Over-flow type maguesium alloy melt quantitative transfering apparatus

A transfer device, magnesium alloy technology, applied in the direction of lighting and heating equipment, furnace components, furnace types, etc., can solve the problems of pneumatic devices, inconvenient equipment maintenance, long flow stroke, etc., to achieve easy disassembly and maintenance, reduce Effect of gas consumption and reduction of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

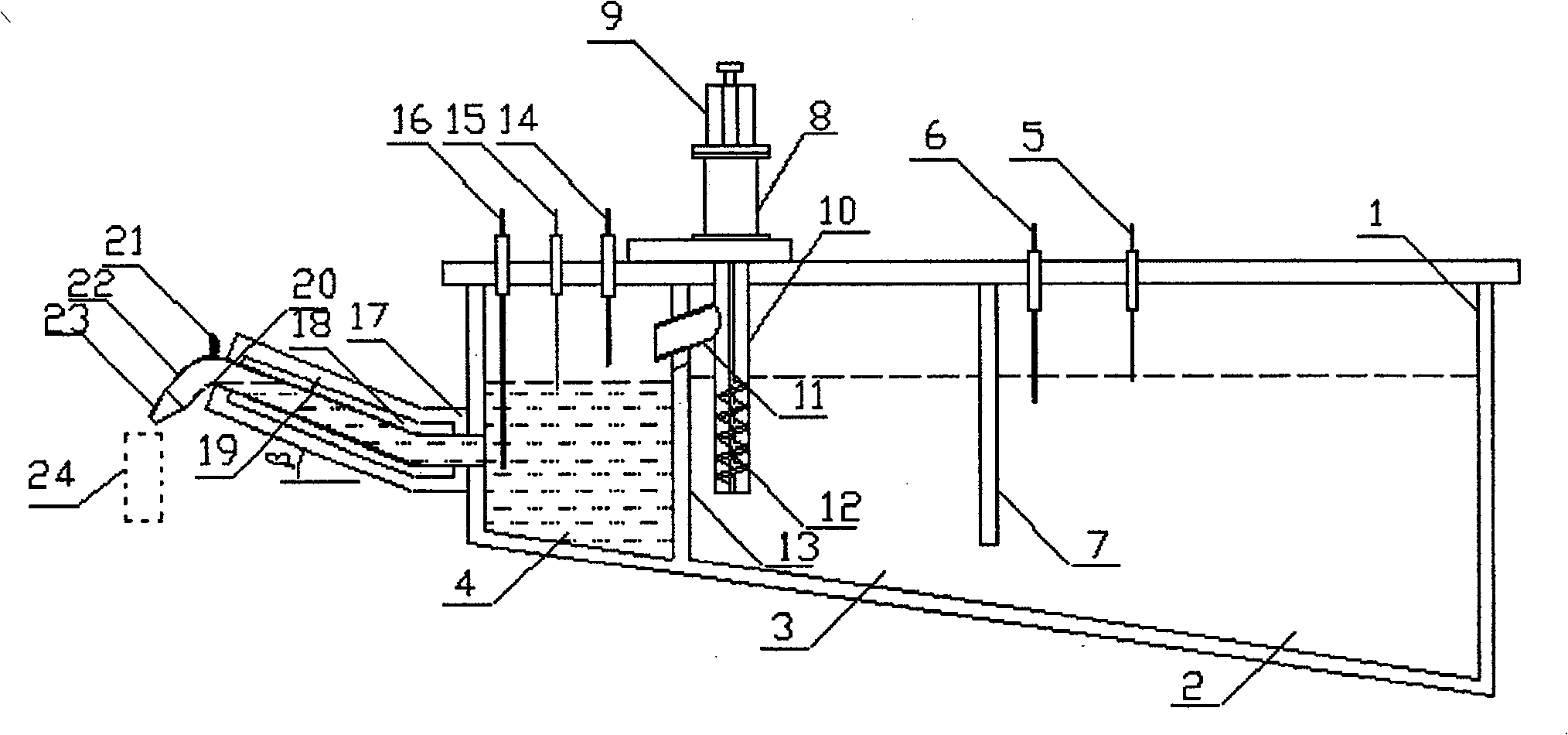

[0012] The specific structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] The overflow type magnesium alloy melt quantitative transfer device provided by the present invention comprises a crucible 1, a quantitative pump 8 and a feeding pipe 22, and a melting chamber 2, a heat preservation chamber 3 and a quantitative chamber 4 are arranged in the crucible; the melting chamber and the heat preservation chamber Heating and heat preservation are carried out independently; a high liquid level probe 5 and a low liquid level probe 6 are installed in the melting chamber, and the liquid level of the melting chamber and the heat preservation chamber is controlled between the high and low liquid level probes, so the liquid level can be ignored The influence of small changes of the quantitative pump on the amount of melt transferred by the quantitative pump; the melting chamber and the heat preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com