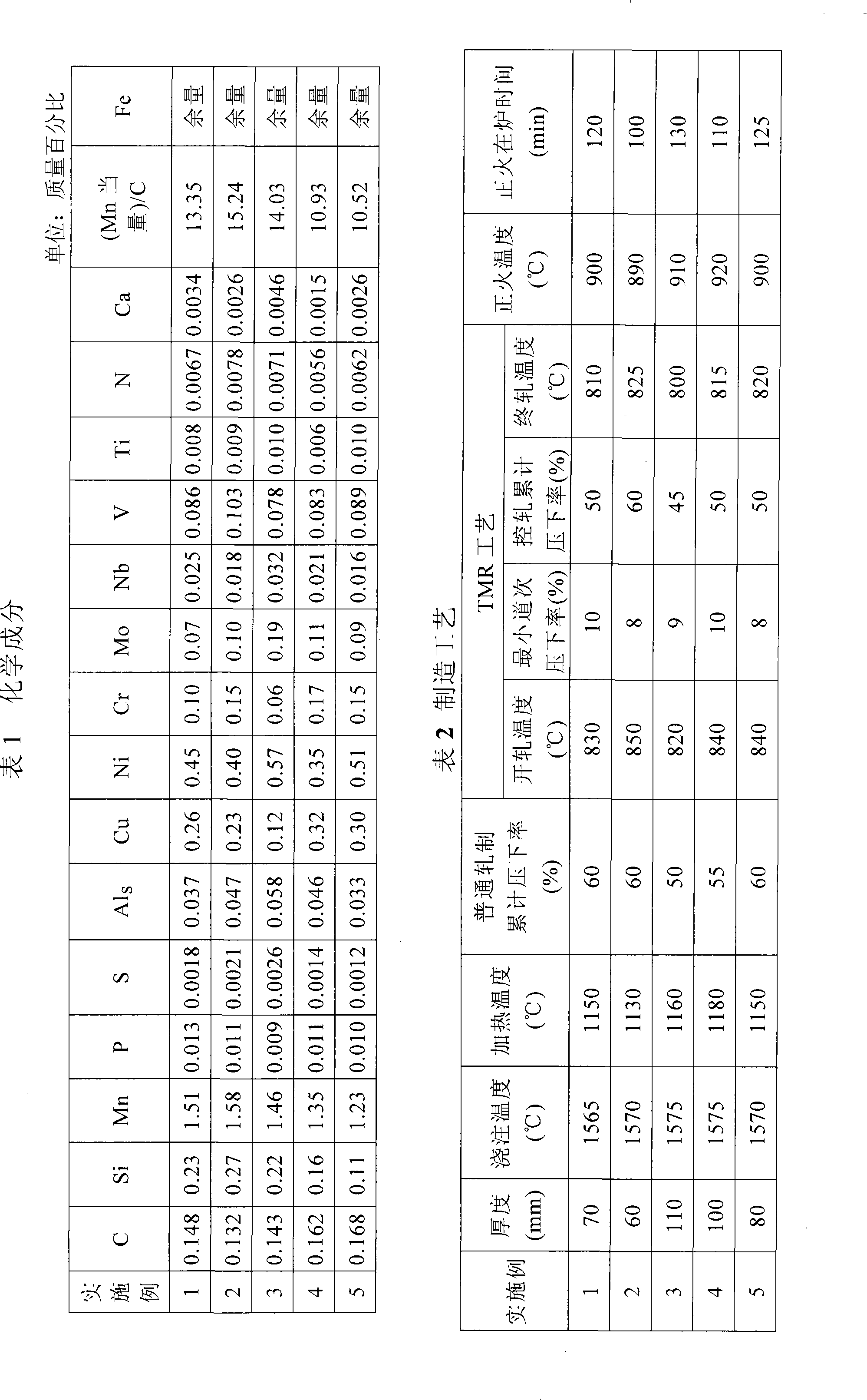

[0073] Examples of the present invention refer to Table 1 and Table 2.

