Perpendicular stretching method and equipment for optical fiber perform

An optical fiber preform and drawing equipment technology, which is applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problems of uneven heating of the mother rod, increase in production cost, and the influence of size, roundness and bow curvature control, etc. The effect of drawing control accuracy, improving drawing efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

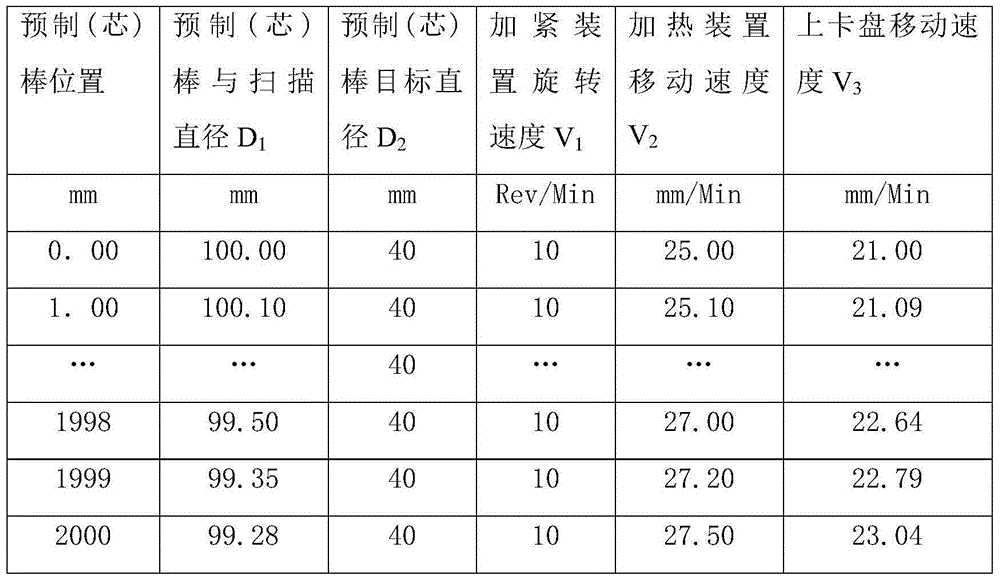

[0029] The implementation object of the present invention is a large-diameter optical fiber preform, including a solid-core optical fiber preform, or a core rod, or a combination of a glass sleeve and a core rod. The implementation process is to stretch the large-diameter optical fiber preform into a small-diameter optical fiber preform, the outer diameter of the large-diameter optical fiber preform is between 20 and 200 mm; the outer diameter of the small-diameter optical fiber preform is between 10 and 200 mm. Between 120mm.

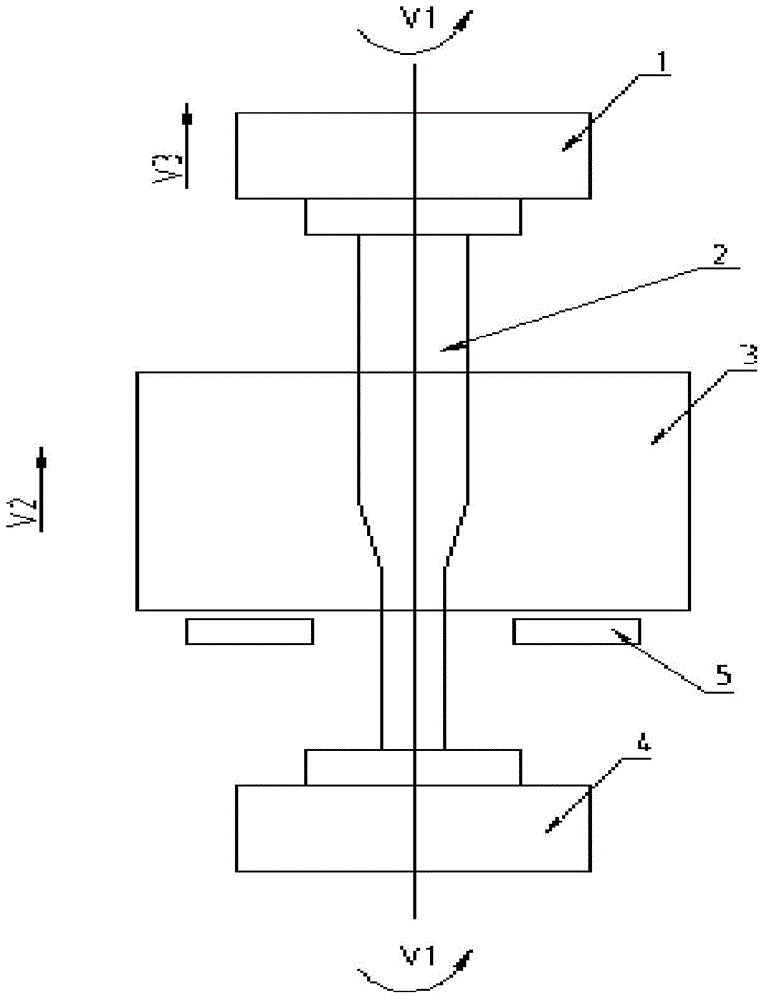

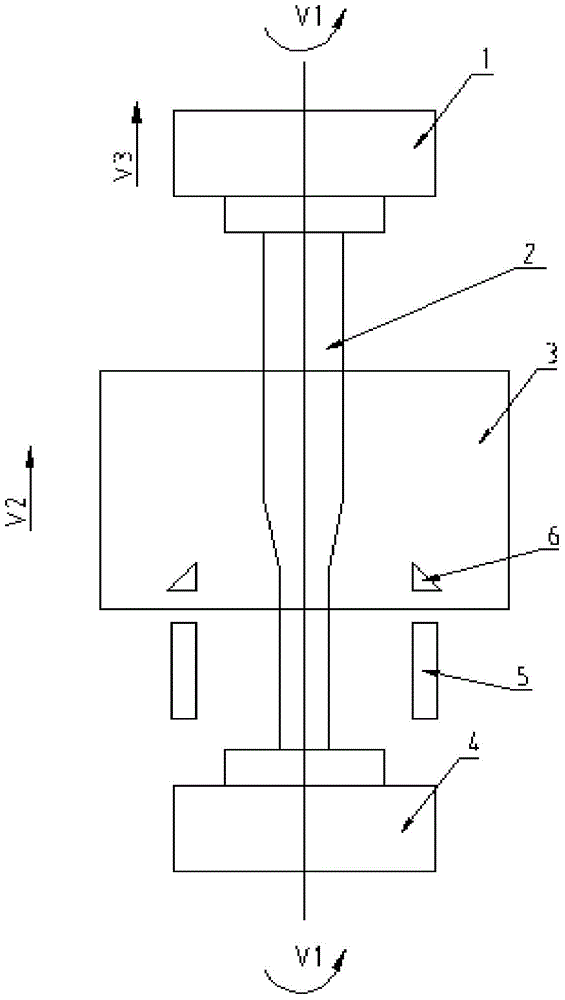

[0030] A vertical stretching device for an optical fiber preform involved in the implementation of the present invention includes an upper clamping device 1, a lower clamping device 4, and a control system. A vacuum system is arranged above the upper clamping device 1. A heating device 3 is installed between the upper and lower clamping devices and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com