Experimental machine for testing extrusion properties of rubber

A technology for testing experiments and performance, applied in the field of experimental equipment, can solve problems such as frequent temperature control, achieve the effects of saving power, significant economic benefits, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

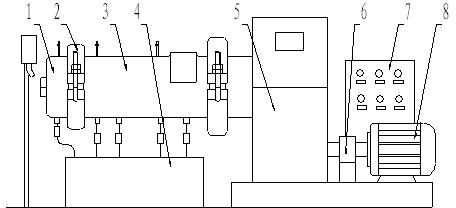

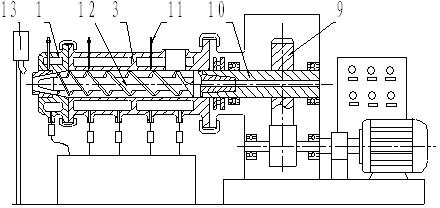

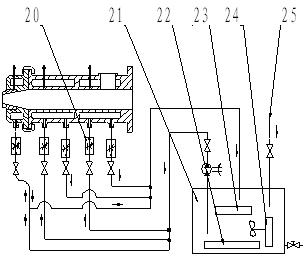

[0035] The main principle of the rubber extrusion performance testing experimental machine of the present invention is;

[0036] ① Under the condition that a specific experimental testing condition remains unchanged, test and compare other required data parameters to obtain accurate and practical data results. The present invention is to use a set of power transmission device (motor, reduction box), equipped with screws with different thread structures, combined with advanced detection and control technology, to carry out extrusion performance test experiments on rubber compounds with various formulas.

[0037] ②Through the multivariate and multivariate comparison test experiments on the extrusion properties of various rubber compounds, it is possible to understand and grasp the extrusion properties of the compounds qualitatively and quantitatively, and to make accurate data collection. It is conducive to quick and simple application to the industrial production of enterprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com