Recordable optical recording carrier and method for manufacturing recordable optical recording carrier compatible with CD-R

A manufacturing method and optical disc technology, which are applied in the fields of optical record carrier manufacturing, optical recording/reproduction, optical recording/reproduction/erasing methods, etc., which can solve the problems of inability to maintain recorded data, affecting the correctness of read signals, increase in production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] [Embodiment 1: High Density Optical Disk]

[0085] Using the present invention, high-density optical discs can be developed, and the proven method is as follows: In the laser engraving process, two laser beams are used to expose the glass substrate 31 coated with photoresist. The laser beam used for recording the main track 12 has a relatively high power and does not need to add a wobble signal. And the laser beam that is used to record sub-track 13 uses lower power, and the ratio of its power and the power of the laser beam that is used to record main track 12 must be determined according to the depth of the track to be formed after development. Considering the power distribution characteristics of the laser beam and development control and other factors, the best form is to form a relatively deep and wide U-shaped groove on the main track 12, while the sub-track 13 forms a half-height width and depth that are both within the main track 12. 1 / 2 of the V-shaped groove,...

Embodiment 2

[0088] [Embodiment 2: Compatible with the optical disc of CDR format]

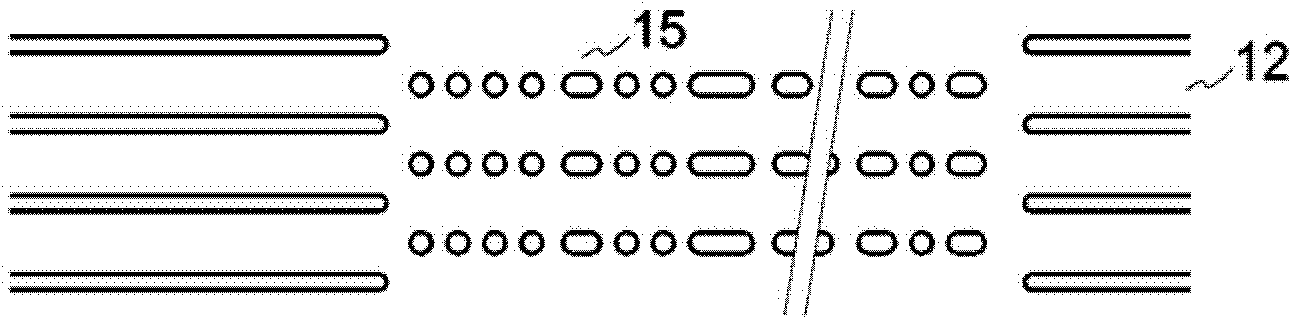

[0089] Figure 4 It is a schematic diagram showing the frequency modulation method of the existing CDR optical disc. Figure 5 It is a waveform representing the wobble signal of a conventional CDR optical disk. As mentioned above, the CDR optical disc uses FM modulation to modulate the control data (absolute time code data, ATIP data) in the swing of the track. The track type and the read control signal are as follows: Figure 4 shown. The control data first undergoes channel coding (biphase code modulation) to become a data string 22 of binary code. With the frequency of 22050Hz as the carrier wave 23, the data string 22 of the binary code through the channel encoding is FM modulated (FM) by the FM modulator 24 to form a modulated wobble signal 25, and then the wobble signal 25 The optics are driven to create a swinging track 26 . The CDR track itself has a periodic side-to-side swing, and the freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com