Gluing device for plywood processing

A technology for wood plywood and top plate, which is used in wood processing appliances, wood veneer joining, plywood presses, etc., can solve the problems of increasing the workload of the staff and inconvenient use, and achieves improving extrusion quality and reducing work. quantity, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

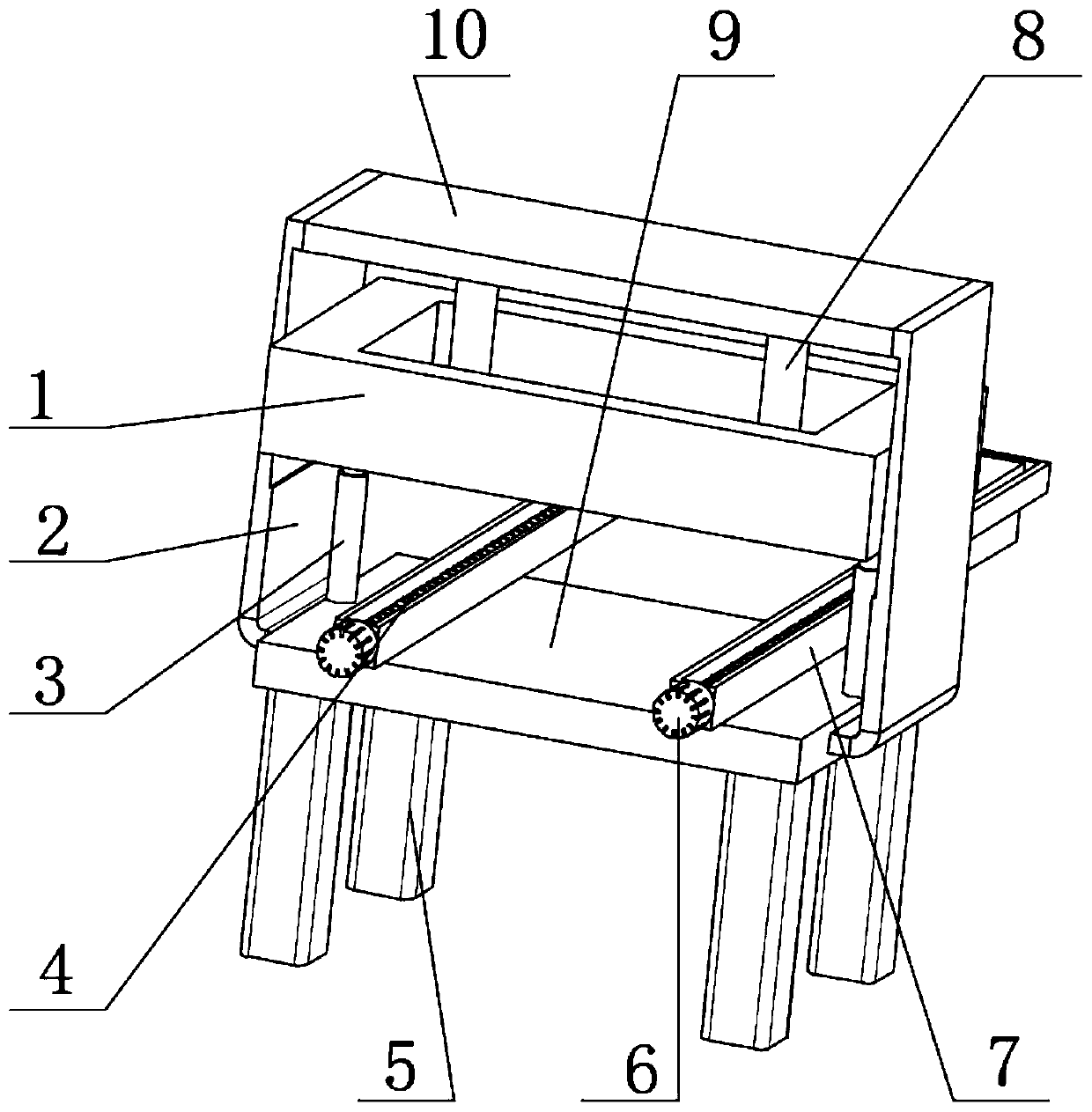

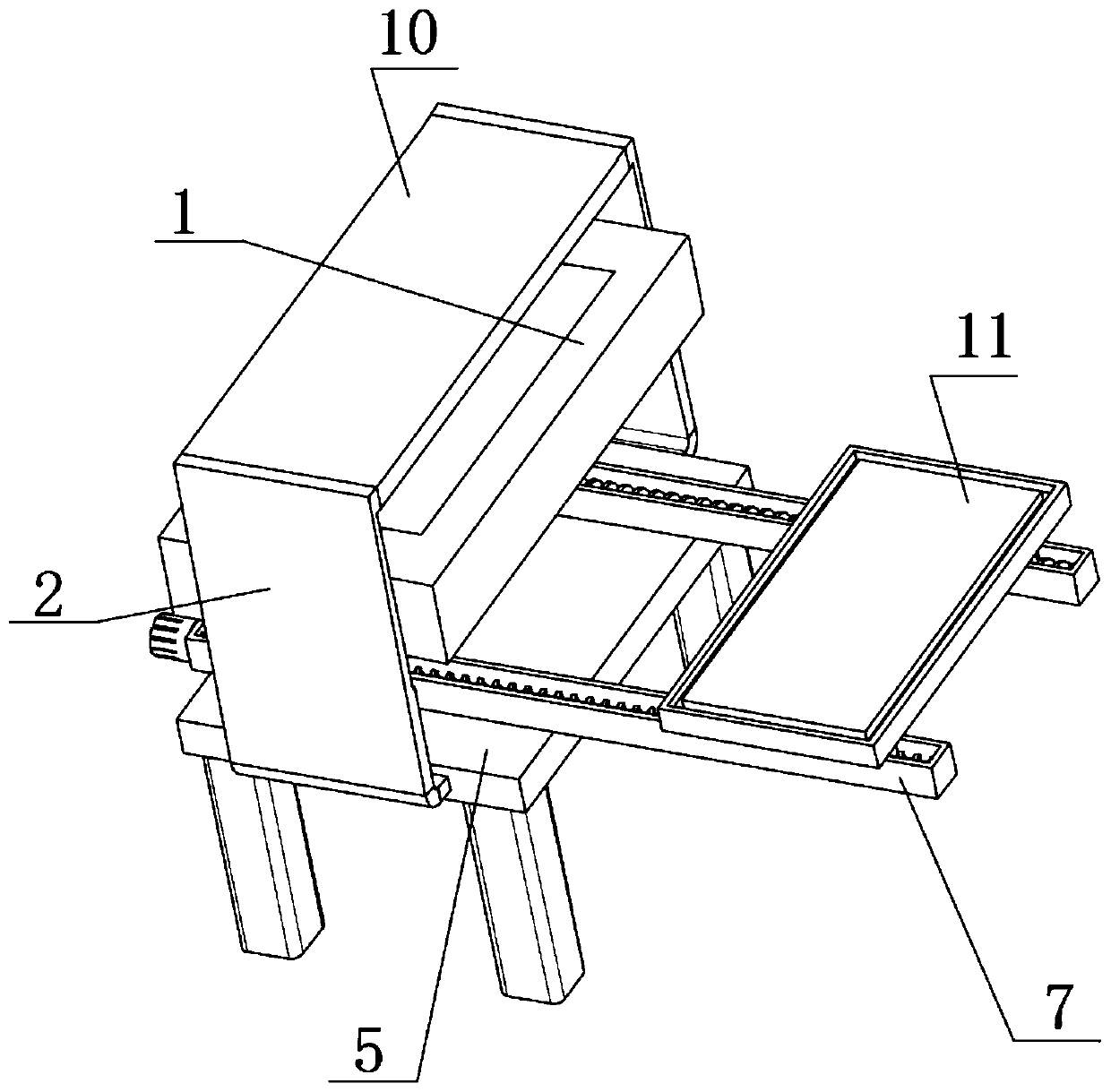

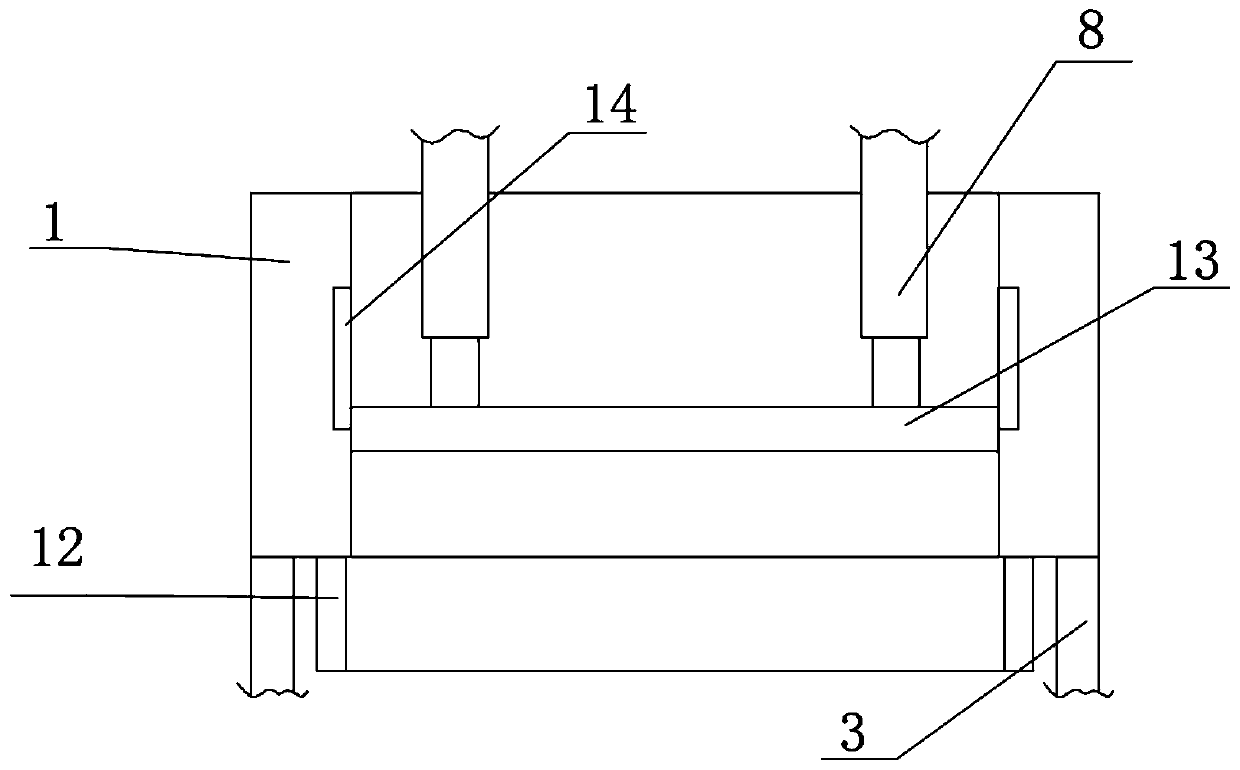

[0027] refer to Figure 1-3 , a gluing device for wood plywood processing, comprising a base 9 and four supporting legs 5, both sides of the outer wall of the top of the base 9 can be connected with supporting columns 7 by bolts, and the outer wall of the top of the supporting