Cooling device for processing paint stripping-free jointing clamps of enameled wires

A cooling device and terminal clip technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of short time consumption and long time consumption of cooling devices, and achieve short time consumption, good heat dissipation effect, and large heat dissipation range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

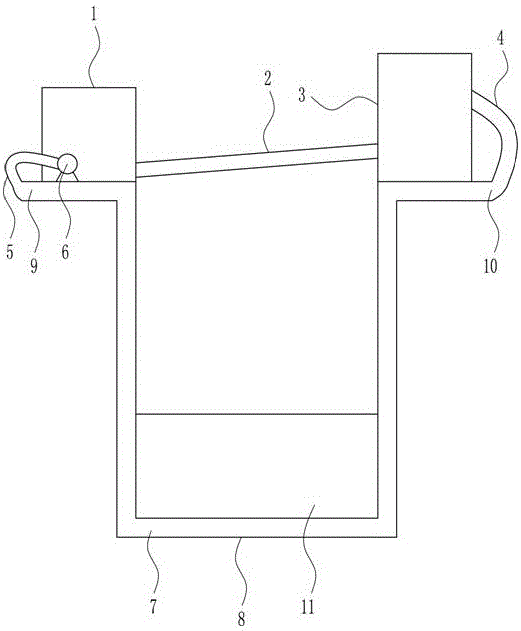

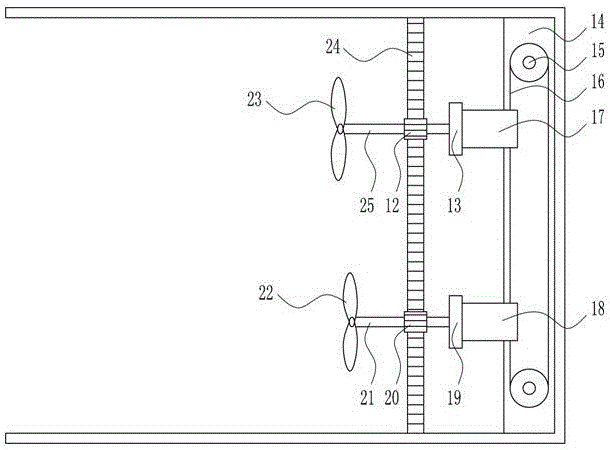

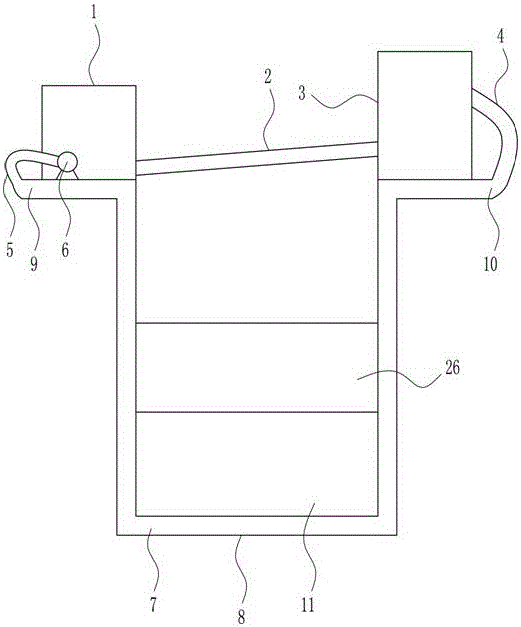

[0030] A cooling device for processing paint-stripping wire clips without peeling paint, such as Figure 1-5 As shown, it includes a water tank 1, a first water pipe 2, a cooling device 3, a water inlet pipe 4, a water outlet pipe 5, a water pump 6, a cooling tank 8 and a cooling device 11; the cooling tank 8 has an inner cavity 7, and the top of the inner cavity 7 The rear end is provided with a water inlet 9, the top and front end of the inner cavity 7 is provided with a water outlet 10, the top and rear side of the cooling tank 8 is provided with a water tank 1, the inner bottom of the water tank 1 is provided with a water pump 6, and the water pump 6 is provided with an outlet pipe 5 and an outlet pipe 5 passes through the rear wall of the water tank 1, the end of the water outlet pipe 5 is connected to the water inlet 9, the cooling device 3 is provided on the front side of the top of the cooling tank 8, the water inlet pipe 4 is provided on the front side of the cooling d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com