Steel plate for ship structure and manufacture method thereof

A steel plate and hull technology, which is applied in the steel plate of the hull structure and its manufacturing field, can solve the problems of shrinkage rate not meeting user requirements, deterioration of steel plate welding performance, aggravated segregation of core components, etc., to achieve reasonable chemical composition design and high production efficiency , easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

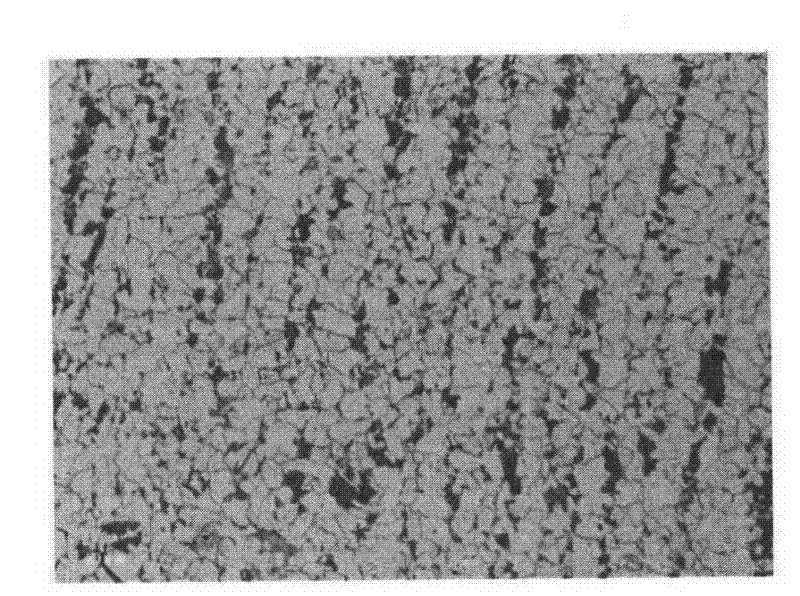

[0048] Example 1: 100mm thick EH36 industrial rolling

[0049] A high-strength, high-toughness, high-area reduction extra-thick ship plate steel, its chemical composition mass percentage content is: C 0.12%, Si 0.36%, Mn 1.45%, P 0.009%, S 0.005%, Nb 0.038%, V 0.033 %, Ti 0.017%, Ni 0.25%, Als 0.038%, and the balance of Fe and unavoidable impurities.

[0050] Billet section size: 300mm×2200mm×3600mm; finished product size: 100mm×2300mm×Lmm.

[0051] The preparation method of the above-mentioned steel plate used for the hull structure is as follows: including smelting, heating, rough rolling, and finish rolling processes, wherein the basicity of the refining slag is controlled at 2.5, the long nozzle for ladle casting is protected by Ar seal, and the submerged nozzle of the tundish is added with Ar. Sealed full protection pouring, the tundish superheat is 19 ℃. The subsequent rolling, water cooling and heat treatment processes are shown in Table 1. The steel properties of ...

