Waterborne polyurethane and preparation method and application thereof

A water-based polyurethane and linear technology, applied in the field of water-based polyurethane and its preparation, can solve problems such as easy gel formation, difficult dispersion, excessive viscosity of prepolymer, etc., and achieve soft surface touch, supple leather finish and good physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

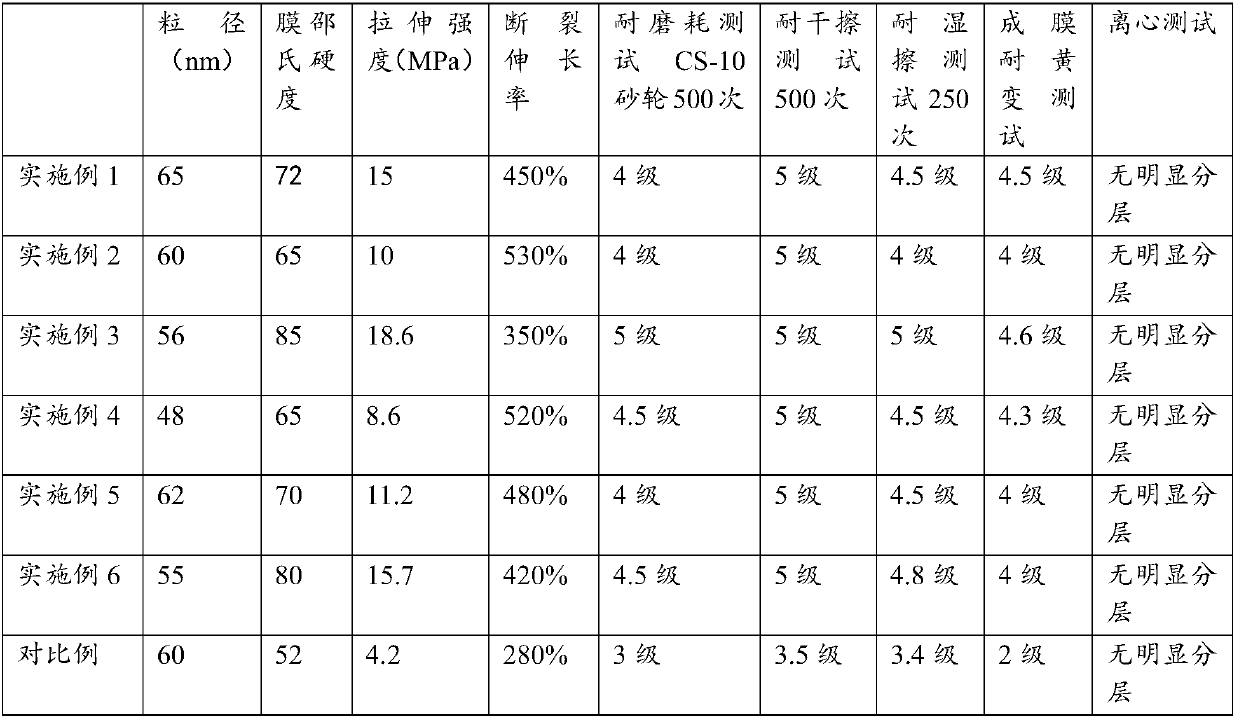

Examples

preparation example Construction

[0015] Some embodiments of the present invention provide a kind of preparation method of waterborne polyurethane, it comprises the following steps:

[0016] S1. Polymerize the HDI trimer or IPDI trimer with polyethylene glycol to obtain a hydroxyl-terminated trifunctional polymer, and then combine the hydroxyl-terminated trifunctional polymer with hexamethylene diisocyanate (HDI ) or isophorone diisocyanate (IPDI) to form an isocyanate-terminated trifunctional polymer and adjust the viscosity with acetone.

[0017] S2. Reacting hexamethylene diisocyanate or isophorone diisocyanate with diol monomers and hydrophilic monomers to obtain a linear waterborne polyurethane prepolymer, and adjusting the viscosity with acetone.

[0018] S3. After carrying out the cross-linking reaction of the isocyanate-terminated trifunctional polymer with adjusted over-viscosity and the linear water-based polyurethane prepolymer with adjusted over-viscosity under the action of a chain extender, aceto...

Embodiment 1

[0059] Add IPDI trimer and polyethylene glycol with a molecular weight of 600 in a molar ratio of 1:3 into a three-necked flask, stir and heat up to 80°C for 3 hours to obtain a hydroxyl-terminated trifunctional polymer, and then add polyethylene glycol Alcohol equimolar amount of HDI, continue to react at 85°C for 3 hours to form isocyanate-terminated trifunctional polymer, cool down to 60°C and add acetone to dilute and continue to cool down to room temperature to obtain Component A. Wherein, acetone is 10% of the total mass of the reactants for forming the isocyanate-terminated trifunctional polymer.

[0060] In a 250m1 four-neck flask equipped with a stirrer, a condensing reflux tube, and a thermocouple, add IPDI, 2000 molecular weight PTMEG and DMPA and react at 90°C for 3 hours to produce a linear water-based polyurethane prepolymer, then cool down to 60°C and add acetone to reduce the temperature. Sticky, Component B is obtained. Wherein, the molar ratio of IPDI and PT...

Embodiment 2

[0063] Add the IPDI trimer and polyethylene glycol with a molecular weight of 1200 in a molar ratio of 1:3 into a three-necked flask, stir and heat up to 76°C for 2.5 hours to obtain a hydroxyl-terminated trifunctional polymer, and then add polyethylene glycol Alcohol equivalent molar amount of HDI was reacted at 90°C for 2.5 hours to form an isocyanate-terminated trifunctional polymer. Cool down to 60°C and add acetone to dilute and continue to cool down to room temperature to obtain Component A. Wherein, acetone accounts for 20% of the total mass of the reactants for forming the isocyanate-terminated trifunctional polymer.

[0064] Add HDI, 2000 molecular weight PCL and DMPA to a 250m1 four-neck flask equipped with a stirrer, condensing reflux tube, and thermocouple, and react at 90°C for 3 hours to produce a linear water-based polyurethane prepolymer, then cool down to 60°C and add acetone to reduce the temperature. Sticky, Component B is obtained. Wherein, the molar ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com