Thick film heater

A thick-film heater and thick-film technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to improve cleaning efficiency, inability to realize rapid adjustment of liquid temperature, inability to accurately control liquid temperature, etc. problem, to achieve the effect of short cooling time, short temperature rising time and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

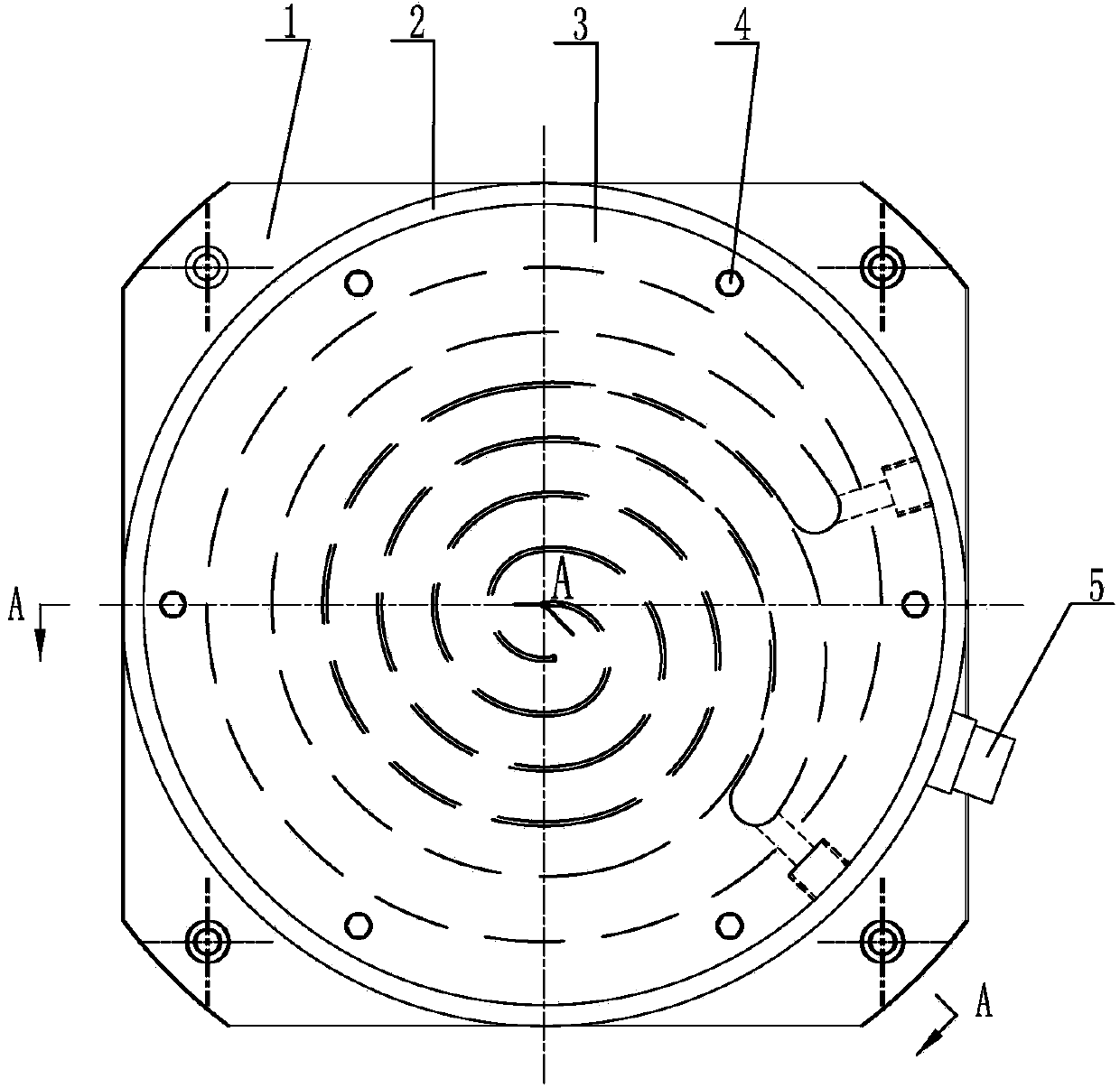

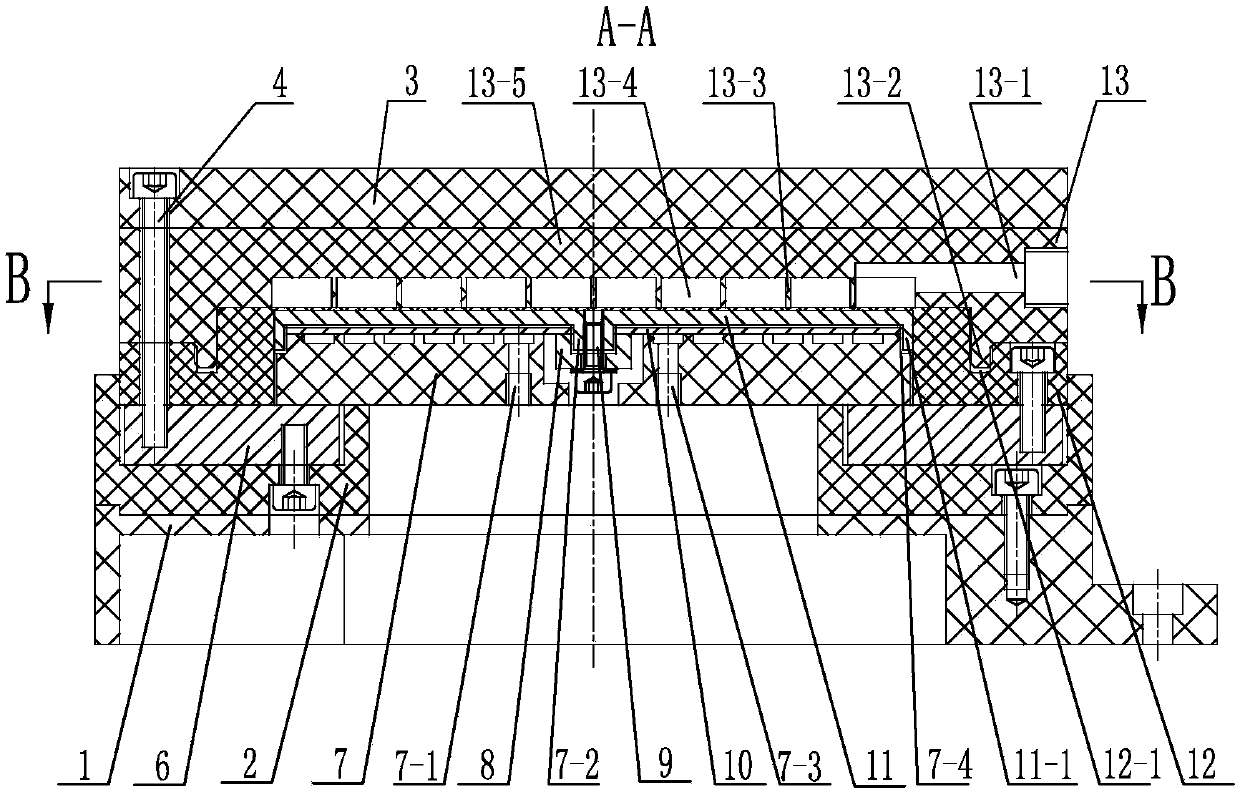

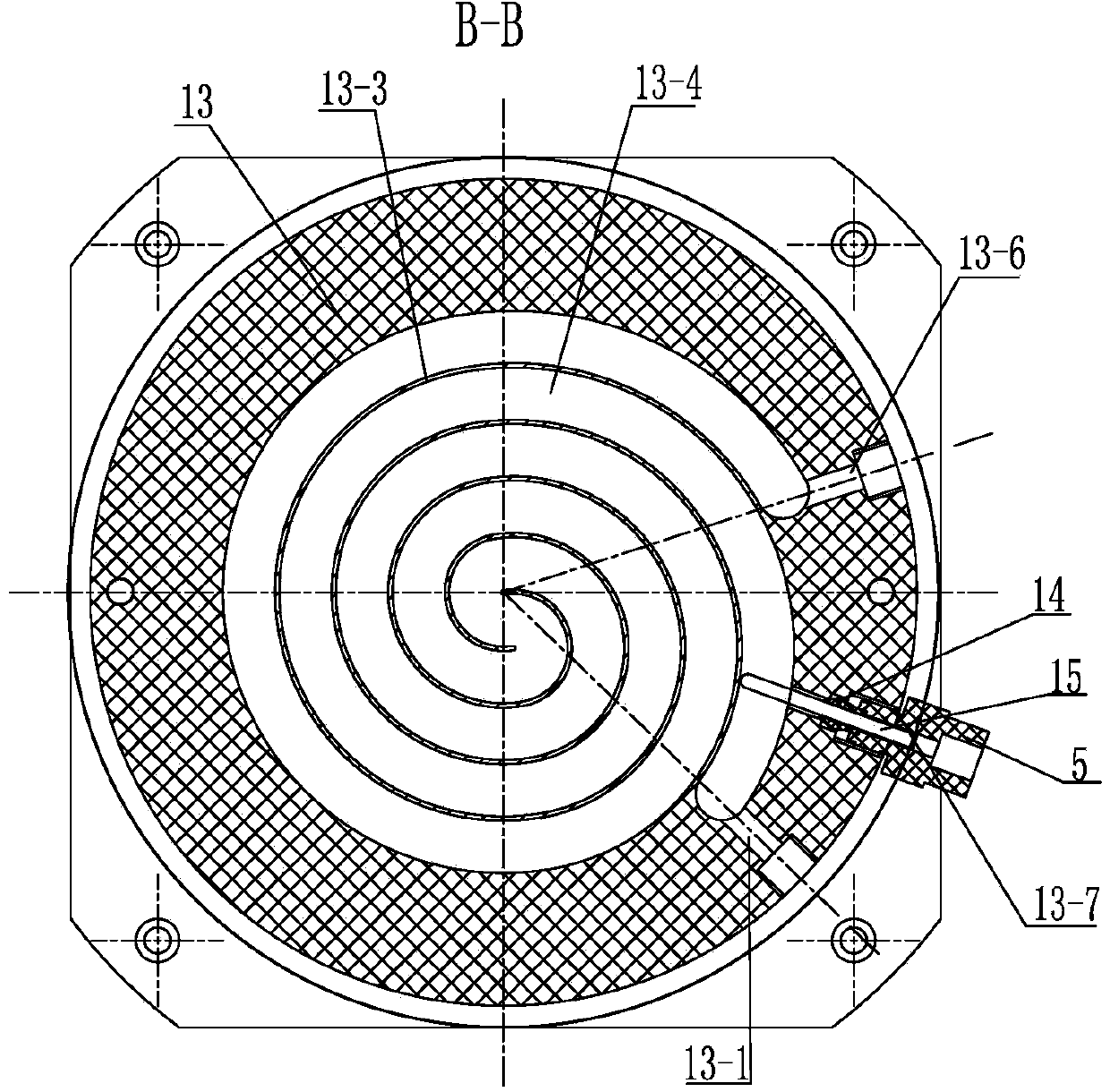

[0020] See Figure 1~3 As shown, the thick film heater of the present invention includes a thick film heating disc 10 , a heating disc press block 7 arranged at the bottom of the thick film heating disc 10 , a heat conduction disc 11 arranged at the upper part of the thick film heating disc 10 and a heating pool 13 . See figure 2 As shown, an air groove is provided on the surface where the heating plate pressing block 7 of the present invention is connected with the thick film heating plate 10, and the air inlet port 7-1 and the air outlet port 7-3 on the heating plate pressing block 7 communicate with the air groove, The air groove on the heating plate pressing block 7 of the present invention rotates outward along the center of the heating plate pressing block 7 and forms a spiral air groove, or the air groove on the heating plate pressing block 7 is a positive plate connecting more than two U-shaped air grooves. Groove, make the air groove on the heating plate pressing bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com