Kitchen waste resource utilization biological treatment method

A technology for biological treatment and kitchen waste, applied in chemical instruments and methods, solid waste removal, solid separation, etc., can solve problems affecting granulation efficiency and granulation quality, improve efficiency and granulation quality, and avoid crowding Roller wear and the effect of reducing roller dandruff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a biological treatment method for resource utilization of kitchen waste. The biological treatment method includes the following steps:

[0055] S1. Unloading and sorting the food waste to obtain materials to be processed.

[0056] S2. Crushing the material to be processed, and extruding and dehydrating the crushed product.

[0057] S3, performing microbial treatment on the product after extrusion dehydration, and drying the product after microbial treatment.

[0058] S4. Grinding the dried product.

[0059] S5, granulating the pulverized product.

[0060] Wherein, in step S5, a granulation equipment is used to granulate the pulverized product.

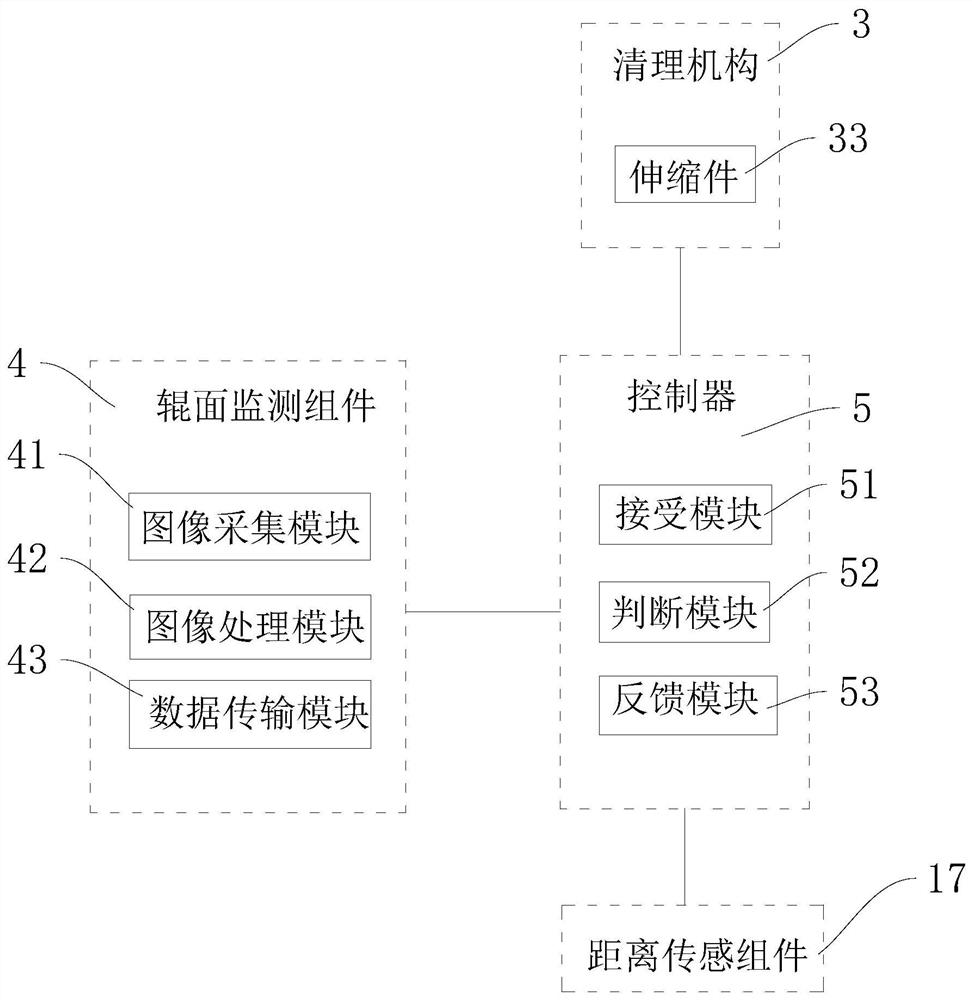

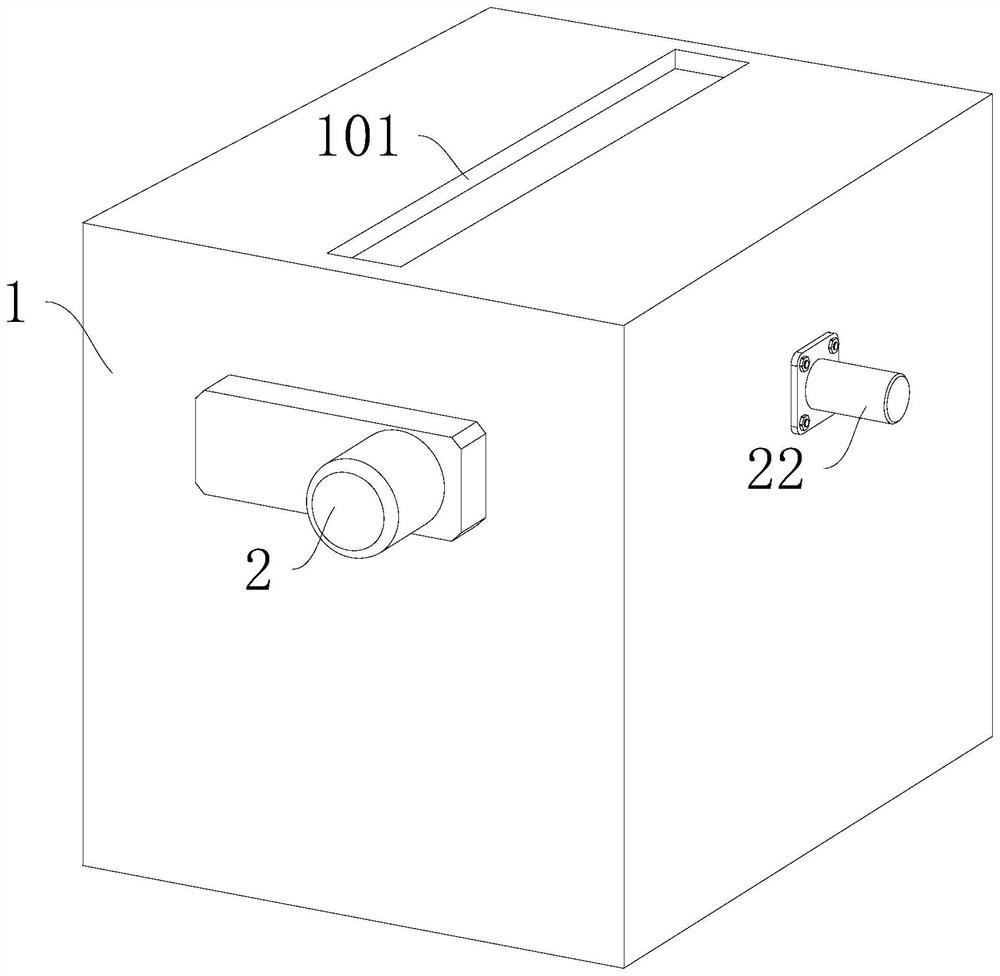

