Carbon fiber thermal insulation material and preparation method thereof

A thermal insulation material and carbon fiber technology, applied in the direction of heating/cooling fabrics, non-woven fabrics, textiles and papermaking, etc., can solve the problems of cumbersome production process, poor thermal insulation effect, complex components, etc., and achieve uniform thermal insulation effect and stable structure , the effect of simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

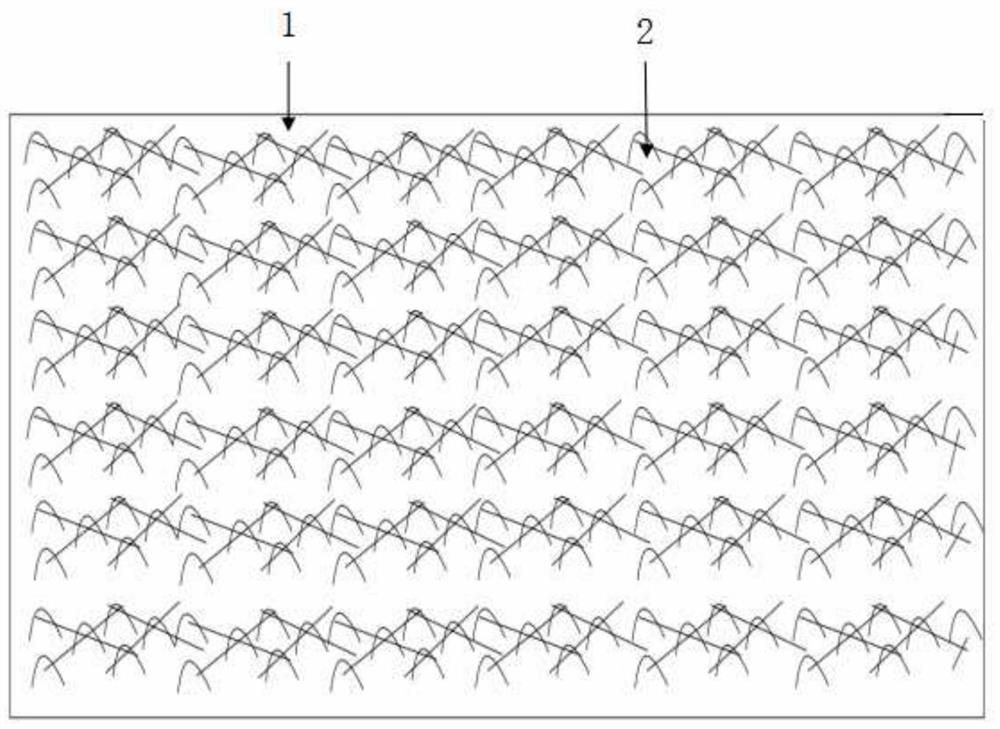

[0021] Example 1, such as figure 1 As shown, the carbon fiber heat insulation material is composed of carbon fiber 1 and phenolic resin fiber 2 evenly distributed; the carbon fiber 1 and phenolic resin fiber 2 are woven, pressurized and solidified, and then connected by a graphitization process.

[0022] Exemplarily, the ratio of the carbon fiber 1 to the phenolic resin fiber 2 is 1:0.3.

[0023] Exemplarily, the ratio of the carbon fiber 1 to the phenolic resin fiber 2 is 1:0.5.

[0024] Exemplarily, the ratio of the carbon fiber 1 to the phenolic resin fiber 2 is 1:0.8.

[0025] Exemplarily, the thickness of the carbon fiber heat insulating material is 20mm.

[0026] Exemplarily, the thickness of the carbon fiber heat insulating material is 150mm.

[0027] Exemplarily, the thickness of the carbon fiber heat insulating material is 300mm.

[0028] In one embodiment of the present invention, the carbon fiber heat insulating material has a density of 0.13g / cm 3 , the therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com