Preparation method of titanium-aluminum alloy target material

A technology of titanium-aluminum alloy and target material, which is applied in the field of preparation of titanium-aluminum alloy target material, can solve the problems of high process cost, cumbersome process, and long process, and achieve simple production process control, uniform grain structure, and low hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0032] A method for preparing a titanium-aluminum alloy target, comprising a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a cutting step, an alloying diffusion heat treatment step and a machine Machining and trimming steps.

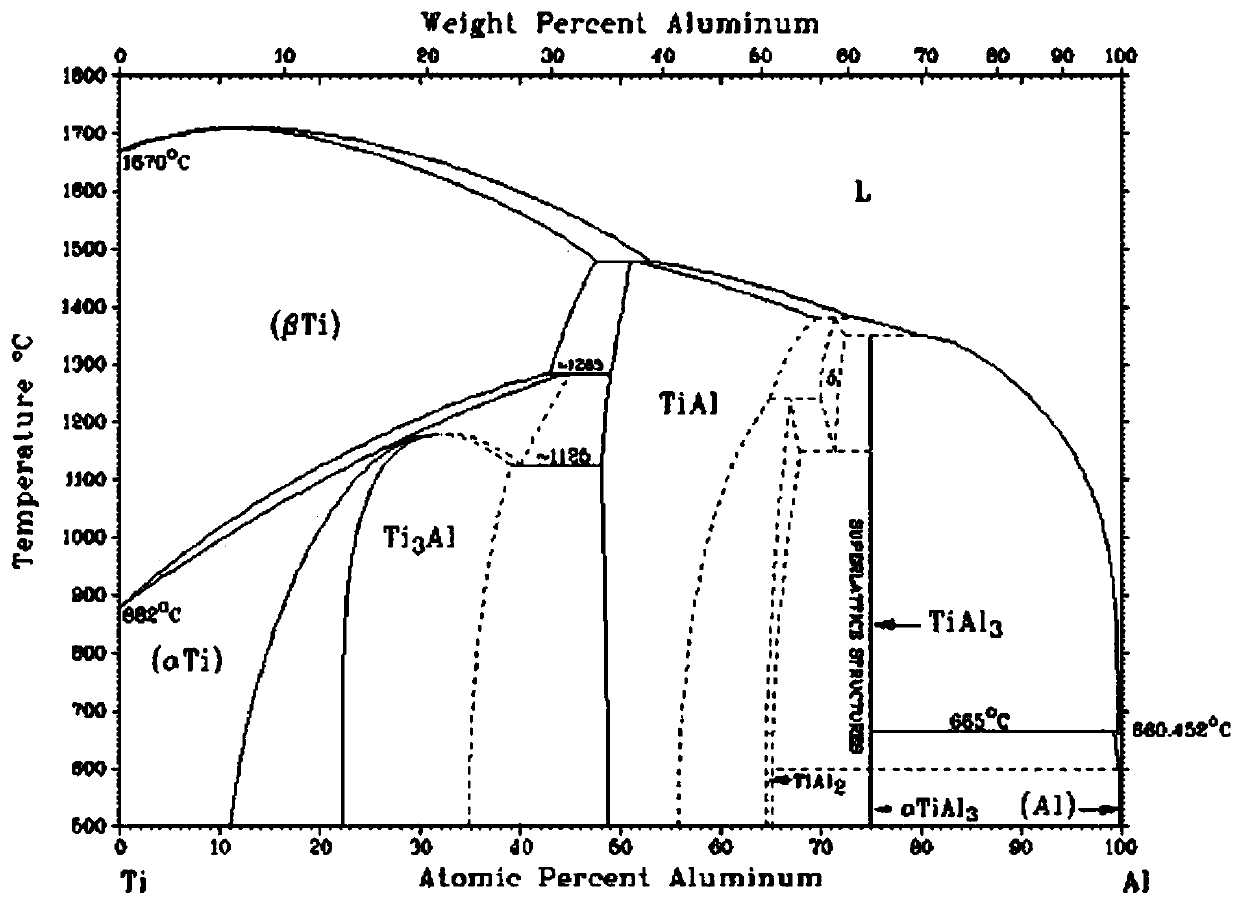

[0033] Titanium aluminum targets are widely used in the fields of tools and decorative coatings. Titanium-aluminum alloy has low density, high strength and hardness, and has good wear resistance. Coating a layer of titanium-aluminum alloy on the surface of ordinary knives can enhance the surface hardness of the knives, make the knives sharper, and effectively extend the use time of the knives . Under different atmospheres, titanium-aluminum alloy targets can form decorative films of different colors such as yellow, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com