A low-cost long-period fiber grating fabrication method

A manufacturing method and fiber grating technology, which are applied in cladding optical fibers, optical waveguides, light guides, optics, etc., can solve the problems of complex process, high processing cost, and difficulty in practical application, and achieve simple control of the manufacturing process, reduction of manufacturing costs, and manufacturing The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

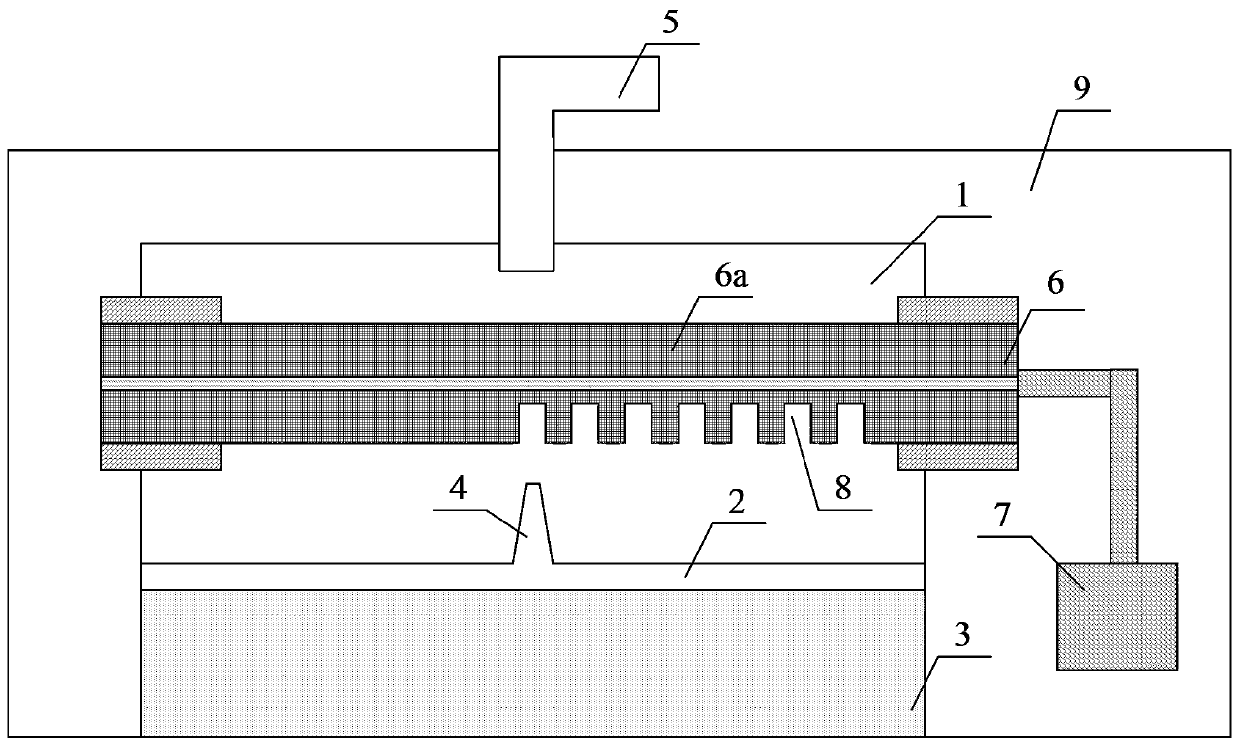

[0029] Such as figure 1 As shown, the manufacturing steps of the long-period fiber grating in this embodiment are as follows:

[0030] An airtight container 1 is arranged, and the airtight container 1 is divided into upper and lower parts by a cover plate 2, and micropores 4 with a diameter of 30 μm are arranged on the cover plate 2, and the upper and lower parts of the airtight container are connected through the micropores; in the airtight container The lower part of the lower part is filled with an etching solution 3, and an optical fiber insertion hole for inserting an optical fiber is provided on the side wall of the upper part; an air extraction hole 5 is provided on the top of the airtight container 1, directly above the microhole 4;

[0031] Specifically, mix 200mL of hydrofluoric acid solution with a mass concentration of 30% and 50mL of a glucose solution with a mass concentration of 10% as an etching solution, add it to the lower part of the airtight container 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com