Incubator capable of automatically removing condensed water

A technology of condensate water and incubator, which is applied to specific-purpose bioreactors/fermenters, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of condensate water contamination of culture medium, etc. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

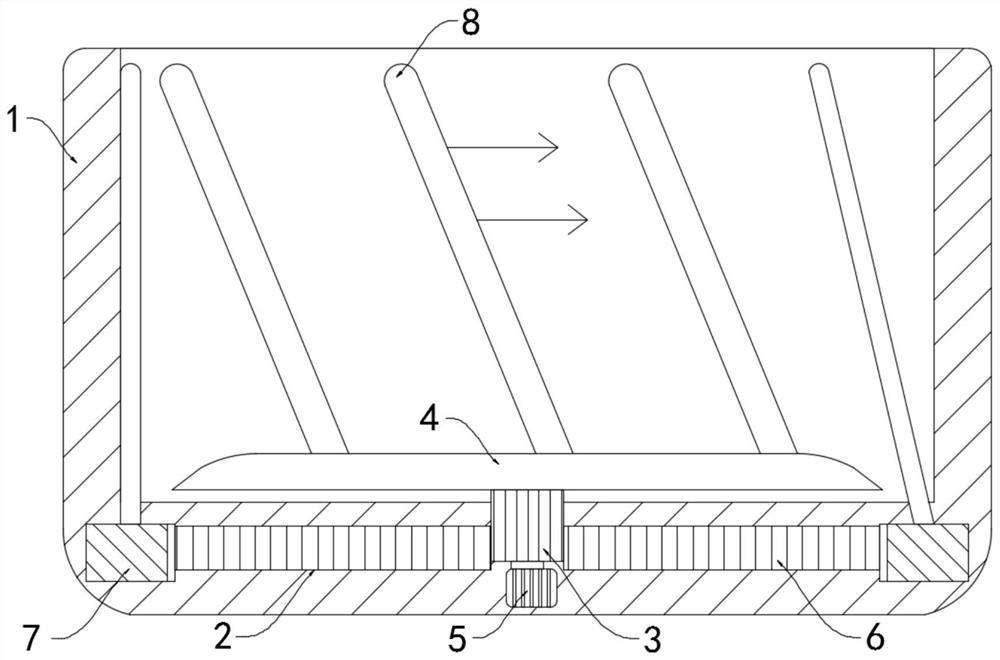

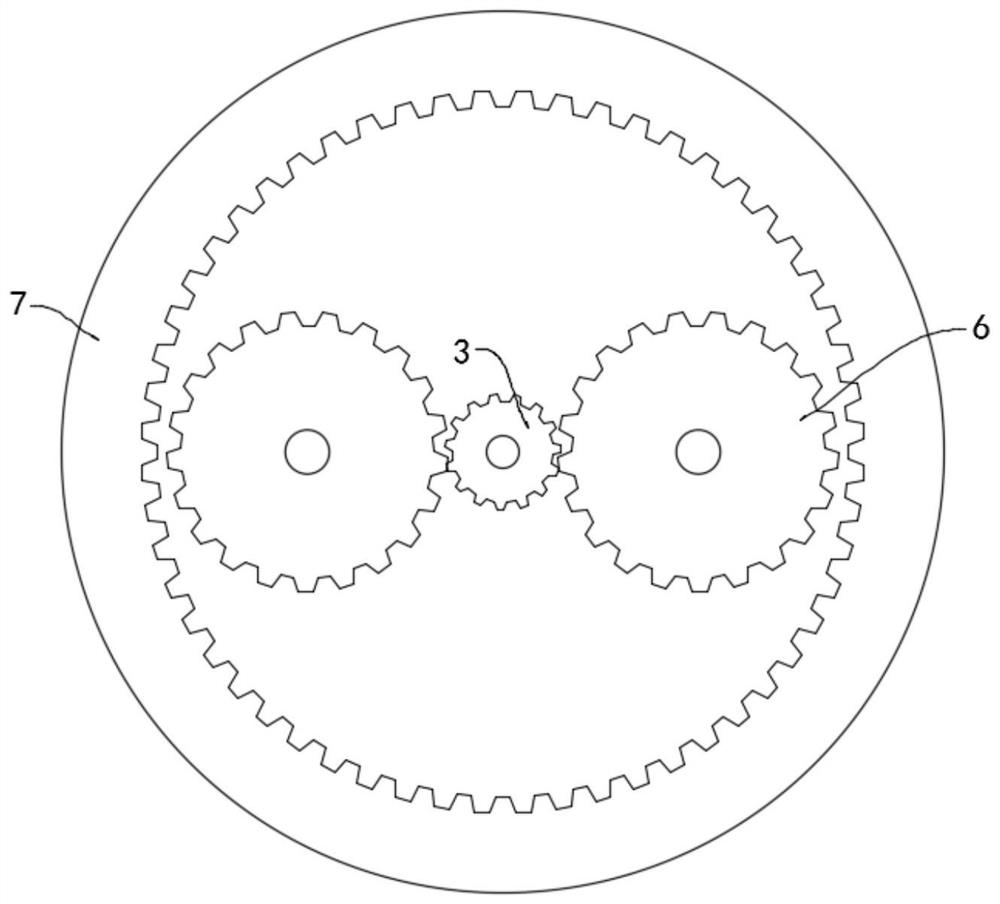

[0026] Such as Figure 1-2 As shown, a constant temperature box that can automatically remove condensed water includes a horizontally arranged box body 1, a transmission chamber 2 is provided in the lower side wall of the box body 1, and a central gear 3 is rotatably connected to the center of the transmission chamber 2. The central gear The upper end of 3 extends into the box body 1 and is fixedly connected with a carrier plate 4 on which the culture dish is placed.

[0027] A motor 5 is fixedly installed at the lower end of the transmission chamber 2, and the motor 5 is coupled with a controller (not shown in the figure), the controller will control the opening and closing of the motor 5 according to the amount of condensed water inside the box body 1, and the output terminal of the motor 5 is connected to the The lower side wall of the central gear 3 is coaxially fixedly connected.

