Magnesium alloy casting method and device thereof

A magnesium alloy and mixed gas technology, which is applied in the field of casting, can solve the problems of magnesium alloys being easy to burn, and achieve the effects of good performance, convenient operation, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

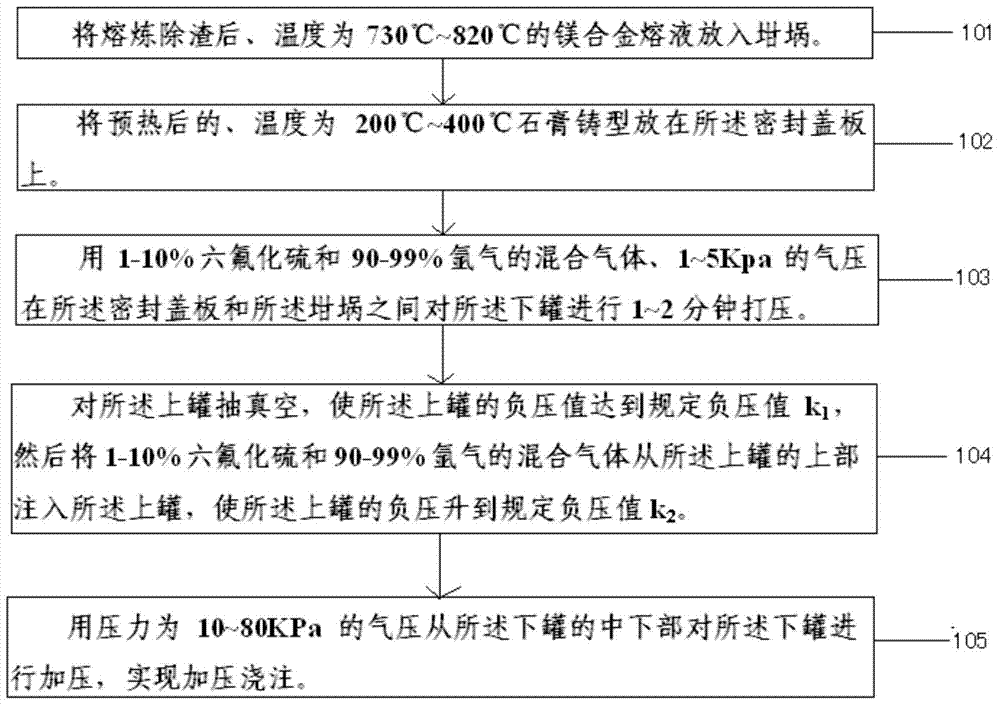

[0040] like figure 1 As shown, this embodiment describes a casting method for magnesium alloy near pressure regulating gas protection, the method includes the following steps:

[0041] Step 101. Put the molten magnesium alloy at a temperature of 730° C. to 820° C. after smelting and deslagging into a crucible. The crucible is built into a lower tank, and the lower tank is sealed with a sealing cover.

[0042] On the one hand, due to the high pouring temperature of magnesium alloy thin-walled parts, the magnesium alloy melt and gypsum are prone to react; The reaction between liquid and gypsum, therefore, after many tests, the melting temperature of the magnesium alloy in this embodiment is 730°C-820°C.

[0043] Step 102: Put the preheated plaster mold at a temperature of 200° C. to 400° C. on the sealing cover plate, and cover the lower jar with the upper jar.

[0044] In order to prevent the temperature of the gypsum mold from being too low and reduce the temperature of the ...

Embodiment 2

[0064] The following ZM10 magnesium alloy, gypsum-type ingredients (mass fraction) are: 15% to 20% of quartz powder, 6% to 8% of talc powder, 60% to 85% of α hemihydrate gypsum, 18% to 25% of MgS0 4 , water and other materials, the mixed gas ratio is 10% sulfur hexafluoride and 90% argon as raw materials, combined Figure 4 The casting device structural diagram shown, specifically introduces this embodiment, as figure 2 As shown, the specific steps of a casting method of a magnesium alloy near pressure regulating gas protection described in this embodiment are as follows:

[0065] In step 201, the ZM10 magnesium alloy is smelted at 780° C., and the slag is removed, and the slag-removed magnesium alloy melt is put into a crucible, and the lower tank is sealed with a sealing partition.

[0066] Step 202, preheating the gypsum mold at 380°C, closing the tank and putting the upper tank cover on and off the tank.

[0067] Step 203, pressurizing the lower tank for 1 minute with ...

Embodiment 3

[0073] The casting method of a magnesium alloy close to the pressure regulating gas protection described in this embodiment is basically the same as the technical solution described in the above-mentioned preferred embodiment, except that the raw materials and process parameters are different:

[0074] 1. The raw materials are different, the magnesium alloy is ZM5, and the mixed gas ratio is 5% sulfur hexafluoride + 95% argon;

[0075] 2. The temperature of the magnesium alloy ZM5 melt is 820°C, and the preheating temperature of the gypsum type is 400°C;

[0076] 3. Vacuumize the upper tank to make the negative pressure of the upper tank reach -20KPa, and then inject the mixed gas into the upper tank to raise the negative pressure of the upper tank to -10KPa;

[0077] 4. Pressurize the lower tank for 2 minutes with a mixed gas of 5% sulfur hexafluoride and 95% argon at a pressure of 3Kpa

[0078] 5. Use the air pressure of 55KPa to pressure pour the lower tank, the liquid lifti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drag coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com