Embodiment 2

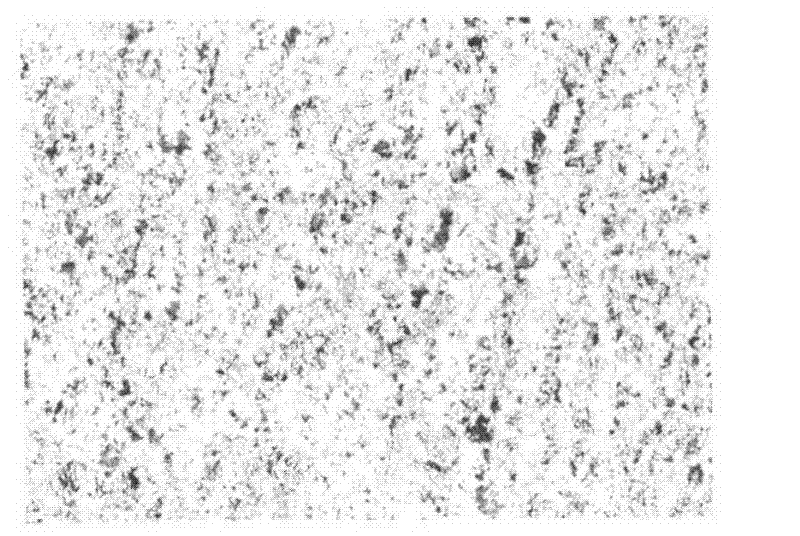

[0053] Example 2: 80mm thick EH36 industrial rolling

[0054] A controlled-rolled extra-thick high-strength ship plate steel, the mass percent of its chemical composition is: C 0.13%, Si 0.36%, Mn 1.45%, P 0.009%, S 0.004%, Nb 0.038%, V 0.033%, Ti 0.017%, Ni 0.31%, Als 0.038%, the balance is Fe and unavoidable impurities.

[0055] Billet section size: 300mm×2200mm×3600mm; finished product size: 80mm×2500mm×Lmm.

[0056] The preparation method of the above-mentioned control-rolled extra-thick high-strength ship plate steel is as follows: including smelting, heating, rough rolling, and finish rolling processes; wherein the basicity of the refining slag is controlled at 2.8, the long nozzle for ladle pouring is protected by an Ar seal, and the tundish is immersed The full-protection pouring with double-type nozzle and Ar seal, the superheat of the tundish is 23°C; the subsequent rolling, water cooling and heat treatment processes are shown in Table 1. The steel properties of ...

Embodiment 3

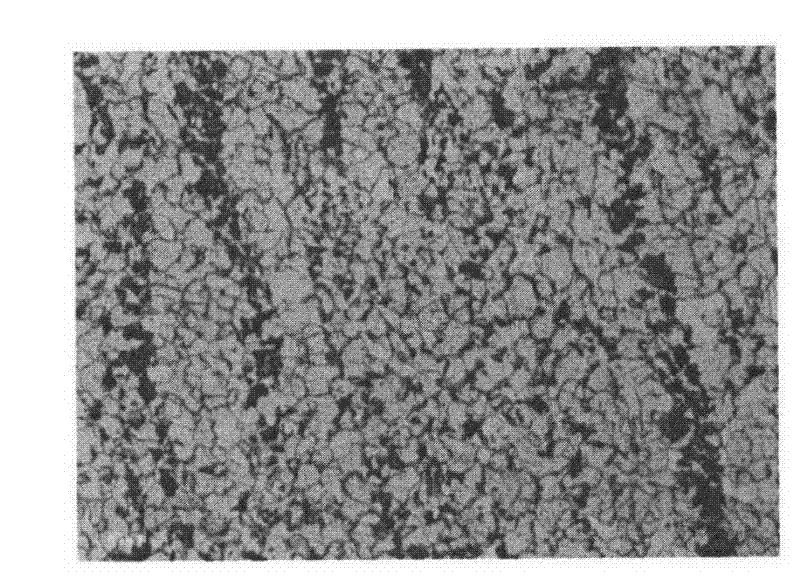

[0057] Example 3: 60mm thick EH36 industrial rolling

[0058] A controlled-rolling type extra-thick high-strength ship plate steel, the mass percentage of its chemical composition is: C 0.15%, Si 0.32%, Mn 1.43%, P 0.010%, S 0.003%, Nb 0.033%, V 0.031%, Ti 0.015%, Ni 0.29%, Als 0.037%, the balance is Fe and unavoidable impurities.

[0059] Billet section size: 300mm×2200mm×3600mm; finished product size: 60mm×2800mm×Lmm.

[0060] The preparation method of the above-mentioned control-rolled extra-thick high-strength ship plate steel is as follows: including smelting, heating, rough rolling, and finish rolling processes; wherein the basicity of the refining slag is controlled at 3.7, the long nozzle for ladle pouring is protected by an Ar seal, and the tundish is immersed Full protection pouring with type nozzle and Ar seal, the superheat of the tundish is 21°C. The subsequent rolling, water cooling and heat treatment processes are shown in Table 1. The properties of the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com