Automobile die

A technology for automobile molds and air pipes, which is applied to household appliances, other household appliances, household components, etc., and can solve problems such as wasting water, increasing manufacturing costs, and reducing the molding efficiency of plastic melts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

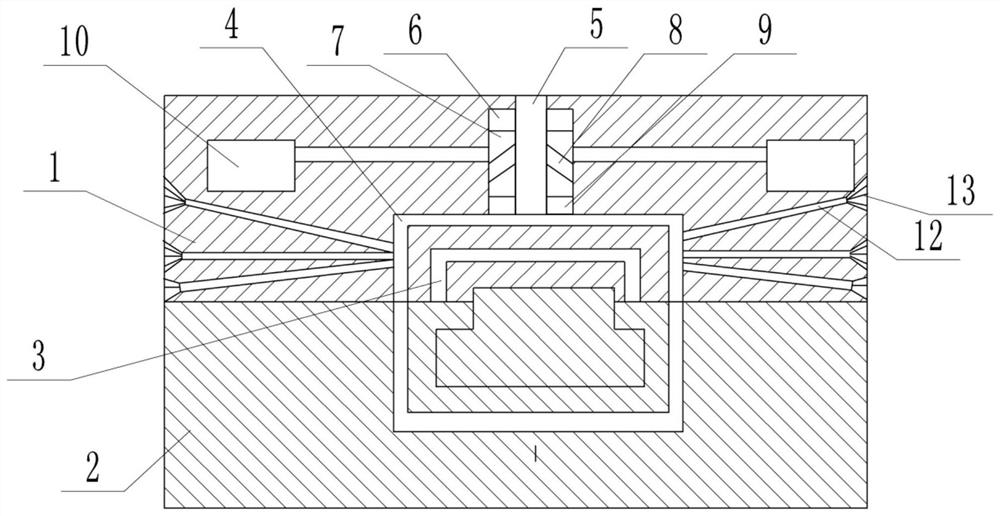

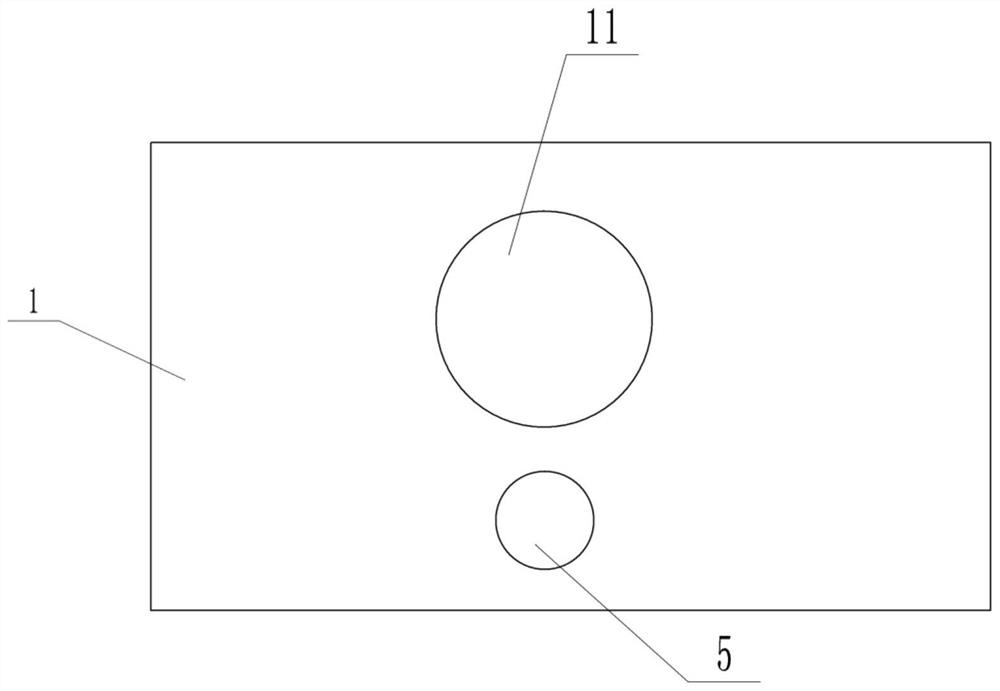

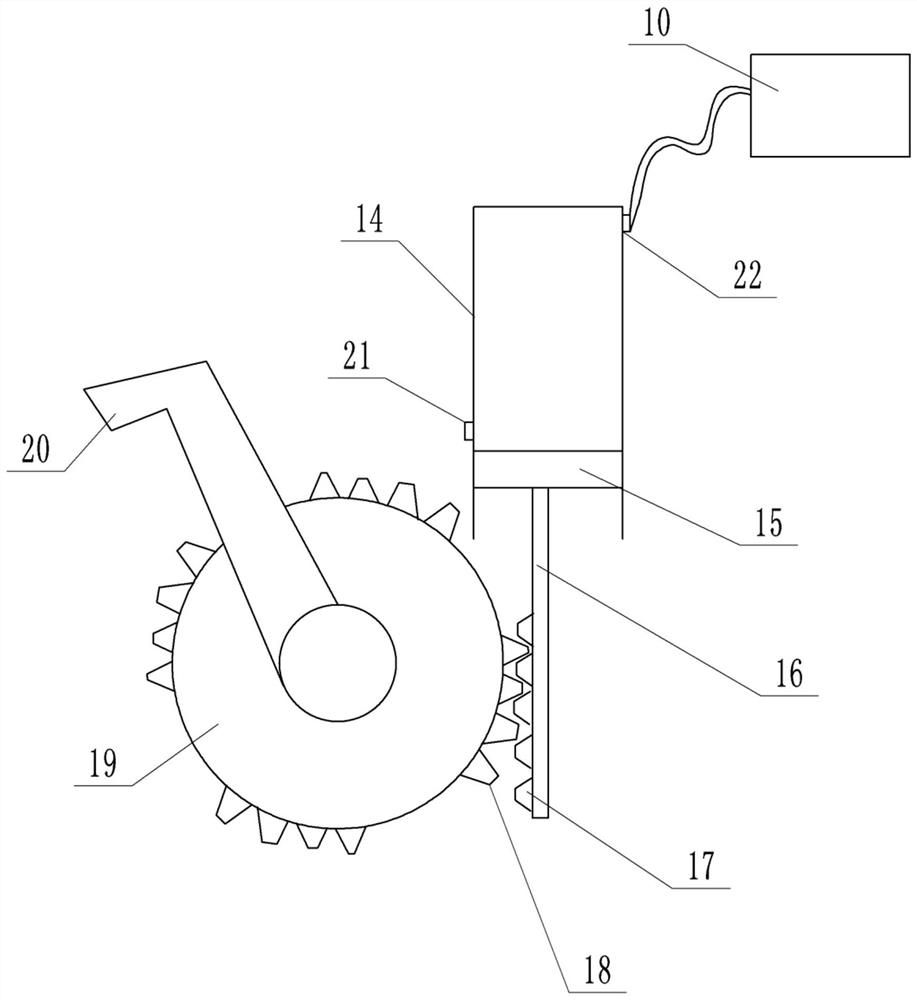

[0027] Such as figure 1 As shown, a kind of automobile mould, comprises upper mold 1 and lower mold 2, and when said upper mold 1 and lower mold 2 are engaged, forms closed forming cavity 3 between upper mold 1 and lower mold 2, and said upper mold 1 An injection channel 11 and an air channel 5 are provided on the top, and the injection channel 11 communicates with the molding cavity 3. The upper mold 1 is provided with a heat conduction channel 4, and the heat conduction channel 4 is covered above the molding cavity 3. The air The channel 5 communicates with the heat conduction channel 4, and the inner wall of the air channel 5 is provided with symmetrical openings, and the two sides of the outer wall of the air channel 5 are provided with symmetrical adjustment chute 6, and the two sides of the side walls of each adjustment chute 6 A symmetrical port is provided on the side, and the bottom of the adjustment chute 6 is offset against the heat conduction channel 4. An air bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com