A vacuum cooling machine

A vacuum cooler and vacuum cooling technology, applied in the field of coolers, can solve the problems of not being able to quickly pass through the bacterial breeding period, uneven cooling temperature, and large floor space, so as to avoid biochemical reactions, biological fermentation, and cooling time The effect of short length and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

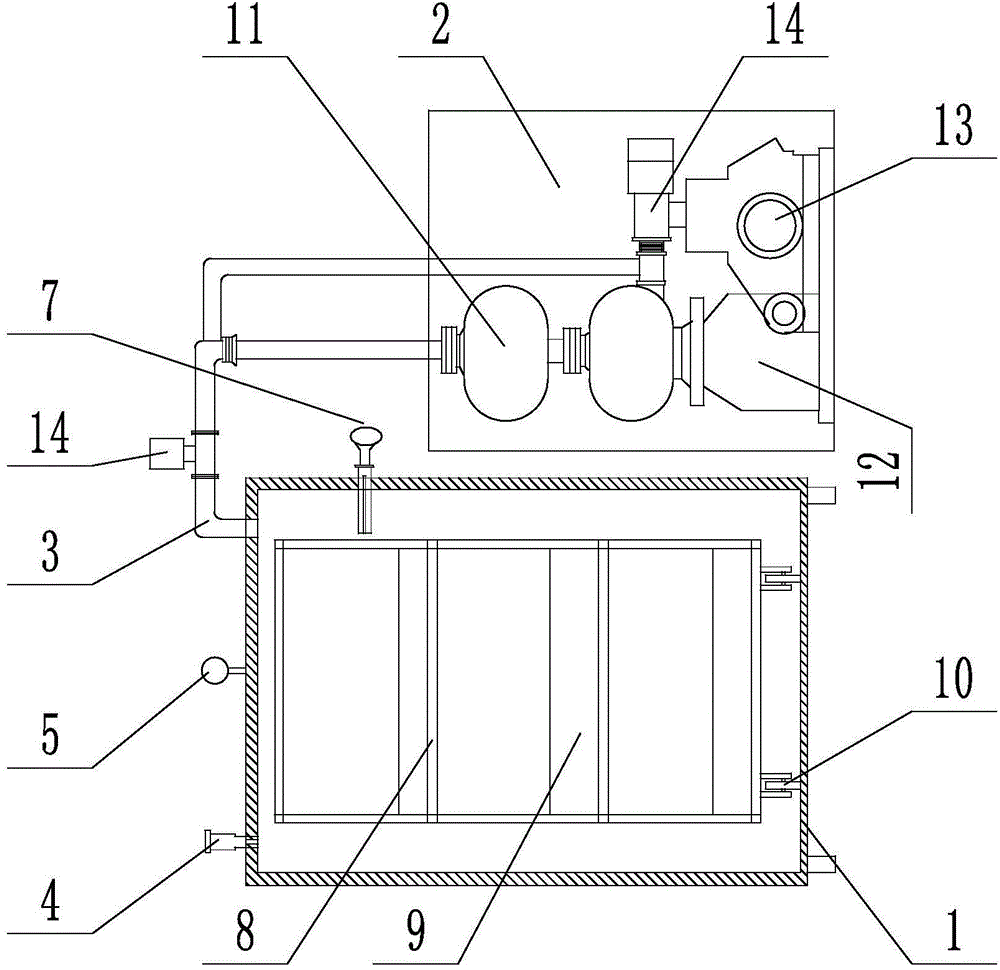

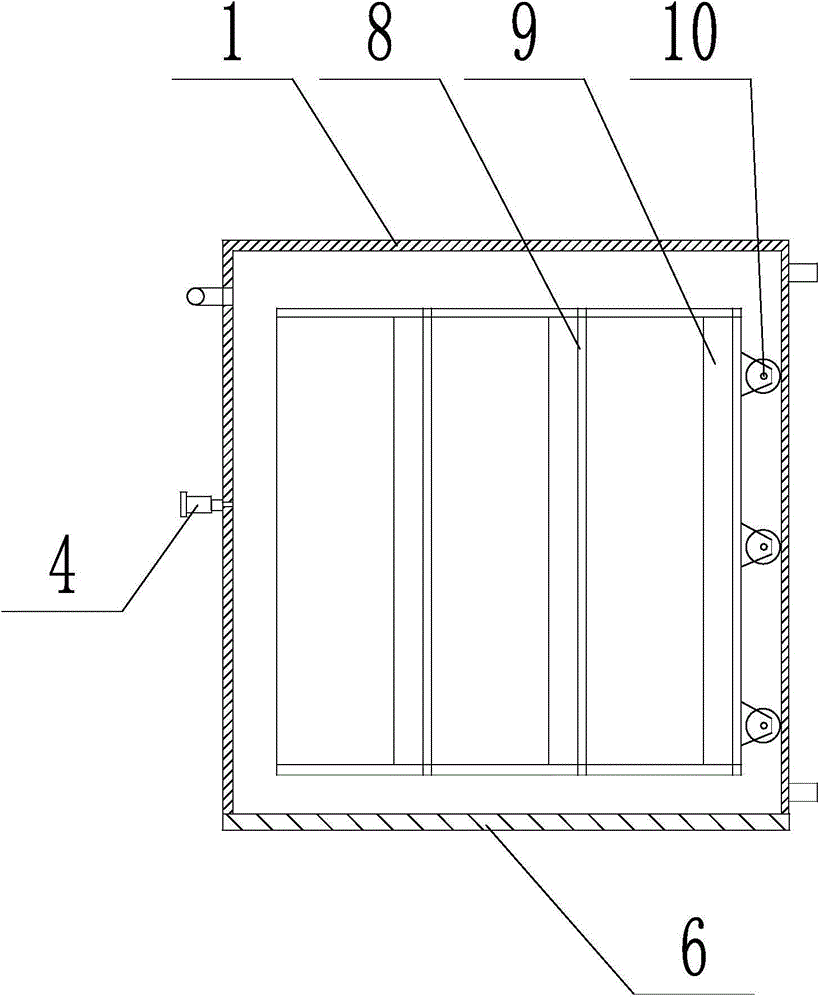

[0012] like figure 1 and 2 As shown, the present invention includes a casing 1 and a vacuum cooling unit 2, the casing 1 and the vacuum cooling unit 2 are connected by an air extraction pipe 3, and an air release valve 4 and a vacuum gauge 5 are installed on the top of the casing 1. 1 is provided with a sealed door 6 on one side, and the temperature sensor 7 is installed on the right wall of the box body 1, and a shelf 8 is arranged inside the box body 1, and a cargo pallet 9 is arranged on the shelf 8, and a casters 10, the vacuum cooling unit 2 includes a condenser 11, a Roots pump 12, a water ring pump 13 and a vacuum solenoid valve 14, a Roots pump 12 is connected below the condenser 11, and the right side of the Roots pump 12 is connected to There is a water ring pump 13, and a vacuum solenoid valve 14 is connected above the water ring pump 13.

[0013] The working principle of the present invention: place the product to be cooled on the cargo pallet 9, place the cargo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com