Feed guide type rubber extruding machine swivel nut

A rubber extruder and screw sleeve technology, which is applied in the field of material-guided rubber extruder screw sleeves, can solve the problems of slow extruding rubber material, rising product cost, and increasing waste rate, and achieve extrusion quality and rubber output Improve the effect of "sufficient and stable food and increased production capacity"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

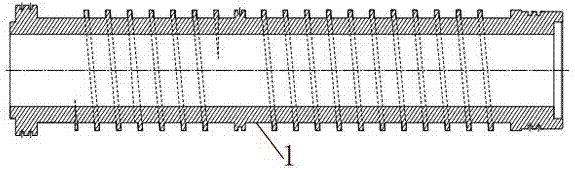

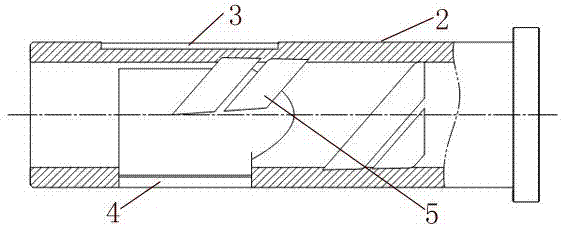

[0013] Such as Figure 1-2 As shown, a screw sleeve of a material-guiding type rubber extruder in the present invention includes a front screw sleeve 1 and a rear screw sleeve 2, both of which are movably connected to each other; the rear screw sleeve 2 is provided with a feeding port 3 and a feeding section 4. In the inner hole between the feeding port 3 and the feeding section 4, a tapered internal thread large-lead helical groove 5 is provided. The width of the large-lead helical groove 5 of the conical internal thread is 17mm-50mm, which is opposite to the direction of rotation of the external thread of the screw. Radial friction force, so that the rubber material changes from rotation to linear advancement in the feeding section as soon as possible, so that the "feeding" of the feeding port is more sufficient and stable, and the plasticization of the rubber material is more sufficient, especially when the screw speed increases. The "slipping" phenomenon of rubber materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com