[0028] Both sides of the central gear 3 are meshed with a planetary gear 6, and the two pl...

Embodiment 2

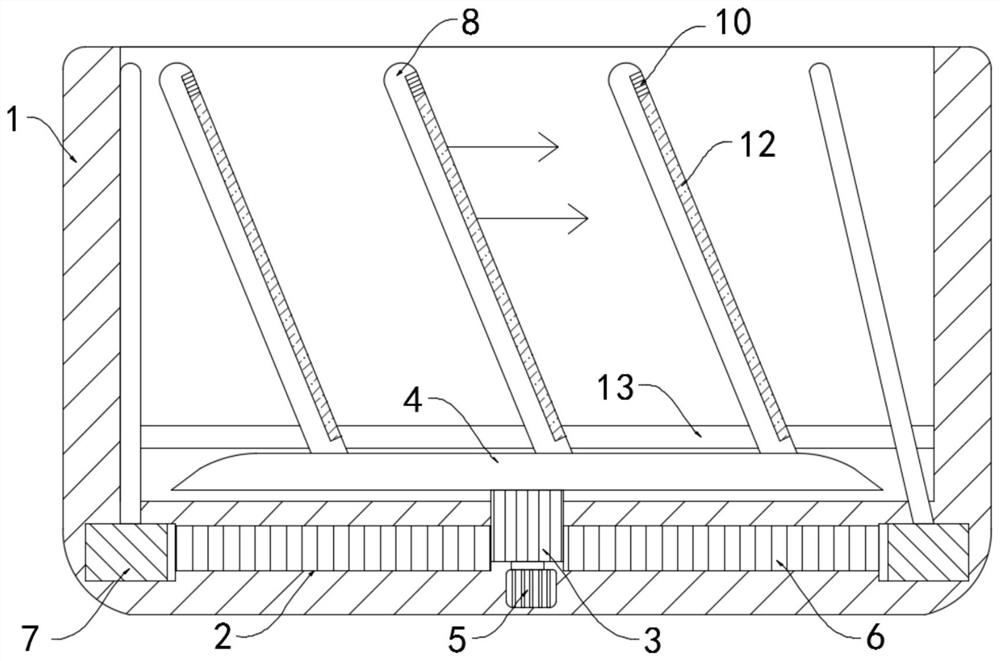

[0034] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that a placement groove 9 is provided on the side wall of the scraper strip 8, and an elastic corrugated tube 10 is fixedly connected to the inner top surface of the placement groove 9. It should be noted that the elastic corrugated pipe The tube 10 contains silver bromide particles and is transparent.

[0035] The lower end of the elastic bellows 10 is fixedly connected with a push block 11, and the lower end of the push block 11 is provided with a water-absorbing strip 12, which is a sponge product, and the water-absorbing strip 12 is placed in the placement groove 9. It should be noted that the placement groove 9 The notch is set smaller than the bottom of the groove, and the water-absorbing strip 12 is limited and fixed to prevent the water-absorbing strip 12 from slipping off from the placement groove 9 in the process of being squeezed.

[0036] The inner wall of the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com