Semiconductor refrigeration high-power LED lamp

A technology of LED lamps and semiconductors, applied in the field of lighting, can solve the problems of scrapped products, difficult work, and weak combination of high-power LED lamps, and achieve the effects of low cost, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

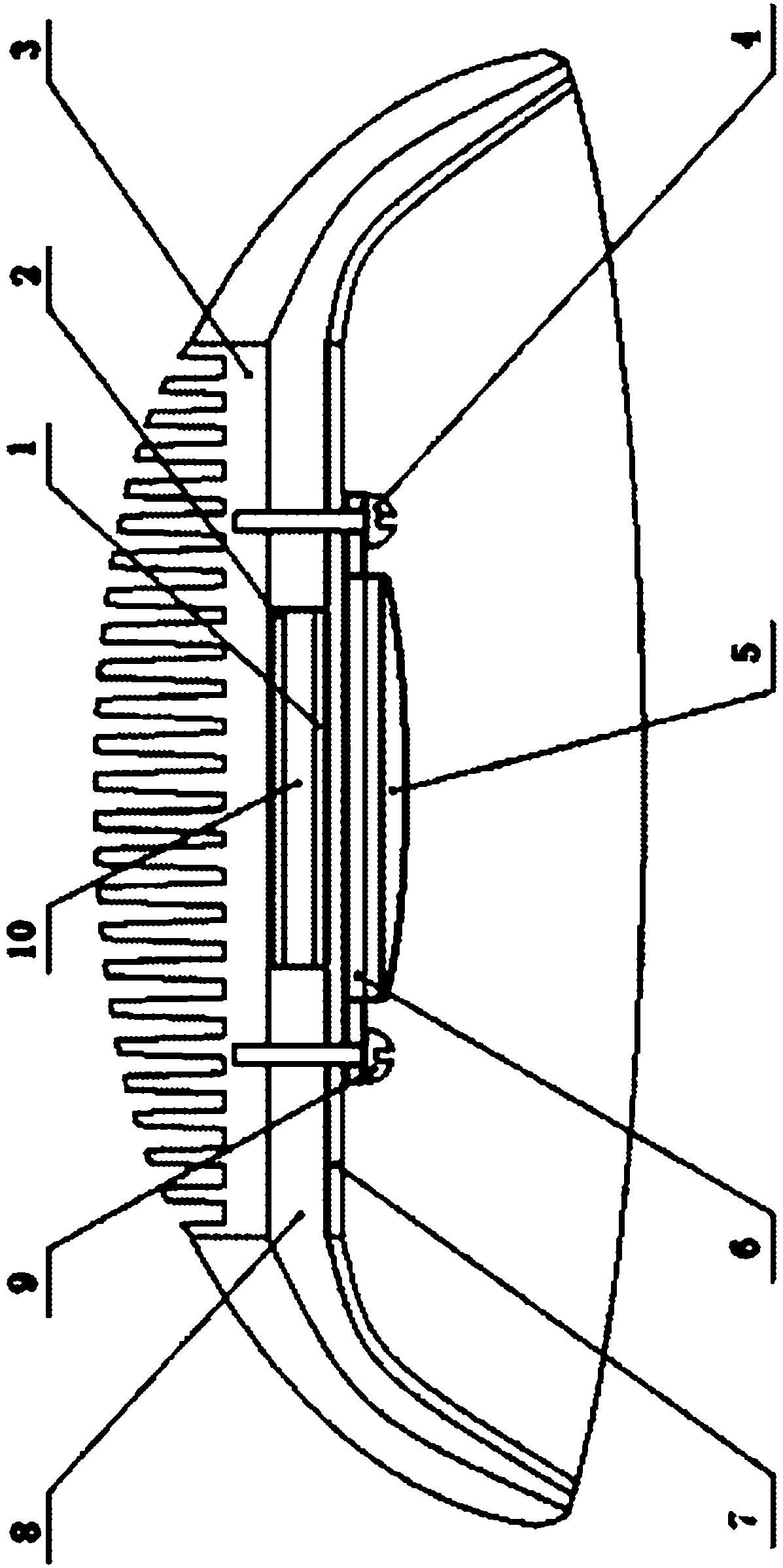

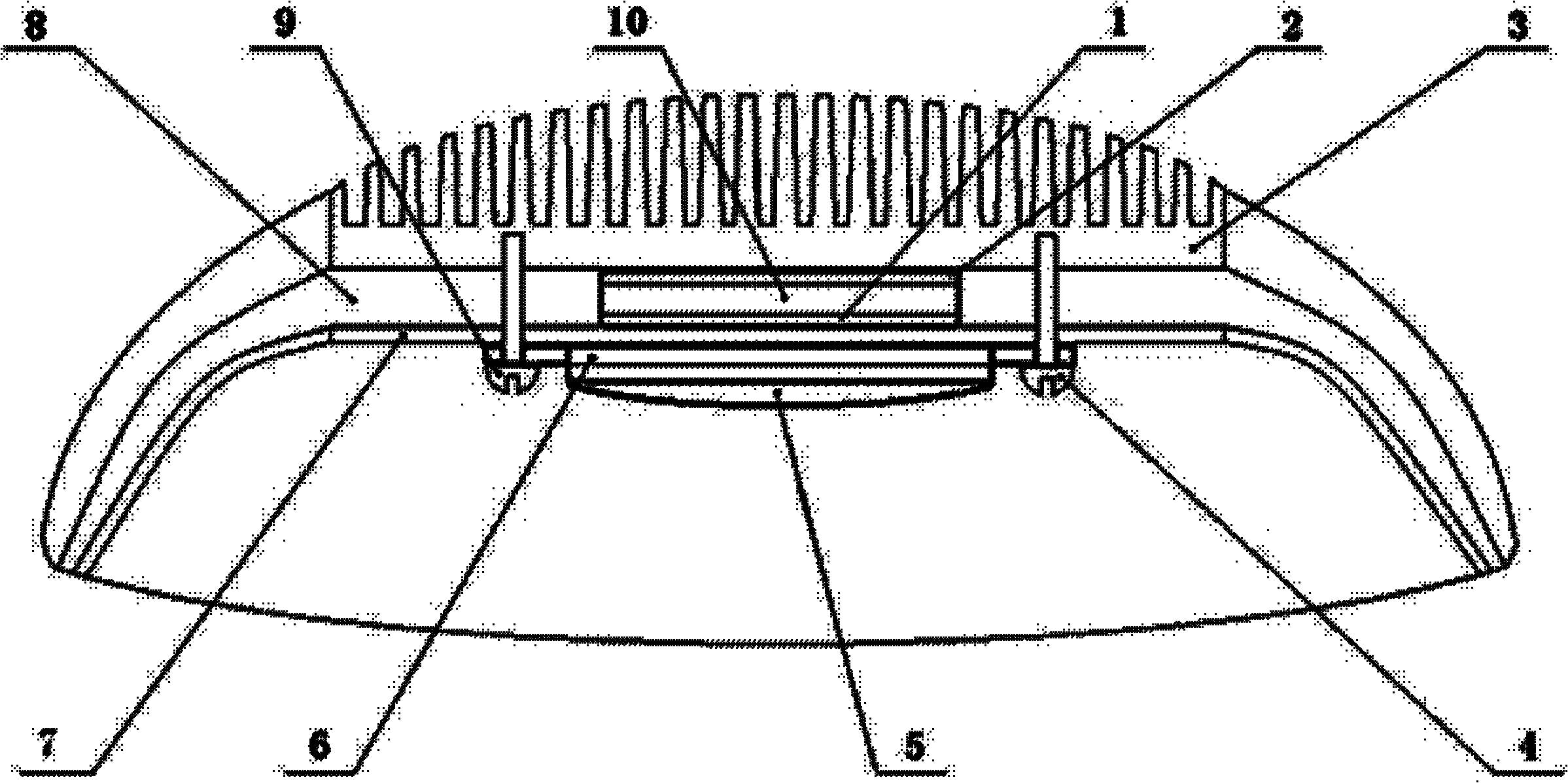

[0019] Such as figure 1 , figure 2 . The semiconductor refrigeration high-power LED lamp includes a high-power LED module 5, a cold-end metal sheet 7, a semiconductor refrigeration sheet 10, and a radiator 3.

