Injection molding machine separated hot runner module for plastic processing

A separate technology for injection molding machines, applied in the field of separate hot runner modules for injection molding machines for plastic processing, can solve the problems of insufficient heating of solid plastics, inconvenient separation methods, slow time, etc., to achieve easy shape fixation, separation, and safety Efficient injection molding operation, the effect of improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

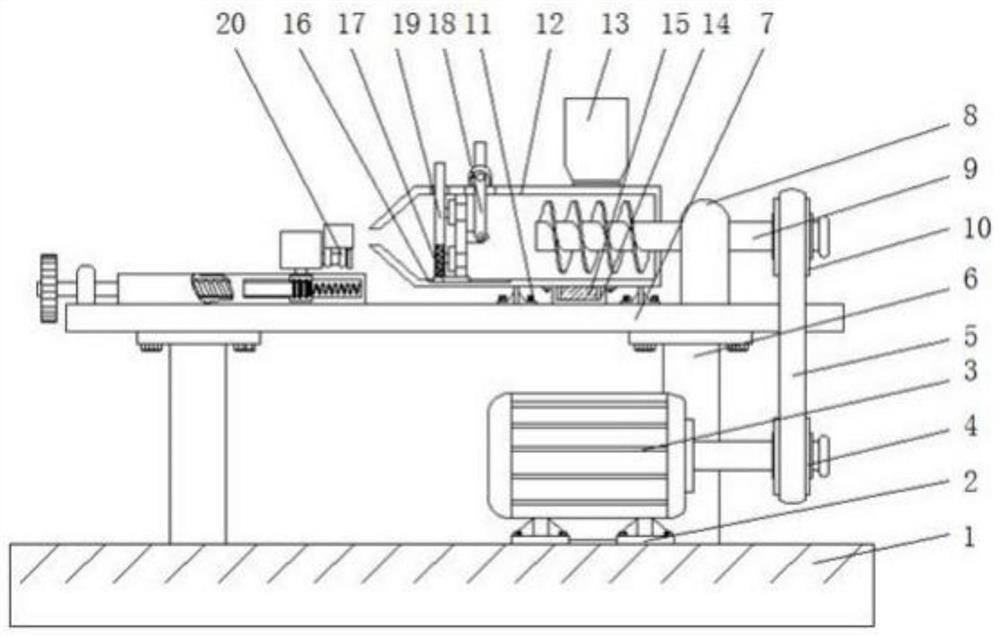

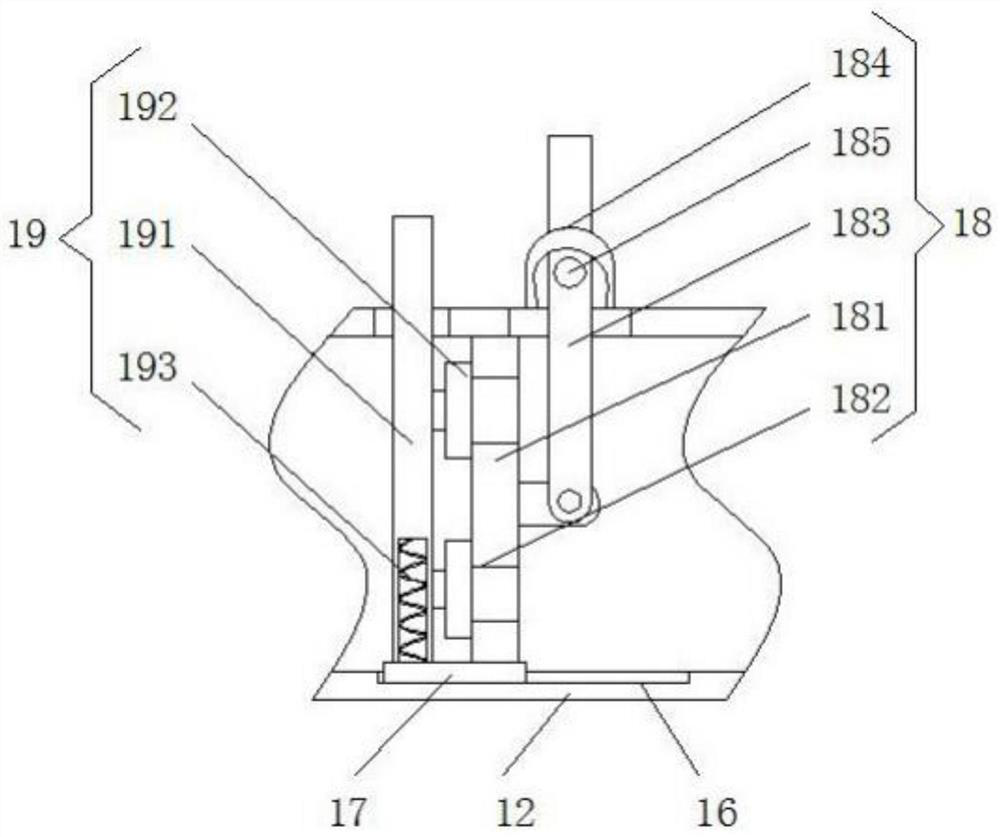

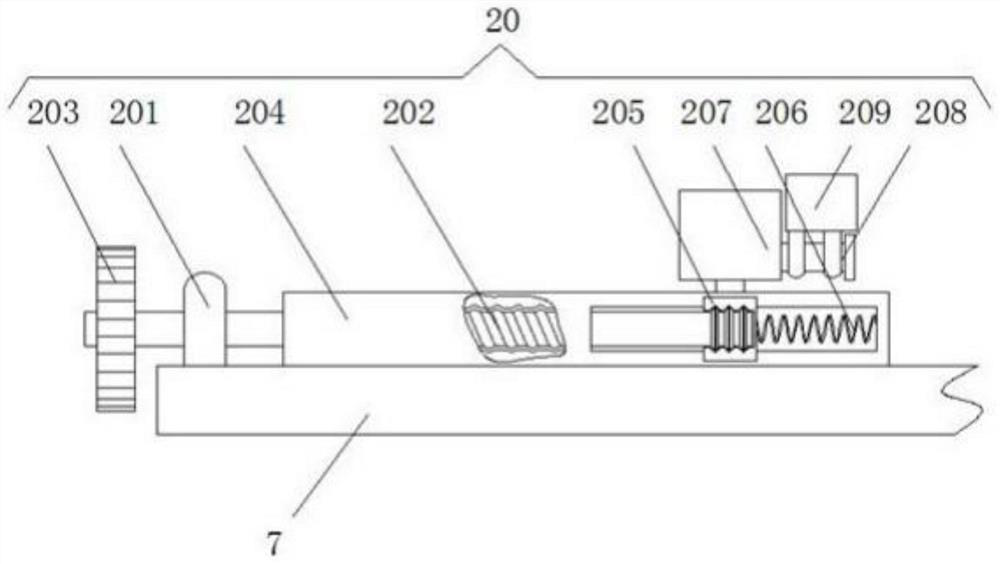

[0017] like Figure 1-3As shown, a separate hot runner module of an injection molding machine for plastic processing includes a workbench 1, and a tripod I2 is fixedly installed in the middle of the top of the workbench 1. There are two tripods I2, and the two tripods I2 The top is fixedly connected with both sides of the bottom of the engine 3 respectively, the output shaft of the engine 3 is fixedly sleeved with a driving wheel 4, and the outer edge of the driving wheel 4 is movably connected with a belt 5, the length of the belt 5 is 1m, and the belt 5 and the bottom plate 7 They are perpendicular to each other, and the belt 5 is not in contact with the support frame 6 and the bottom plate 7. Through the structure that the belt 5 is movably connected to the outer ring of the driving wheel 4 and the driven wheel 10, the function of providing kin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com