Injection molding equipment and injection molding method for water heater insulation layer

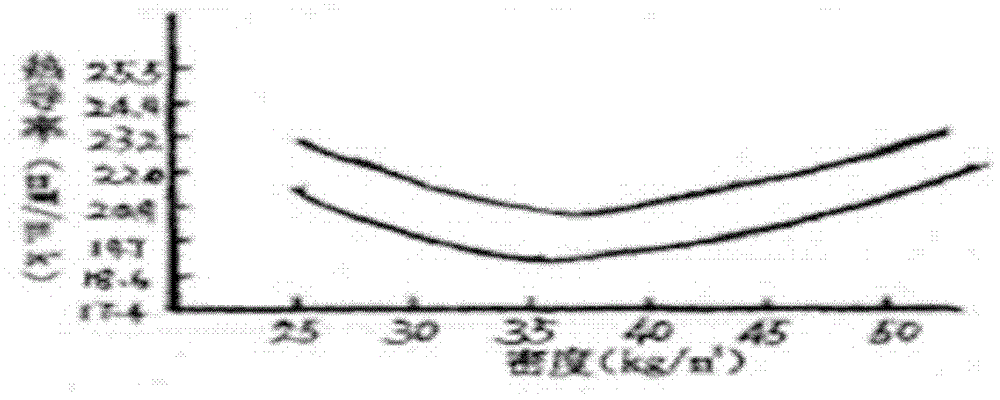

A technology for injection molding equipment and water heaters, which is applied in the field of injection molding equipment for the insulation layer of water heaters. It can solve problems such as large differences in density and thermal conductivity, decline in thermal insulation performance, and uneven heat loss, so as to reduce heat loss, improve thermal insulation performance, Strengthen the effect of fixed position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

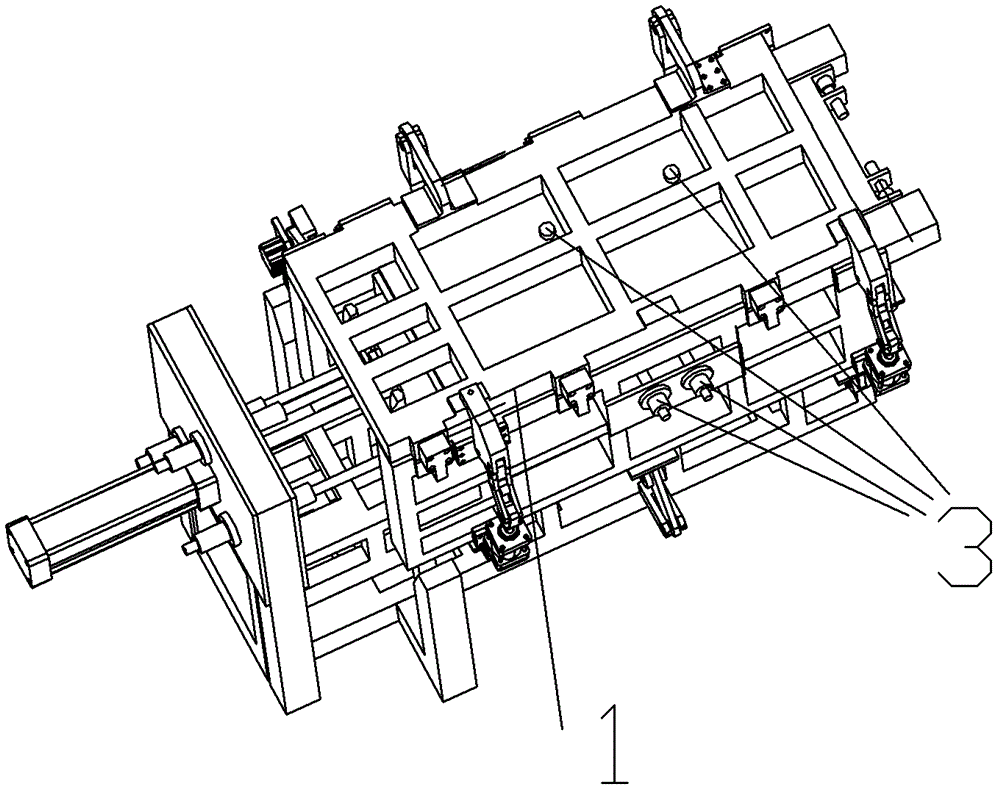

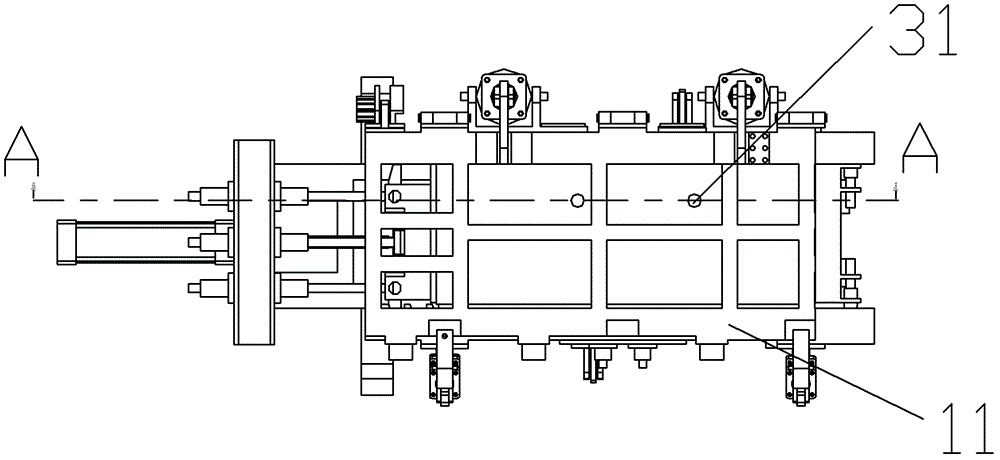

[0037] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0038] When injecting the insulation layer of the water heater, the outer casing and the inner tank of the water heater should be positioned first, so that a space distance can be filled with foam material between the two, and the relative position of the two should be kept fixed during the injection process. . According to the prior art, the wall-mounted rear plate 51 of the water heater casing 5 is usually set as a detachable structure, such as Figure 9 and Figure 10 shown. That is, when the wall-hanging back plate 51 is detached, an opening is formed on the shell 5 , and the liner 7 can be put into the shell 5 . Moreover, the positions of the outer wall hanger 71 of the water heater liner 7 and the wall-mounted rear plate 51 of the casing 5 are corresponding. When the water heater was in the installation position, the wall-mounted rear plate 51...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com