Sample injection device of chromatographic online analysis system and method of using same to process sample

A technology of an analysis system and a sampling device, which is applied in the field of sampling devices of a chromatographic online analysis system, can solve the problems of sample residue, inability to realize freezing enrichment and heating transmission at the same time, uneven temperature control, etc. The effect of uniform heat preservation and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

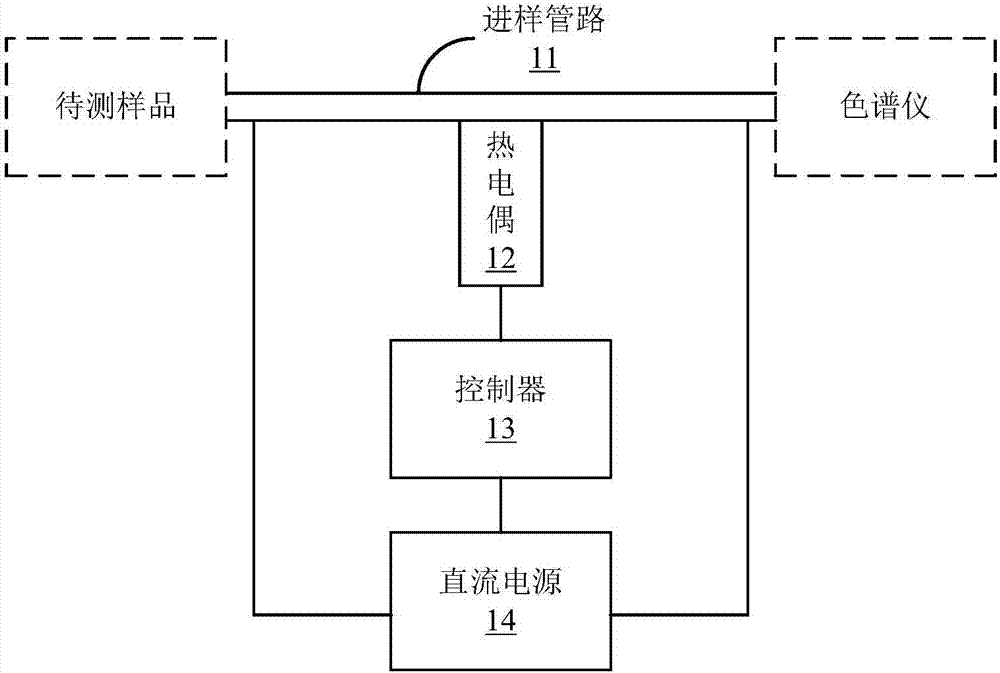

[0028] Such as figure 1 As shown, the sampling device is used to connect the sample to be tested with the chromatograph, and includes a sampling pipeline 11 , a thermocouple 12 , a controller 13 and a DC power supply 14 .

[0029] Specifically, the sampling pipeline 11 is respectively connected to the sample to be tested (such as a sample cell, etc.) and a chromatograph (such as a capillary chromatographic column, etc.), and is a channel for transporting the substance to be tested. The sampling pipeline is a linear tubular passage, and the transmission of compounds with different boiling points is ensured by directly heating the tubular passage during the process of transporting the sample to be tested.

[0030] The sampling pipeline 11 is made of a uniform metal material (such as stainless steel), which can conduct electric current, and because the sampling pipeline 11 itself has a certain resistance, after it is connected into the current loop, the sampling pipeline 11 will ...

