Cable straightening device for communication engineering

A communication engineering and cable technology, which is applied in the field of cable straightening equipment, can solve the problems such as the large size of the cable straightening equipment, which is inapplicable and troublesome, and achieves the effect of small overall structure and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

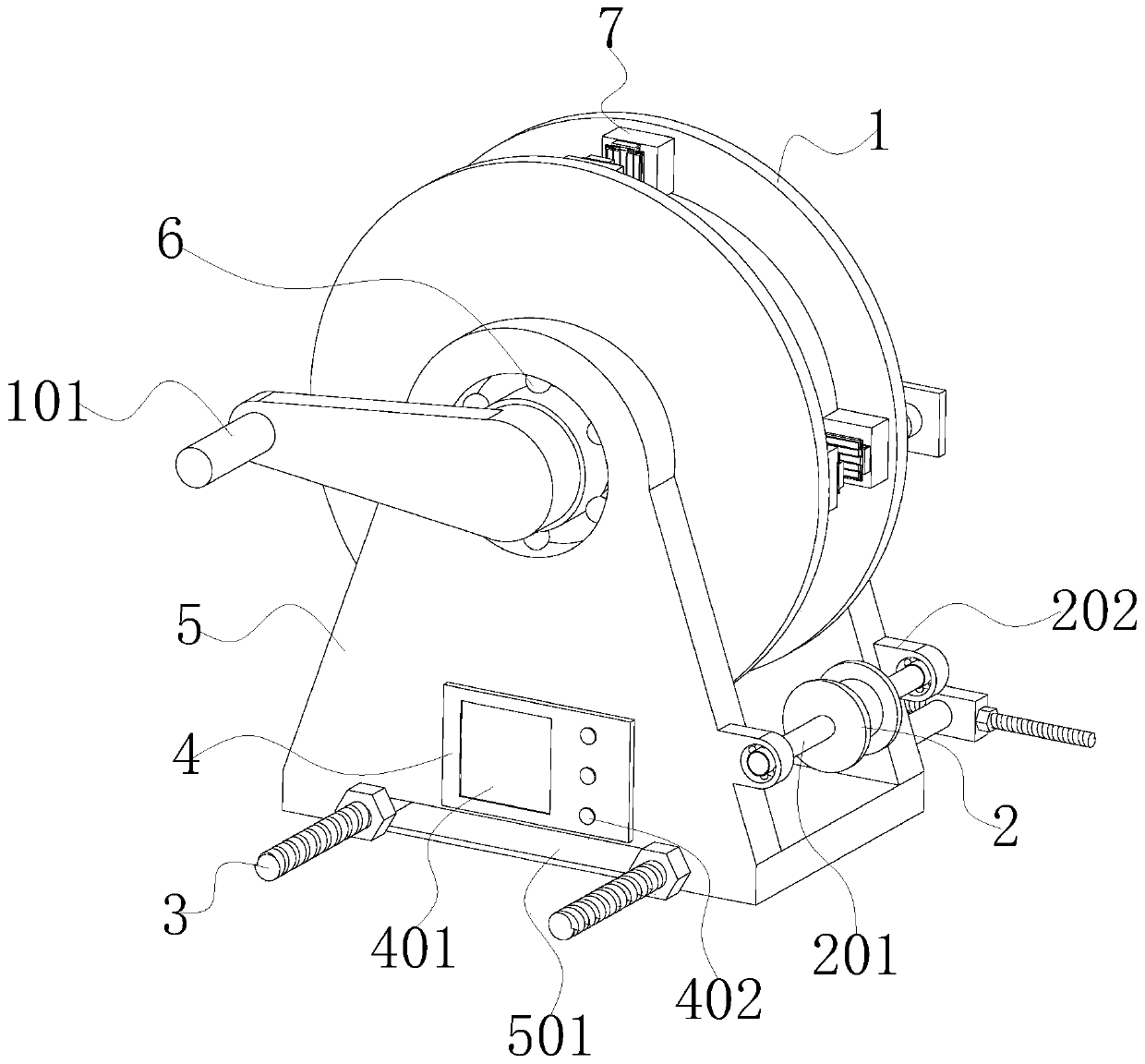

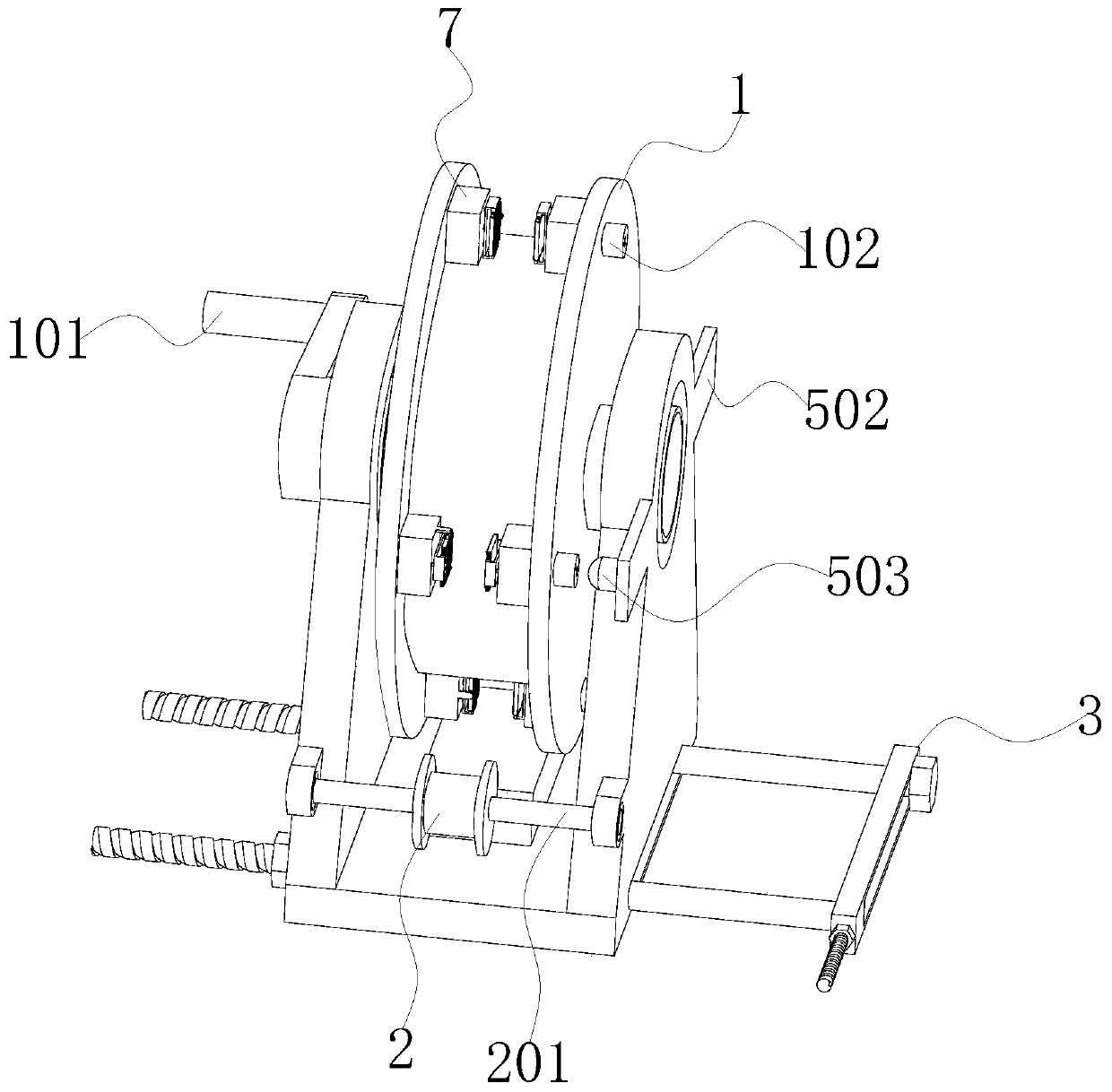

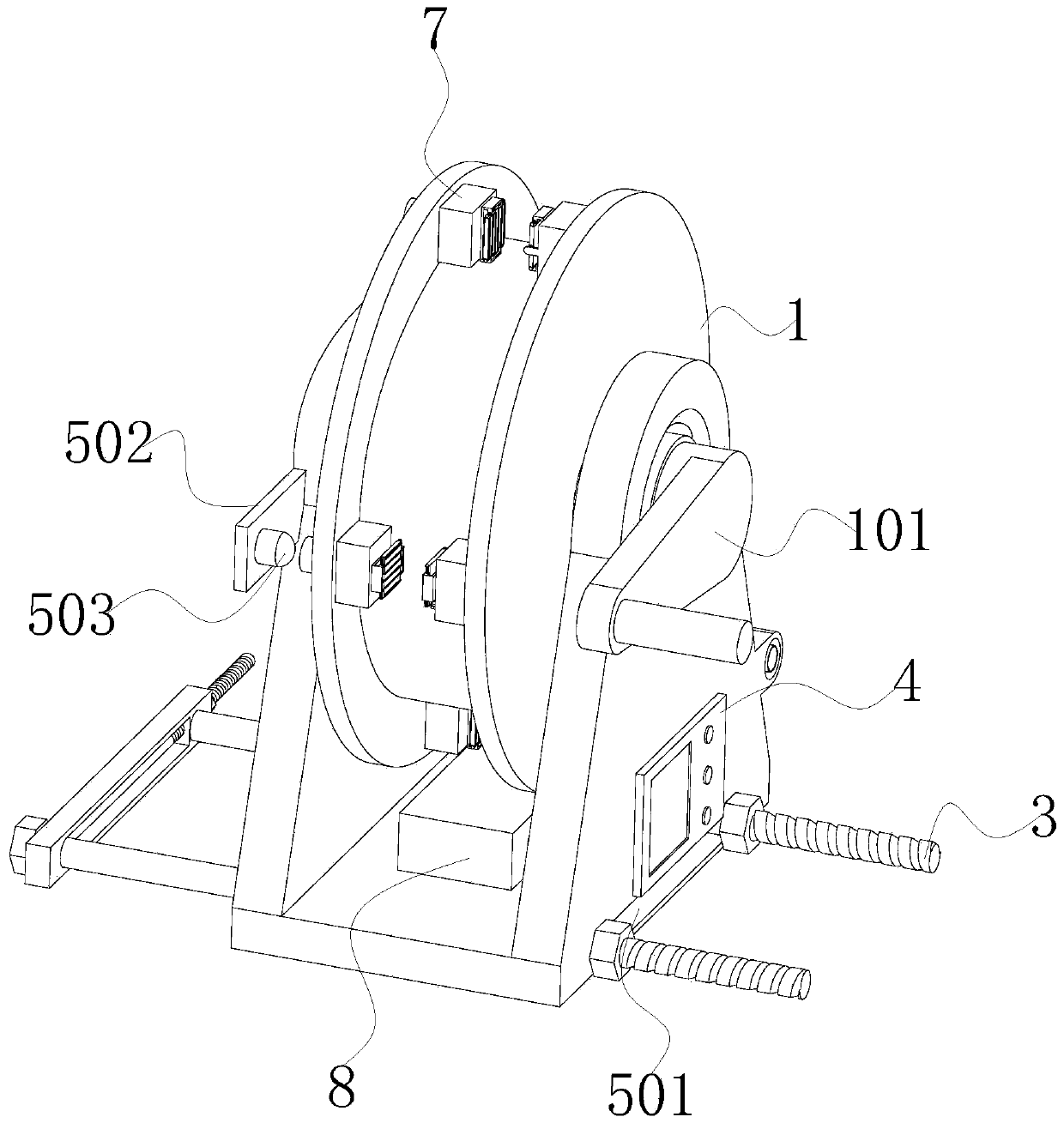

[0037] see Figure 1-5 As shown, the present invention is a cable straightening device used in communication engineering, including a rotating roller 1, a base 5 and a clamping mechanism 7, the inner upper end of the base 5 is provided with a rotating roller 1, and two rotating rollers 1 are opposite to each other. There are four groups of clamping mechanisms 7 uniformly distributed along the circumferential direction on the inner surface of the inner surface, and each group of clamping mechanisms 7 is composed of two opposite clamping mechanisms 7, and the two clamping mechanisms 7 in each group cooperate with each other. The cable can be clamped under;

[0038] The center position of the rotating roller 1 is fixedly fitted with a rotating shaft 103, and the two ends of the rotating shaft 103 are respectively connected to the base 5 through rolling bearings 6. The end of the rotating shaft 103 farther away from the infrared emitter 503 is fixedly connected with a rotating han...

Embodiment 2

[0059] Based on the heating assembly described in the first embodiment, the rotating roller 1 is covered with a rope, which can realize the use of the device from the upper end of the communication pole transported from the lower end of the communication pole.

[0060] In addition, in order to improve the fixing stability of the device, the friction coefficient between the device and the communication rod can be improved by setting the damping material pad on the opposite side of the limiting strip 302 described in the first embodiment and the base 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com