Weld metal having excellent temper embrittlement resistance

一种焊接金属、特性的技术,应用在焊接金属领域,能够解决未考虑耐回火脆化特性等问题,达到优异耐回火脆化特性、提高韧性、特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] Hereinafter, the present invention is described in more detail through the examples, but the following examples do not limit the nature of the present invention, and can also be appropriately modified and implemented within the scope of being able to meet the purpose of the foregoing and the following, and these are all included in the scope of the present invention. within the range of technology.

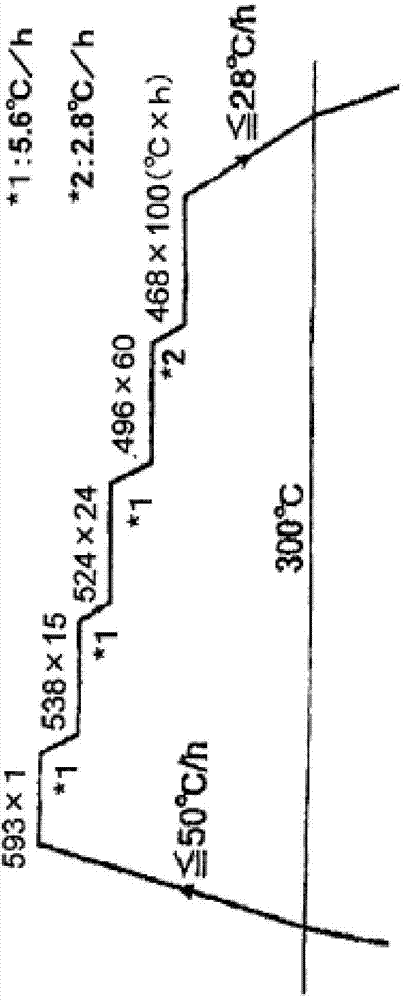

[0087] Using base metals having the following compositions, weld metals were produced under the welding conditions described below, and after heat treatment, various characteristics were evaluated.

[0088] [Base material composition (mass%)]

[0089] C: 0.12%, Si: 0.23%, Mn: 0.48%, P: 0.004%, S: 0.005%, Cu: 0.04%, Al: <0.002%, Ni: 0.08%, Cr: 2.25%, Mo: 0.99% , V: 0.004%, Ti: 0.002%, Nb: 0.005% (balance: iron and unavoidable impurities)

[0090] [Soldering conditions]

[0091] Welding method: automatic shielded metal arc welding (SMAW)

[0092] Base material thickness: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com