Middle and high temperature super-thick steel plate with excellent radiation resistance and manufacturing method thereof

A technology of extra-thick steel plate and manufacturing method, which is applied in the direction of manufacturing tools, temperature control, and control of pouring molten metal from a casting ladle, etc., can solve the problems of on-site welding environment deterioration, tempering embrittlement, and no guarantee of how to ensure it. Achieve the effect of excellent fatigue creep resistance and excellent strength and toughness matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

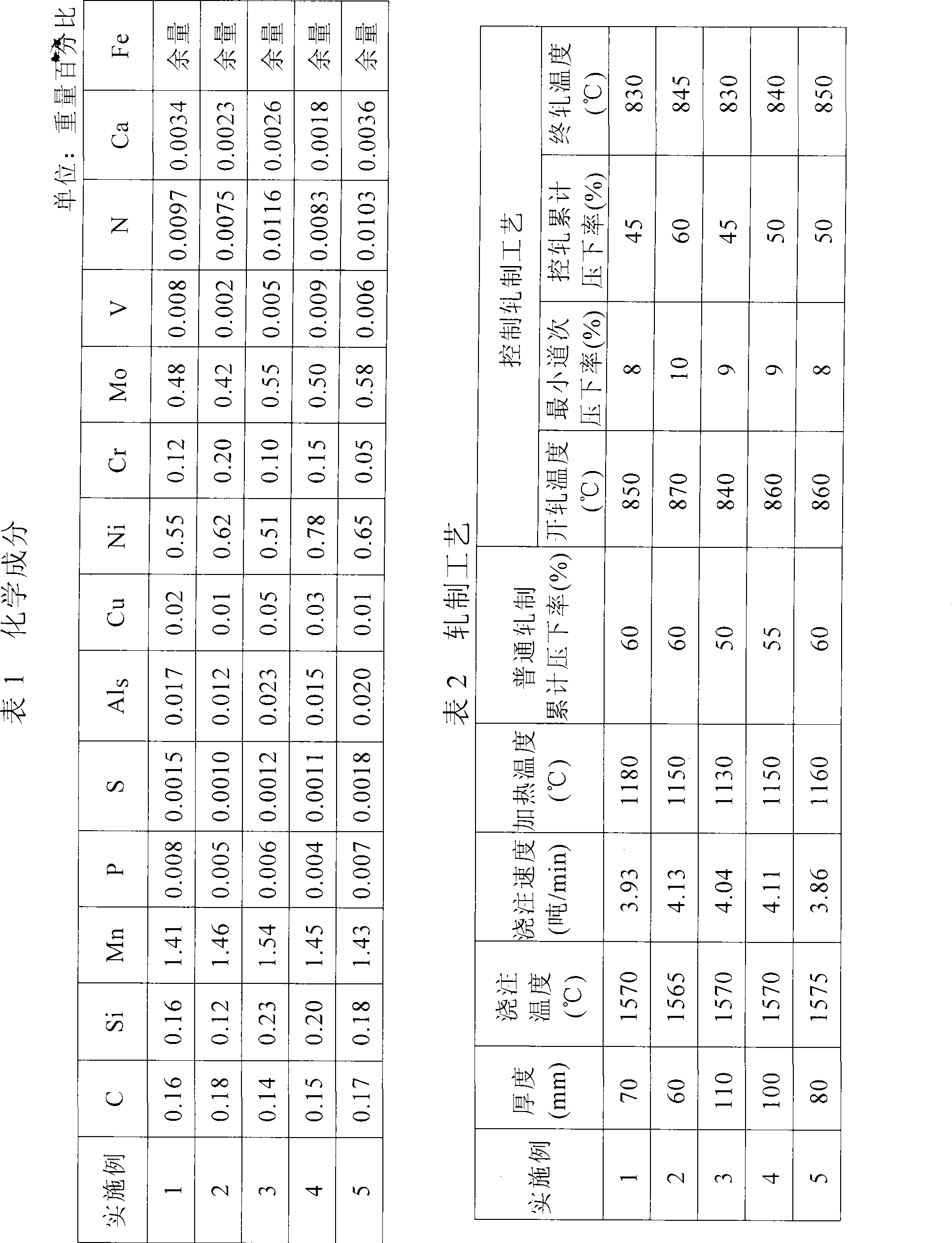

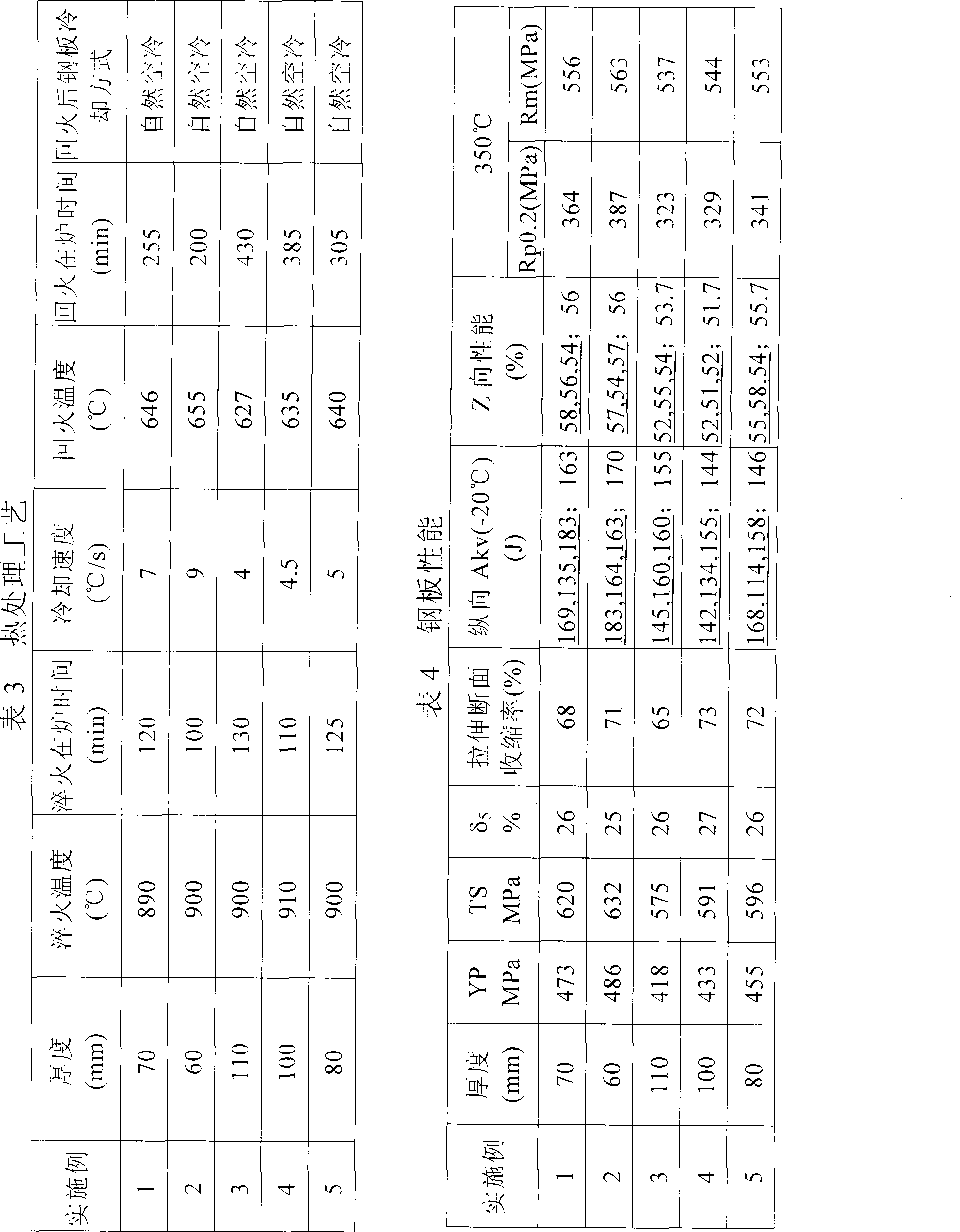

[0059] Embodiments of the present invention refer to Table 1~Table 4 and figure 1 .

[0060] According to the technical characteristics of the steel plate of the present invention, the extra-thick steel plate for medium and high temperature containers is combined with reasonable alloy element combination design and controlled rolling and heat treatment process to obtain excellent base metal steel plate strength and toughness, strong plasticity matching and low yield ratio. Anti-neutron radiation embrittlement, anti-fatigue creep performance, anti-temper embrittlement, anti-hydrogen embrittlement and welding processability are also excellent; in this way, it can not only reduce the steel plate manufacturing cost, shorten the steel plate manufacturing cycle, but also reduce It reduces the difficulty of steel plate production organization; more importantly, it improves the welding process of extra-thick steel plates, saves the user's component manufacturing cost, shortens the use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com