3D ceramic printing device drying by virtue of heating fan

A heating fan and printing device technology, applied in the field of 3D printing, can solve problems such as inability to reinforce ceramic parts, change of moisture content in local structures, collapse of ceramic structures, etc., achieve light weight, improve extrusion molding quality, and increase stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

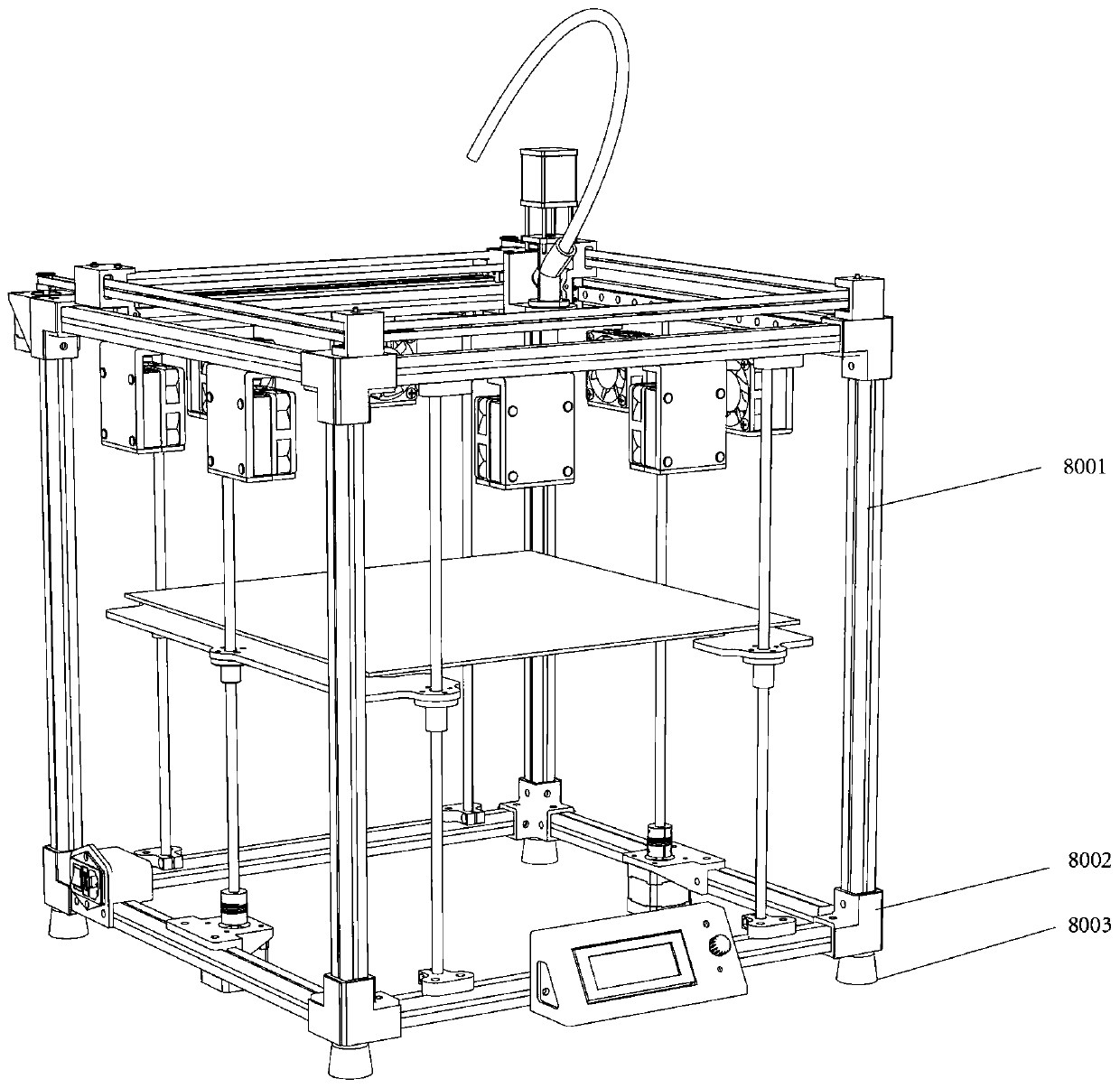

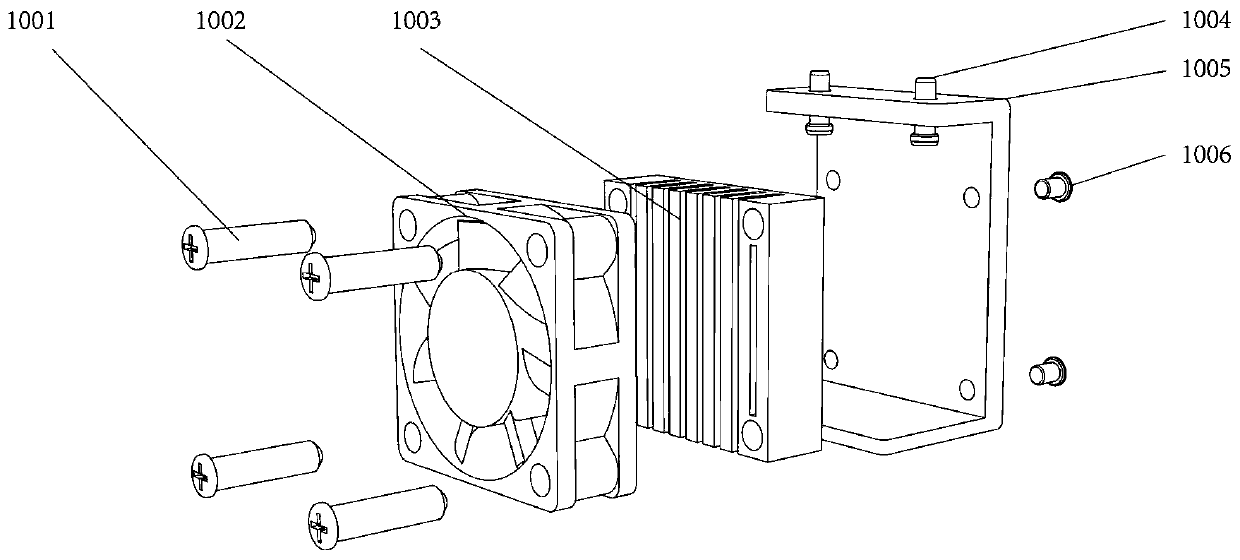

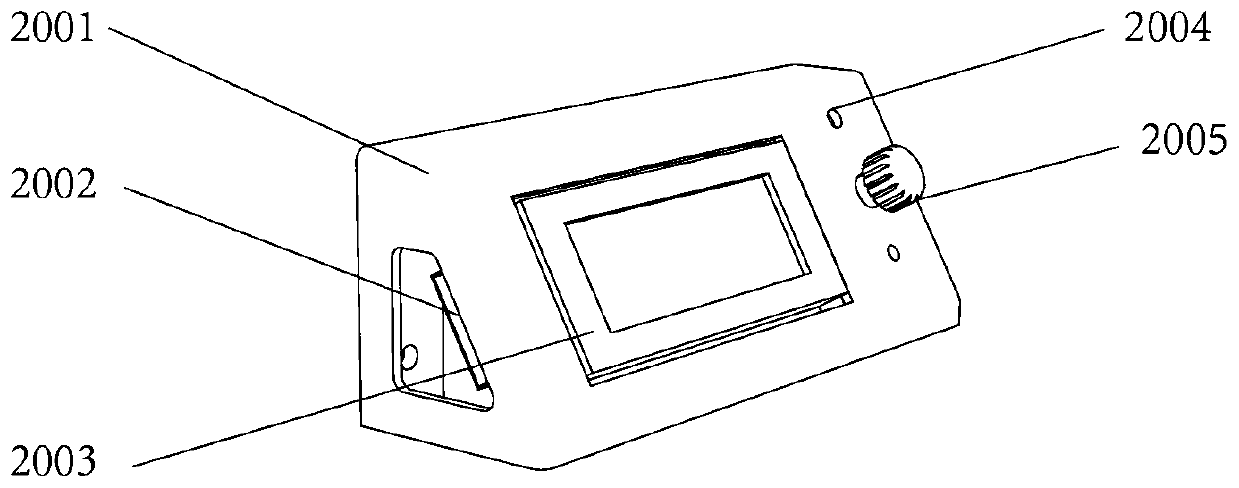

[0032] The present invention relates to a ceramic 3D printing device that uses a heating fan to dry. The preferred embodiments of the present invention will be further described in detail below. For the convenience of description, in this technical solution, the definition figure 1 The end where the operating device is located is the front and the lower end, the power supply system is on the side, and the position where the ceramic printing device is located is the upper end, and it is stipulated that the beam where the operating device is located is along the X-axis direction, and the height direction of the 3D printing device is the Z-axis direction. The direction perpendicular to the Z axis is the Y axis direction.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com