Heat preservation heating device used in culvert low-temperature environment and using method

A low-temperature environment and heating device technology, applied in mining equipment, underground chambers, shaft equipment, etc., can solve problems such as the quality of culverts not meeting the design requirements, the strength not meeting the requirements, and the existence of potential safety hazards. , good quality, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

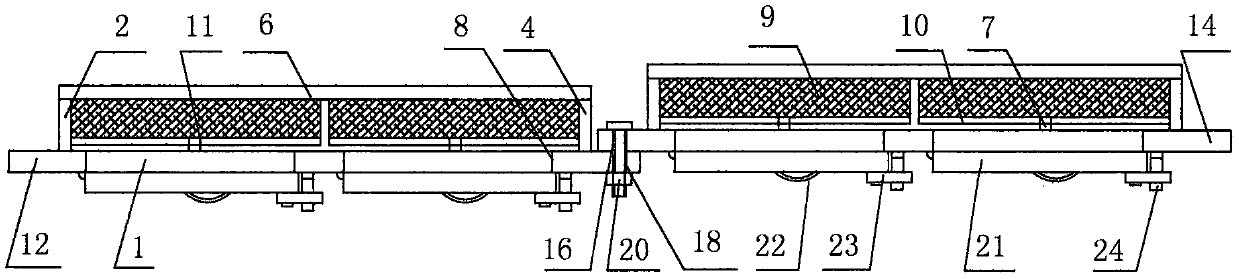

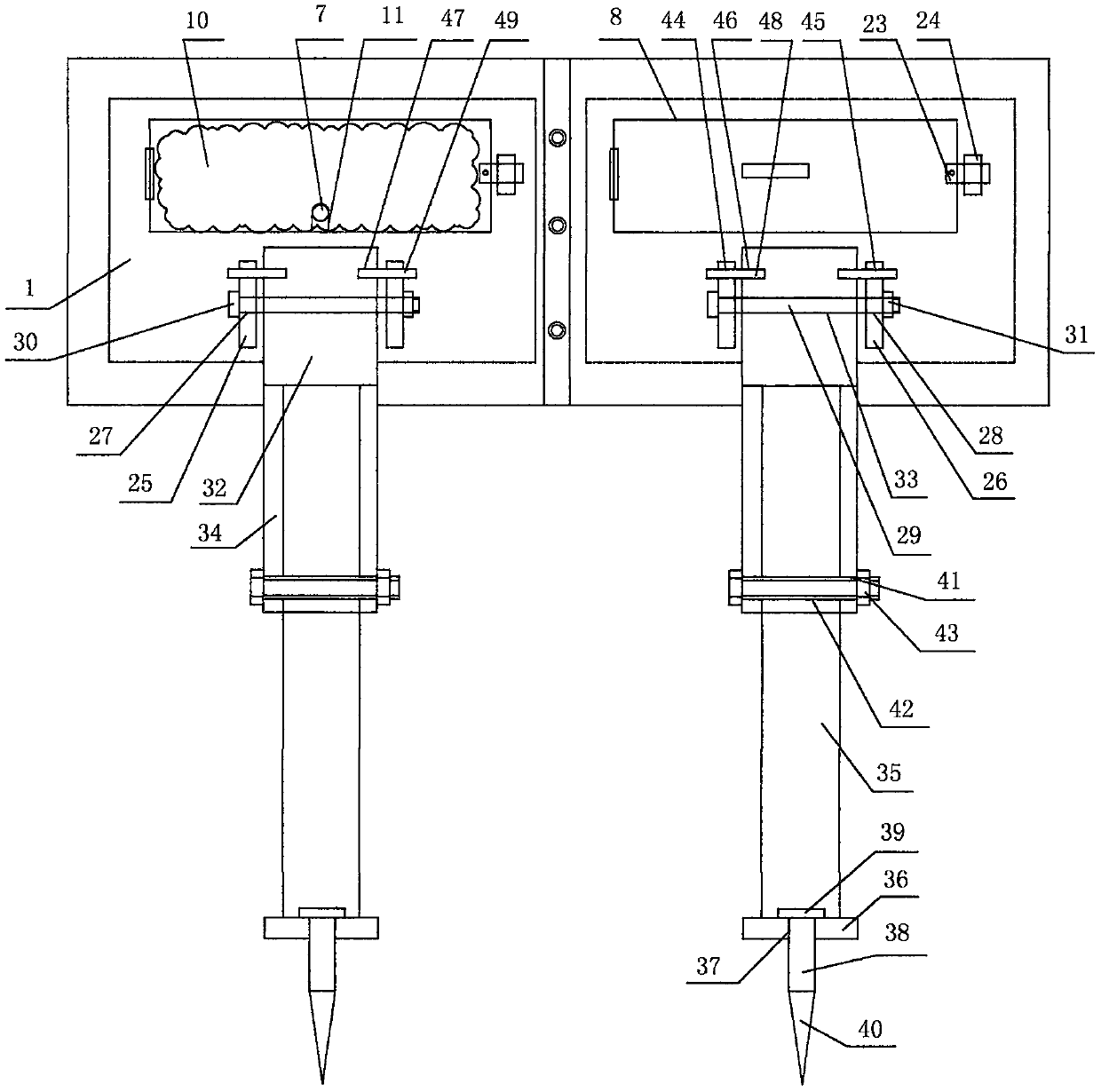

[0029] A heat preservation and heating device used in a low-temperature environment in a culvert, the composition of which includes: an inner arc plate 1, and the inner arc plate is sequentially connected to a left wall plate 2, an upper wall plate 3, a right wall plate 4, and a lower wall plate 5, The left wall, the upper wall, the right wall, and the lower wall are connected by a steel mesh 6, and the steel mesh is fixedly connected to a set of support rods 7, and the The support rods are arranged horizontally and then vertically. The inner arc plate is provided with a set of material openings 8. The charging openings are arranged horizontally and then vertically. The inner arc plate and the steel mesh There is a hot post 9 between them, the hot post is bonded to the hard strip 10, and the bottom of the hard strip is provided with an inverted U-shaped bayonet 11, and the inverted U-shaped bayonet is snapped into the The support rod described above is fixed.

