Stirring shaft, homogenizing and aging machine and sterilizing, homogenizing and aging integrated machine

A stirring shaft and stirring body technology, which is applied in the field of homogeneous aging machine and sterilizing homogeneous aging machine, can solve the problems of prolonging refrigeration time, increasing production cost, affecting refrigeration effect, etc., and achieves accelerated refrigeration speed, strong refrigeration capacity, The effect of short cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

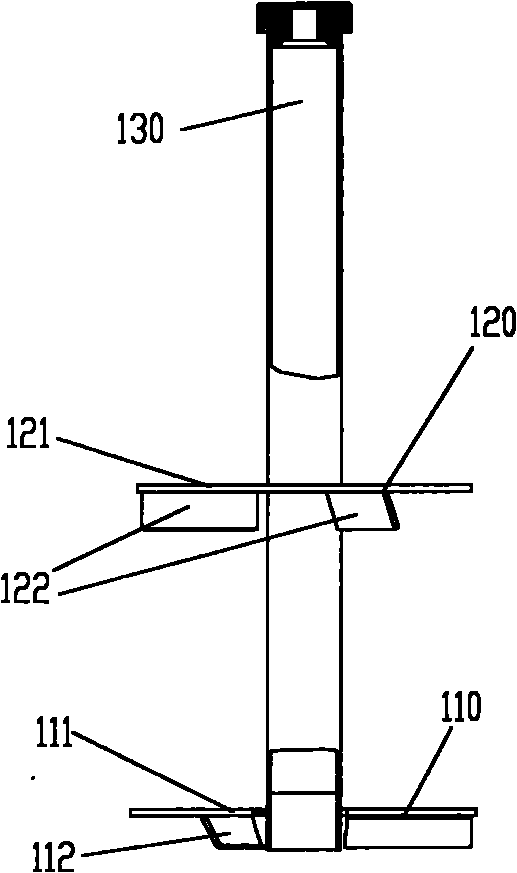

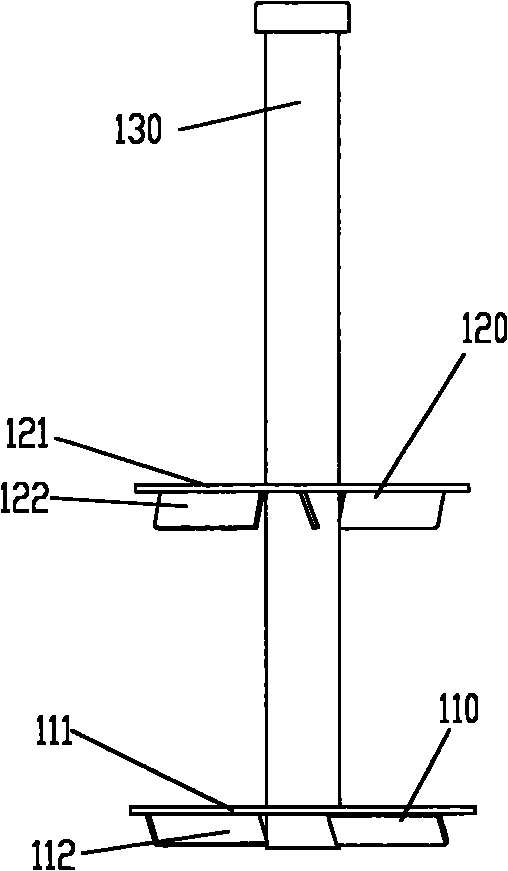

[0024] Such as Figure 1 to Figure 5 As shown, the stirring shaft of the present invention includes: a cylindrical transmission shaft 130, a lower stirring body 110 and an upper stirring body 120 arranged on the transmission shaft 130, and a cover 140 made of plastic installed on the top of the transmission shaft. Wherein the lower stirring body 110 is arranged at the lower end of the transmission shaft 130 .

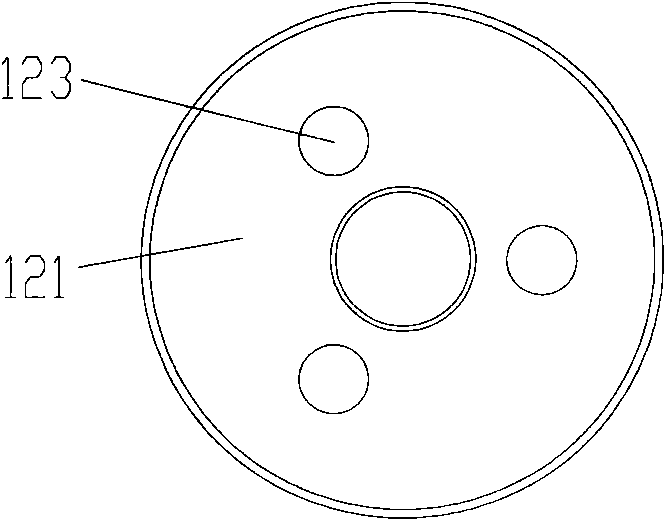

[0025] The lower stirring body 110 includes: a disc-shaped lower stirring body 111 set on the lower end of the transmission shaft 130 and concentric with the transmission shaft 130 , and three strip-shaped lower stirring leaves 112 arranged on the lower surface of the lower stirring body 111 . The three lower stirring leaves 112 are centered on the center of the lower stirring body 111, and are distributed on the lower end surface of the lower stirring body 111 at an equal plane angle, and the circumferential interval angle between any two lower stirring leaves 112 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com