column 7 is provided with a rectangular groove, two rectangular grooves The inner wall of the end is rotatably connected with the same screw rod 4 placed horizontally, and the outer walls of the two screw rods 4 are rotatably connected with sliding blocks, and the top outer walls of the two sliding blocks can be connected with the same fixed plate 11 by bolts. 11 The outer wall of the top is provided with limited slots, and the four supporting legs 5 are respectively fixed to the four corners of the outer wall at the bottom of the base 9 by bolts. The outer wall at one end of the support column 7 can be connected with the motor 6 by bolts, and the output shaft of the motor 6 is connected to the outer wall...

Embodiment 2

[0031] refer to Figure 1-4 , a kind of gluing device for wood plywood processing. Compared with Embodiment 1, this embodiment also includes a sliding plate 15 slidingly connected to the inner wall of the limiting groove on the outer wall of the top of the fixed plate 11, and the outer wall of the bottom of the sliding plate 15 can be connected by bolts. Buffer spring 16, the outer wall of the bottom of buffer spring 16 is fixedly connected with the bottom inner wall of the limiting groove by bolts.

[0032] Working principle: By setting the sliding plate 15 and the buffer spring 16, the limit groove on the fixed plate 11 can be protected, preventing external debris and glue from entering the limit groove, ensuring accurate positioning, and improving the shape of the splint. quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com