[0074] Manufacturing process of the present invention is as follows:

[0075] TDS molten iron deep desulfurization → converter smelting, LF ladle refining furnace → RH vacuum refining (feeding Si-Ca wire) → die casting → slab off-line finishing → slab cutting to length → heating, high pressure water descaling → ordinary rolling Manufacture, controlled rolling (TMR)→steel stack slow cooling / pit slow cooling→automatic ultrasonic testing (AUT) / manual ultrasonic testing (MUT)→steel plate trimming, cutting head and tail→rough shot blasting to remove scale on the steel plate surface→ Normalizing heat treatment (N)→sampling and performance testing→cutting steel plates to length→surface quality and appearance dimensions, marking and testing→delivery.

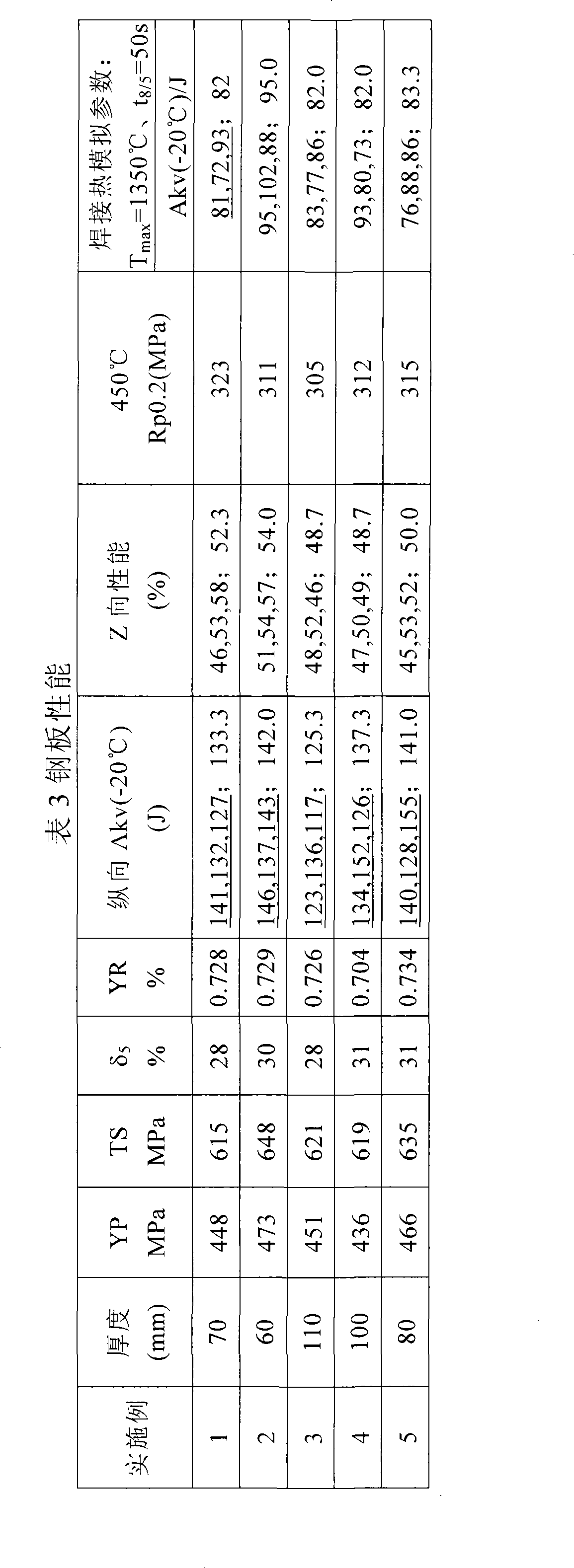

[0076]For the examples of the present invention, refer to Table 1 and Table 2, and Table 3 shows the performance of the steel plate of the present invention.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com