Embodiment 2

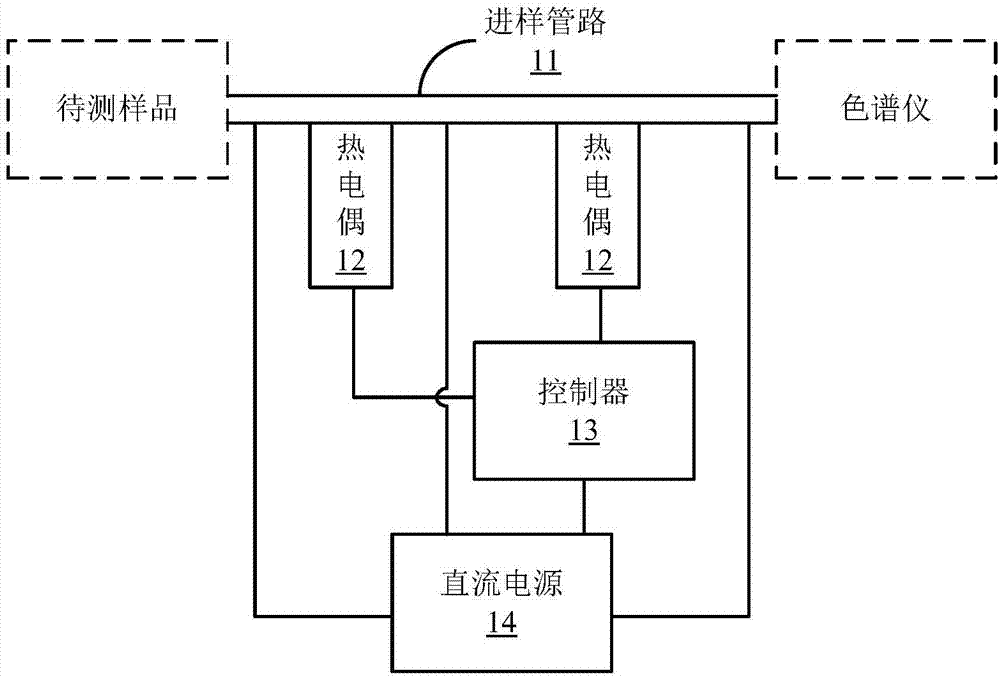

[0039] In this embodiment, the direct current power supply 14 is used to form a current loop in any part of the sample injection pipeline 11, thereby achieving segmental heating of the sample to be tested.

[0040] Such as figure 2 As shown, a pair of input ends and output ends of a DC power supply are also provided between the sample inlet and the sample outlet of the sample injection pipeline 11 . If the input end of the DC power supply has been set at the injection port of the sampling pipeline 11, the input end and the output end of the DC power supply between the injection port and the sample outlet form a current loop, and the The input end of the DC power supply between the mouth and the sample outlet and the output end of the DC power supply at the sample outlet of the sampling pipeline 11 constitute another current loop, so that two loops are formed on the entire sampling pipeline 11. current loop.

[0041] Furthermore, if a plurality of DC power supplies with the sa...

Embodiment 3

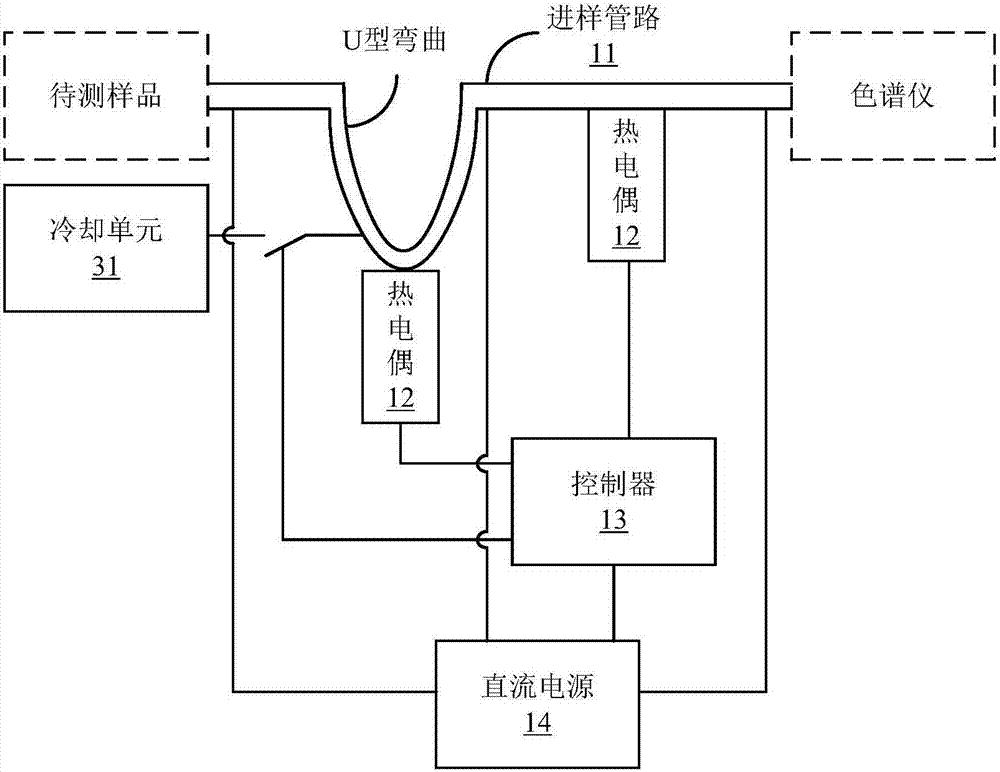

[0045] In this embodiment, the enrichment of the sample to be tested is achieved by changing the local shape of the sampling pipeline.

[0046] Such as image 3 As shown, a section of the sampling pipeline 11 has a U-shaped bend structure, and a cooling unit 31 is also provided corresponding to the U-shaped curved pipeline.

[0047] The cooling unit 31 is connected to the controller 13, and under the instruction control of the controller 13, the cooling unit 31 is loaded onto the U-shaped curved sampling pipeline, or the cooling unit 31 is removed from the U-shaped curved sampling pipeline. uninstall. The substance to be tested can be frozen and enriched at the U-shaped curved sampling pipeline, and then vaporized through the heating pipeline and enter the chromatograph to complete the analysis.

[0048] Specifically, before the heating current is applied, the cooling unit 31 is first connected to the U-shaped bending area, substances with different boiling points can be enr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com