Heating and heat insulating feeder sleeve

A technology of thermal insulation riser sleeve and heating layer, applied in the field of metallurgical casting, can solve the problem that the thermal insulation performance cannot meet the actual production needs, etc., and achieve the effects of prolonging the solidification time, reducing the volume size, and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

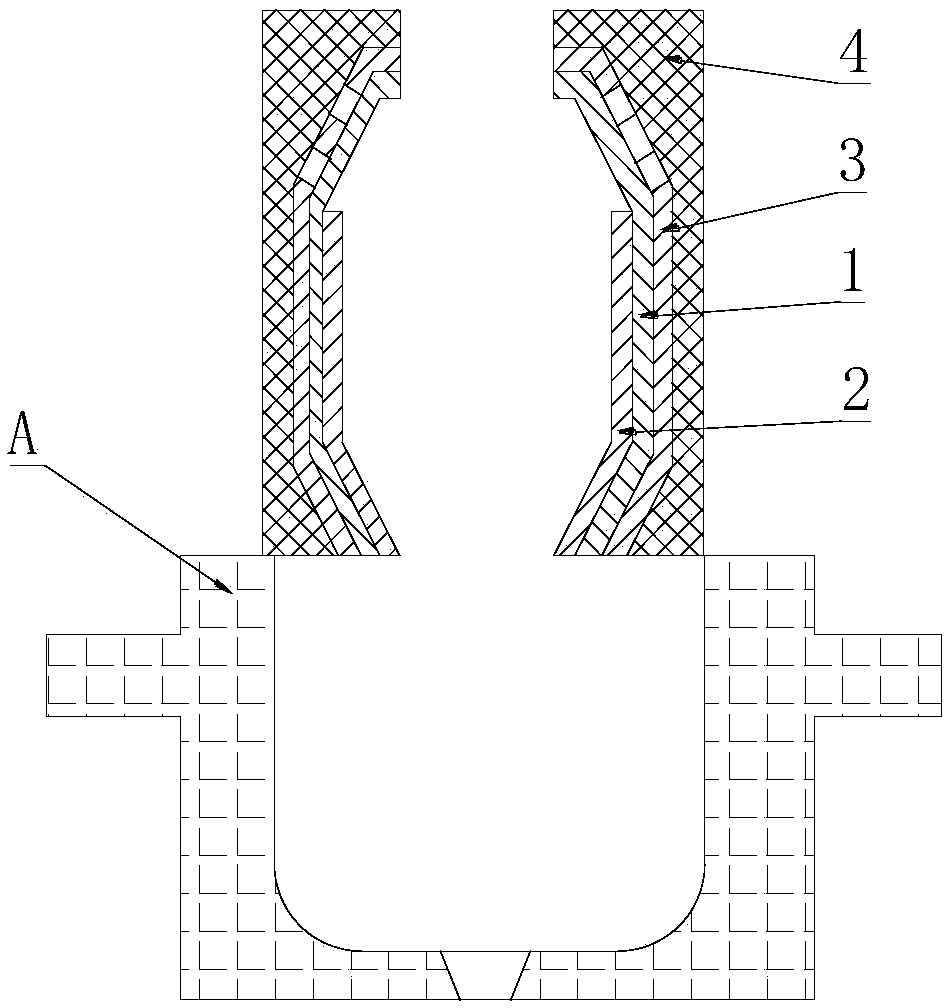

[0021] A heating and heat preservation riser sleeve, used for feeding into a casting mold A, comprising a base body 1, a heating layer 2, an insulation layer 3 and a protective layer 4, and a feeding cavity is opened inside the base body 1, and the feeding cavity The cavity communicates with the inside of the casting mold A, the heating layer 2 is arranged on the inner wall of the feeding cavity, the insulation layer 3 is coated on the outside of the base 1, and the protective layer 4 is coated on the outside of the insulation layer 3; one end of the heating layer 2 is connected to the base 1 The bottom is flush, and the other end of the heating layer 2 is located in the middle of the substrate 1 .

[0022] The insulation layer 3 is made of polystyrene composite material; the raw materials of polystyrene composite material include by weight: 50 parts of expandable polystyrene, 60 parts of polyurethane plastic, 40 parts of nitrile silicone rubber, and 2 parts of physical foaming...

Embodiment 2

[0025] A heating and heat preservation riser sleeve, used for feeding into a casting mold A, comprising a base body 1, a heating layer 2, an insulation layer 3 and a protective layer 4, and a feeding cavity is opened inside the base body 1, and the feeding cavity The cavity communicates with the inside of the casting mold A, the heating layer 2 is arranged on the inner wall of the feeding cavity, the insulation layer 3 is coated on the outside of the base 1, and the protective layer 4 is coated on the outside of the insulation layer 3; one end of the heating layer 2 is connected to the base 1 The bottom is flush, and the other end of the heating layer 2 is located in the middle of the substrate 1 .

[0026] The insulation layer 3 is made of polystyrene composite material; the raw materials of polystyrene composite material include by weight: 80 parts of expandable polystyrene, 40 parts of polyurethane plastic, 50 parts of nitrile silicone rubber, and 1 part of physical foaming ...

Embodiment 3

[0029] A heating and heat preservation riser sleeve, used for feeding into a casting mold A, comprising a base body 1, a heating layer 2, an insulation layer 3 and a protective layer 4, and a feeding cavity is opened inside the base body 1, and the feeding cavity The cavity communicates with the inside of the casting mold A, the heating layer 2 is arranged on the inner wall of the feeding cavity, the insulation layer 3 is coated on the outside of the base 1, and the protective layer 4 is coated on the outside of the insulation layer 3; one end of the heating layer 2 is connected to the base 1 The bottom is flush, and the other end of the heating layer 2 is located in the middle of the substrate 1 .

[0030] The insulation layer 3 is made of polystyrene composite material; the raw materials of polystyrene composite material include: expandable polystyrene 60kg, polyurethane plastic 55kg, nitrile silicone rubber 42kg, physical foaming agent 1.8kg, sodium lignosulfonate 1.8kg, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com