Single-linked low-temperature low-confining-pressure triaxial creep testing apparatus

A triaxial creep, low temperature technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of imperfect frozen soil creep test and other problems, and achieve the effect of stable air pressure, convenient movement and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

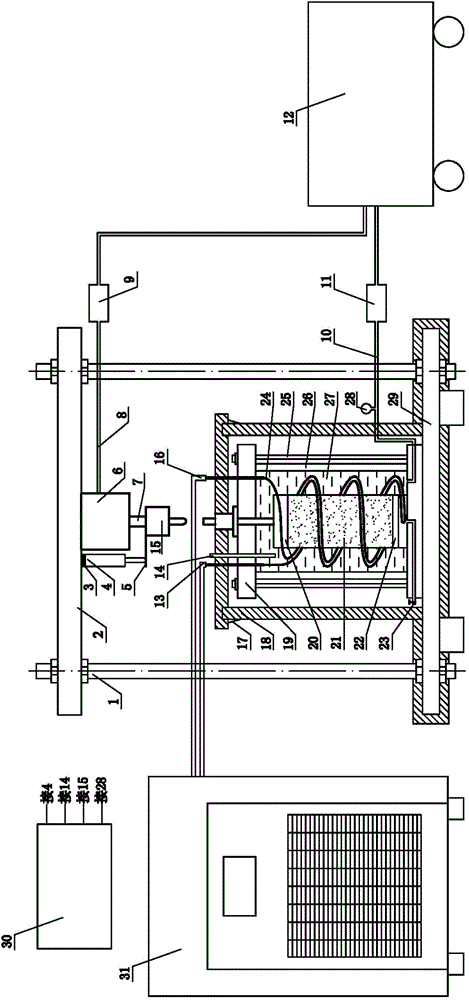

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, the creep instrument of this embodiment includes reaction force frame 2, magnetic base 3, displacement sensor 4, stainless steel plate 5, cylinder 6, cylinder dowel 7, axial pressure pipeline 8, axial pressure regulator 9, Confining pressure pipeline 10, confining pressure regulator 11, air pressure stabilization source 12, cooling bath input pipe 13, temperature sensor 14, axial load sensor 15, cooling bath output pipe 16, incubator 18, pressure chamber 19, sample cap 20 , permeable stone 22, double helix copper pipe 24, confining pressure sensor 28, base 29, automatic data acquisition system 30, automatic temperature control system 31 and two threaded rods 1, threaded rods 1 are fixed on the base 29 to adjust the reaction force The height of the frame 2, the lower part of the reaction force frame 2 is fixed with the cylinder 6, the lower part of the cylinder dowel 7 is fixed with an axial loa...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 Explain that the creep meter in this embodiment also includes an air pressure stabilization source 12 for providing axial pressure and confining pressure. Creep test under pressure. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 Note that the creep instrument in this embodiment also includes a pressure chamber 19, the inner wall of the external incubator 18 is made of rigid polyurethane insulation board, and the inner wall thickness of the incubator 8 is 80 mm. The advantage of this structure is that the thermal conductivity of rigid polyurethane material is low, and it has excellent thermal insulation performance in the current thermal insulation materials. Under the same thermal insulation requirements, the thickness of rigid polyurethane thermal insulation board can be reduced and the effective use area can be increased. Other implementation manners are the same as the specific implementation manner 1.

[0014] working principle:

[0015] Put the pressure chamber 19 and the double-helix copper tube 24 into an environment box identical to the test temperature for precooling for 2 hours, then take out the pre-cooled pressure chamber 19 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com