[0030] The lef...

Embodiment 2

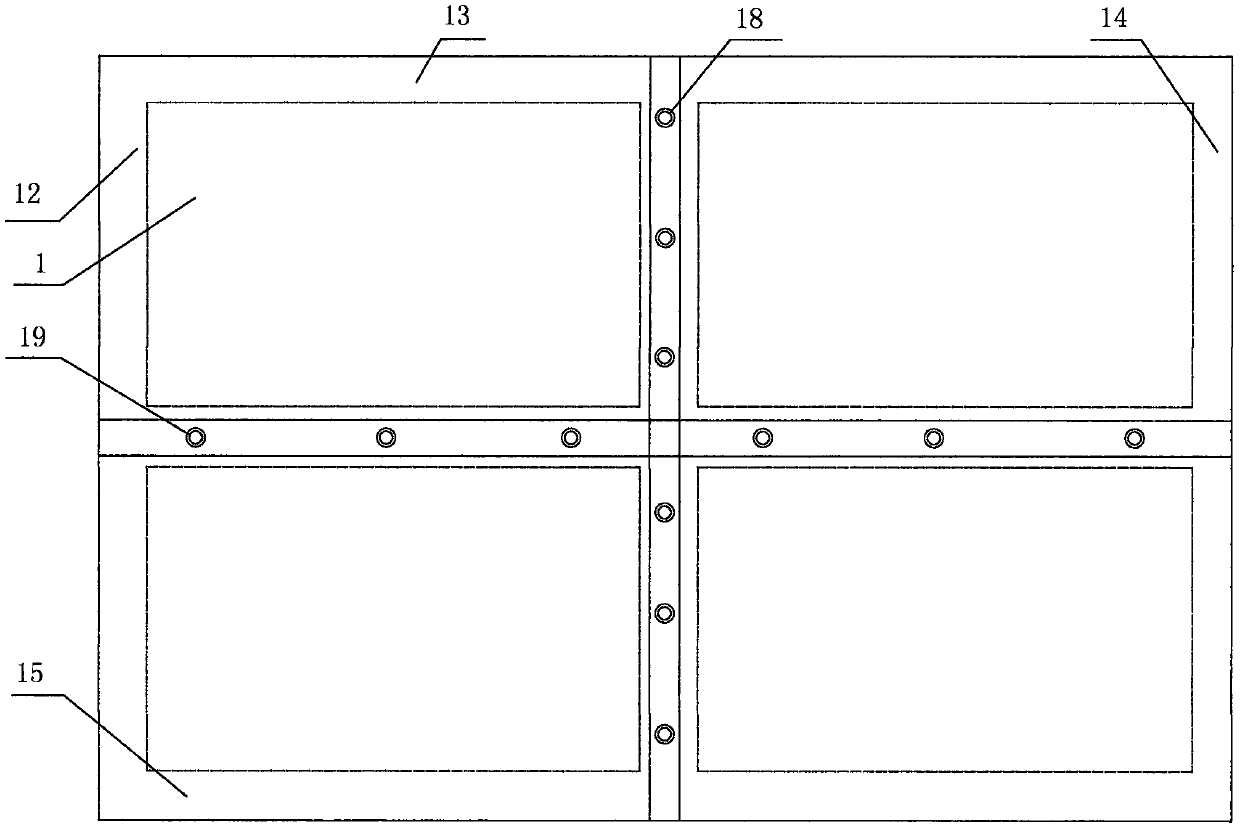

[0033] In the heat preservation and heating device used in the low temperature environment of a culvert described in Example 1, there is a left outer edge plate 12 between the inner arc plate and the left wall plate, and the inner arc plate and the upper wall There is an upper outer edge plate 13 between the plates, a right outer edge plate 14 between the inner arc plate and the right wall plate, and a lower outer edge plate between the inner arc plate and the lower wall plate. Along the plate 15, the left outer edge plate has a set of left fixing holes 16, the upper outer edge plate has a set of upper fixing holes 17, and the right outer edge plate has a set of right fixing holes 18. Said lower outer edge plate has a group of lower fixing holes 19.

[0034] The outer edge plate makes the assembly between the inner arc plates convenient and fast. After the inner arc plates are connected, it is firm and stable, and can fix the thermal paste well, and the heating effect for the ...

Embodiment 3

[0036] In the heat preservation and heating device used in the low-temperature environment of a culvert described in Example 2, when the left and right sides of the inner arc plates are overlapped and connected, the left outer edge plate and the right outer edge plate are superimposed, and the The left fixing hole and the right fixing hole coincide and are fixed by bolts 20. When the upper and lower parts of the inner arc plate are overlapped and connected, the upper outer edge plate and the lower outer edge plate are superimposed, and the The upper fixing hole is overlapped with the lower fixing hole and fixed by bolts.

[0037] The inner arc plates fixed by bolts are firm and stable, safe to use and effective to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com