Die heating device of tyre rubber extruding machine

A technology of heating device and die shape, which is applied in the field of tire processing machinery, can solve the problems of uniform preheating to reach the ideal temperature, no die heating equipment, thicker and larger die plate, etc., to achieve simple structure and low cost , the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

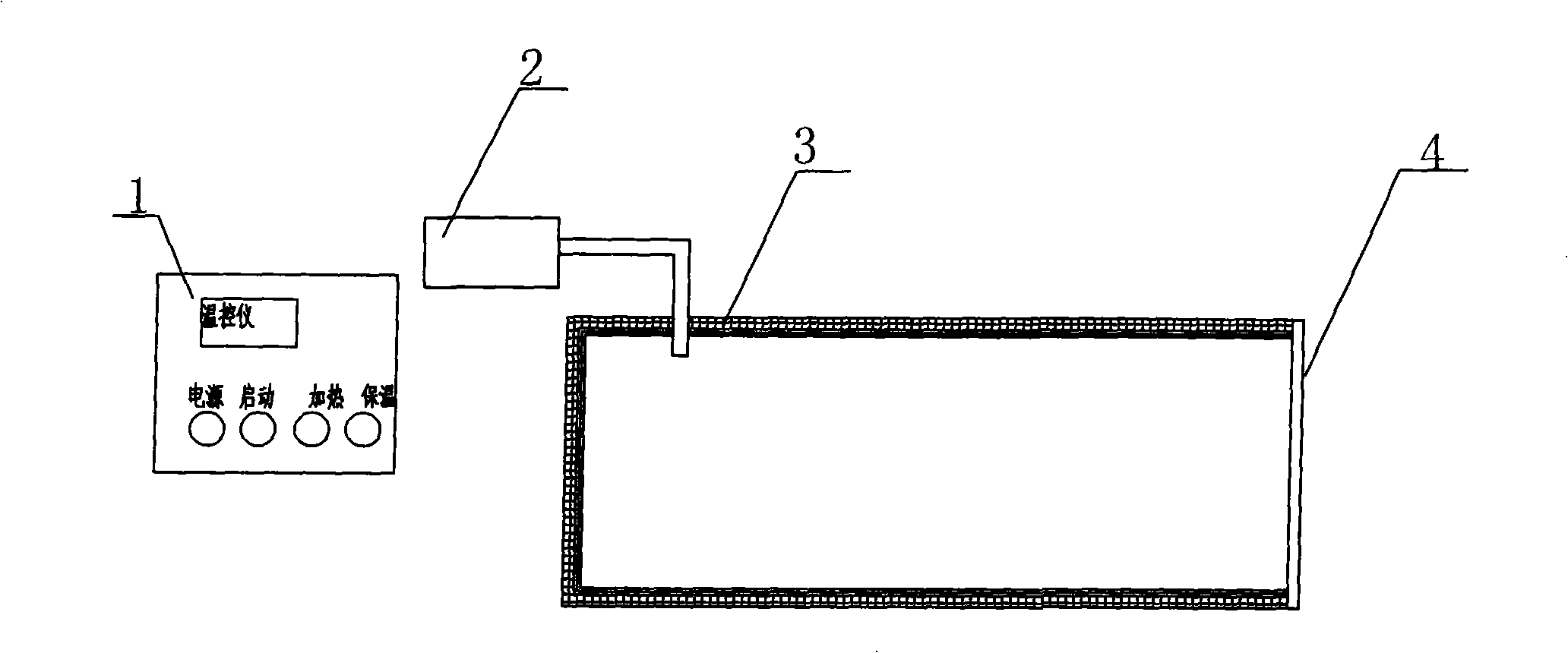

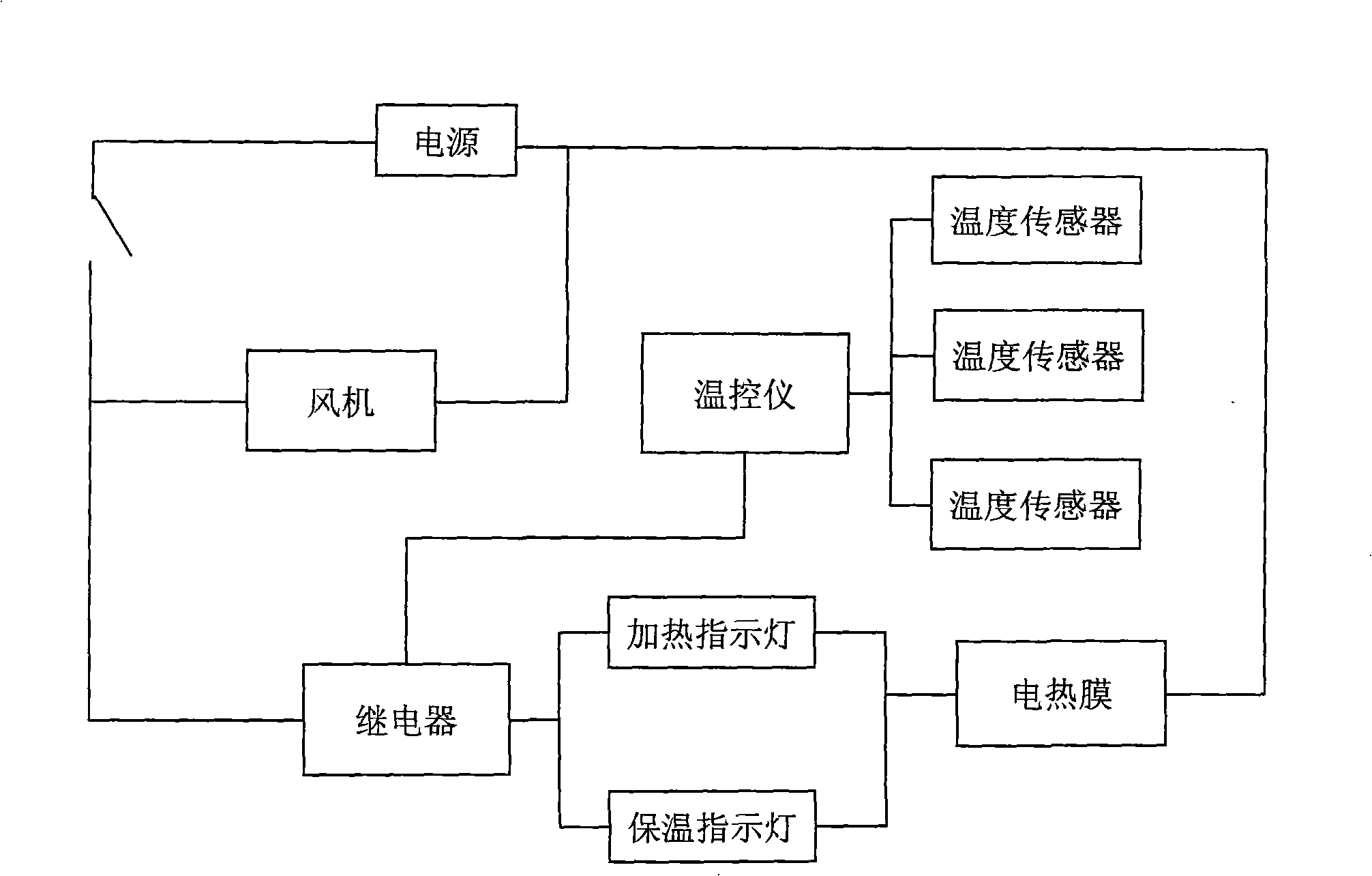

[0013] Example of the die heating device of the tire rubber extruder figure 1 As shown, it includes a box body 3 and a temperature controller. One end of the box body 3 is a box door 4 that can be opened and closed, and the mouth shape is put in or taken out from the box door 4 . The wall of the box is a composite layer board structure, and an insulating and thermal insulation layer is sandwiched between the inner surface layer board and the outer layer board. Insulation insulation layer. The temperature controller includes a temperature controller and a relay installed in the operation box 1 and three temperature sensors installed in the box 3 . like figure 2 As shown, the electric heating film is connected to the relay in the operation box 1 . The signal line of the temperature sensor is led out from the box 3 and connected to the signal terminal of the temperature controller. The control terminal of the temperature controller is connected to the relay. The operation box...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com