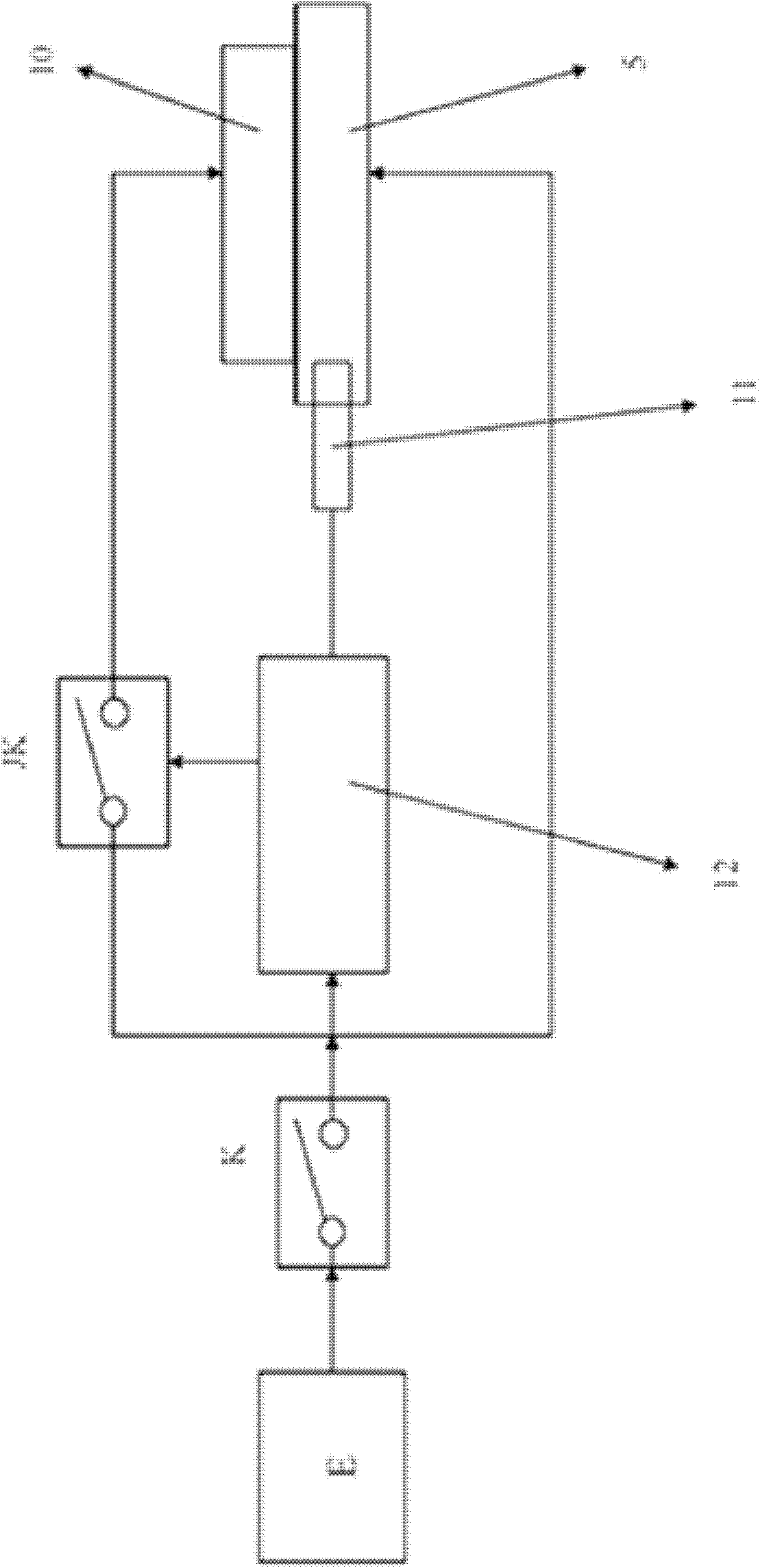

[0020] The cold end of the semiconductor cooling chip 10 is connected to the module substrate 6 of the high-power LED module 5 through the cold end metal sheet 7; a temperature sensor 11 is arranged on or near the module substrate 6, and the temperature sensor is electrically connected to an upper and lower limit temperature The control circuit 12, the temperature control switch JK electrically connected to the semiconductor refrigeration sheet is electrically connected to the upper and lower limit temperature control circuit 12, the power supply E is respectively connected to the temperature control switch JK, the upper and lower limit temperature control circuit 12 and the high-power LED module 5 through the power switch K . A plurality of insulating screws 4 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com