Supercharged spiral umbrella flame stepless regulation energy-saving combustor

A stepless adjustment, burner technology, applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problems of plugging holes, fierce firepower, incomplete combustion, etc., and achieve fast heating, strong firepower, and uniform heat preservation The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

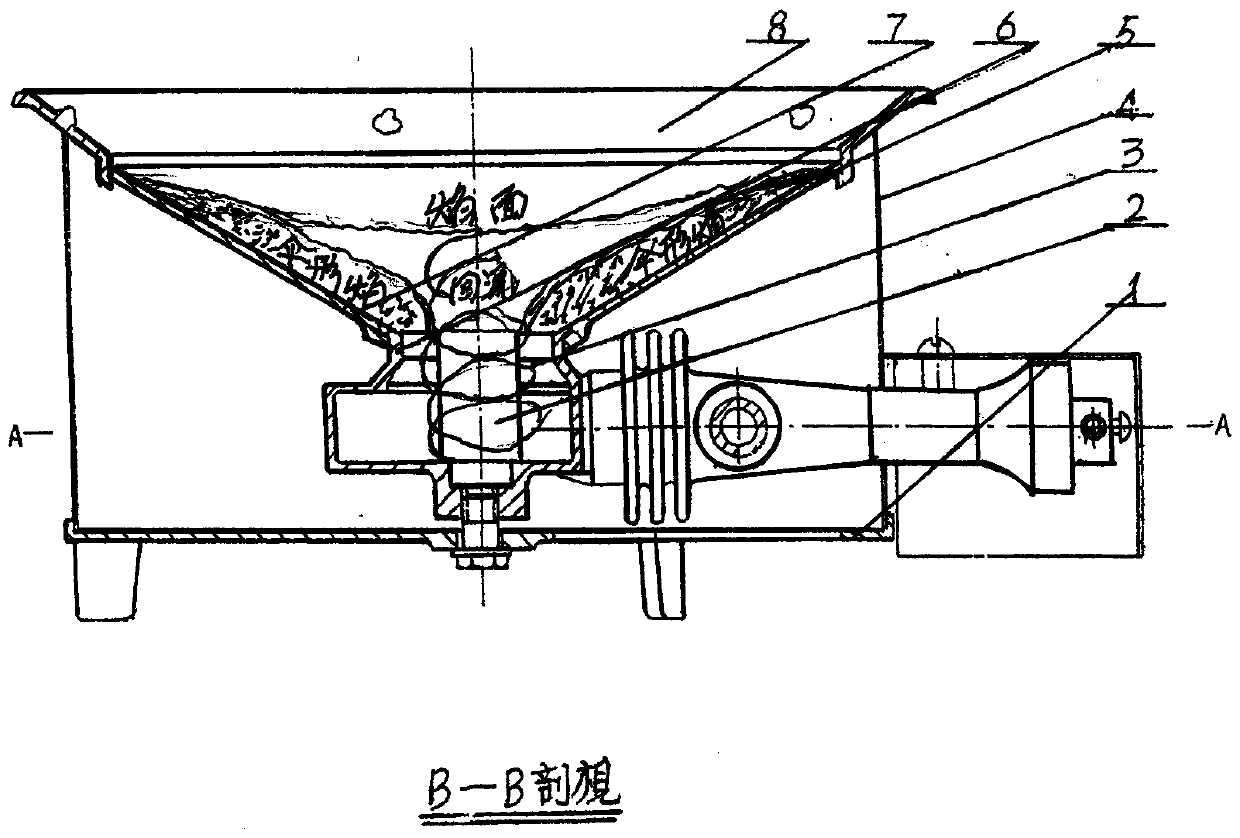

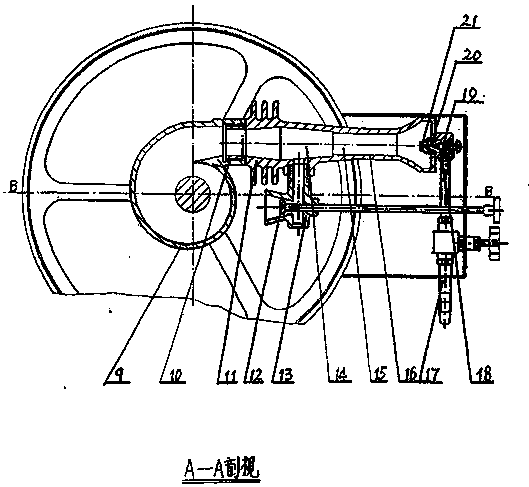

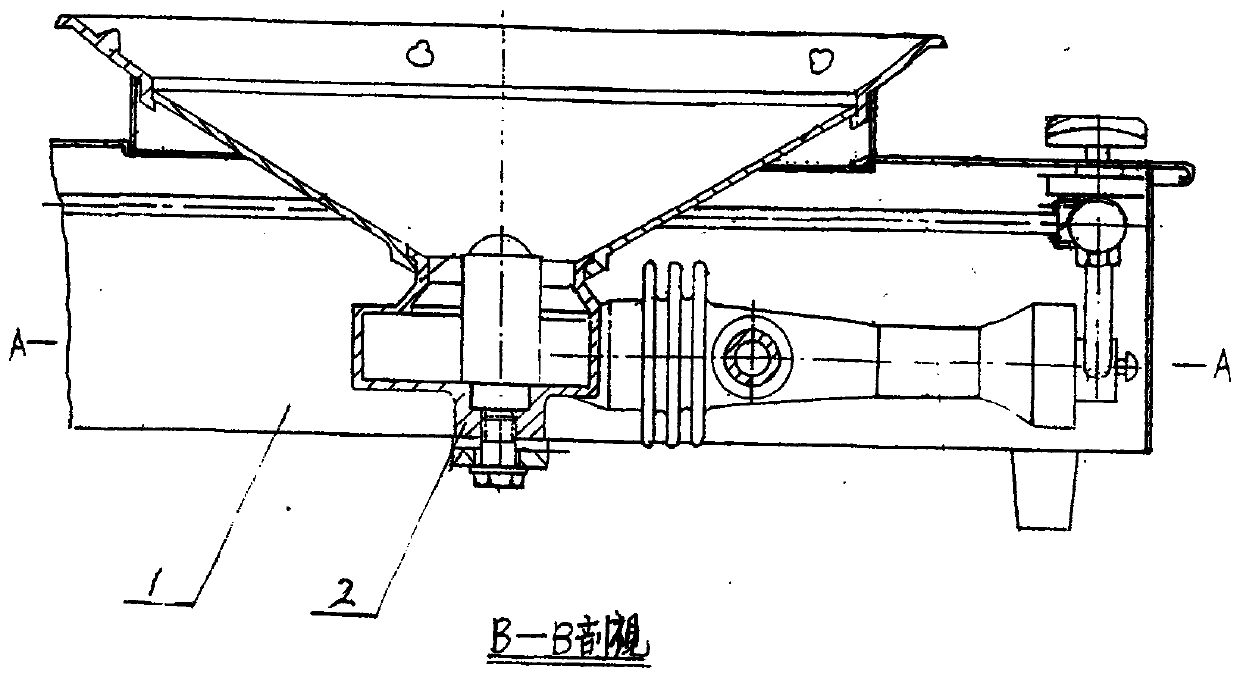

[0013] Example: refer to figure 1 , figure 2 : present embodiment is mainly by nozzle housing (18), needle valve (19), nozzle (21)

[0014] , ejector (16), nozzle (11), cyclone volute (9), expansion-shaped fire path cover (5), stove (8), and base (1). The nozzle housing (18) is made of brass rods, the needle valve (19) is connected in the housing, the outer circle of the valve is processed with external thread, which can be rotated or adjusted on the internal thread of the housing, and one end of the valve body is processed with shrinkage Angle, the outer wall of the middle part of the shell is welded with a gas pipe connected to the gas valve, the front end is connected with a nozzle (21), the nozzle is specially made of brass rod, the inlet of the nozzle is processed with a contraction angle (20), the shell ( 18) The external thread at the front end is connected or adjusted with the internal thread at the front end of the ejector (16). The ejector is made of cast iron, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com