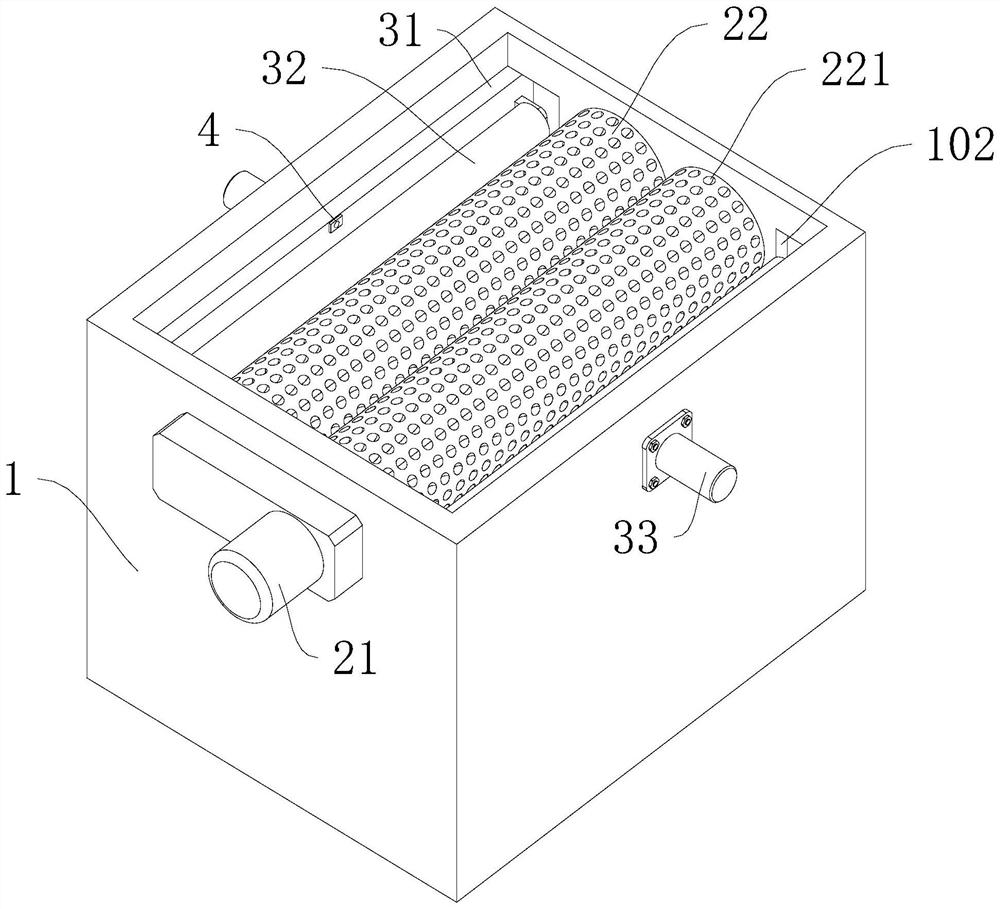

[0061] see figure 1 , figure 2 As shown, the granulation equipment includes: a granulation box 1 , an extrusion mechanism 2 , a cleaning mechanism 3 , a roll surface monitoring component 4 and a controller 5 .

[0062] A material inlet 101 is provided on the top of the granulation box 1 . In this...

Embodiment 2

[0085] see Figure 5 , this embodiment provides a biological treatment method for resource utilization of kitchen waste. In this embodiment, on the basis of Embodiment 1, the granulation equipment may further include a feeding mechanism 6 .

[0086] Please combine Figure 6 and Figure 7 , The feeding mechanism 6 is arranged on the top of the granulation box 1 . The feeding mechanism 6 includes a feeding hopper 61 and a leveling assembly 62 . The inside of the feeding hopper 61 communicates with the feeding port 101 . The screed component 62 is arranged above the material inlet 101 . The screed assembly 62 includes a screed rod 621 , multiple claws 622 , and a driving motor 623 . The driving motor 623 is arranged on the hopper 61 . One end of the screed rod 621 is fixedly connected with the output shaft of the driving motor 623 . In this embodiment, the driving motor 623 may be a stepping motor, and the controller 5 controls the output end of the driving motor 623 to r...

Embodiment 3

[0090] see Figure 8 and Figure 9 , this embodiment provides a biological treatment method for resource utilization of kitchen waste. In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the granulation equipment may further include a collection box one 8 , a collection box two 9 , and a material guide plate 10 .

[0091] Collection box one 8 is positioned at the below of extruding mechanism 2 material falling points, and collection box can be installed in the granulation box 1 movably, thereby can be convenient to collection box can be taken out from granulation box 1 inside when collection box is stored full.

[0092]Both sides of the granulation box 1 can be provided with an opening 103 respectively. Two material guide plates 10 can be provided, both of which are arranged in the granulation box 1 . One end of each material guide plate 10 is a material receiving end, and the other end is a material discharging end. The material receiving end of each materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com