Rotor shaft support structure and supercharger

A technology of supporting structure and rotor shaft, which is applied in the direction of rotating bearings, bearings, bearing assembly, etc., can solve the problems of increased wear of setting holes and semi-floating bushings, and it is difficult to improve the durability of superchargers for vehicles. , to achieve the effect of improving the rotation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

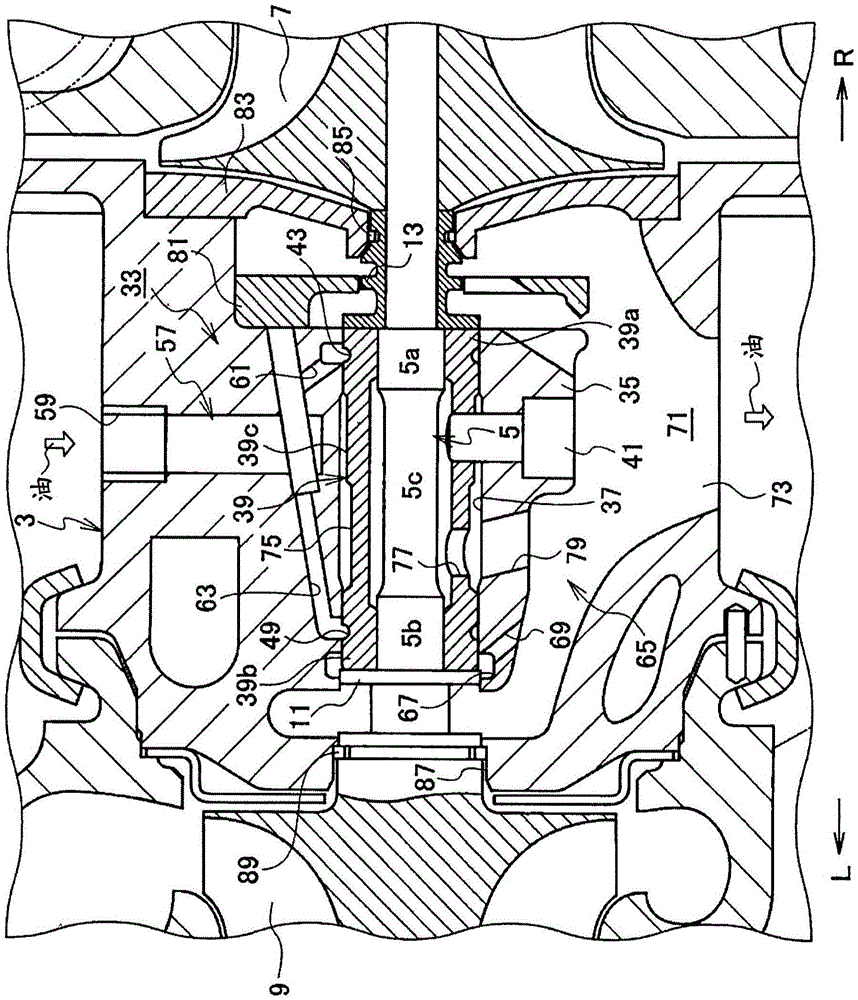

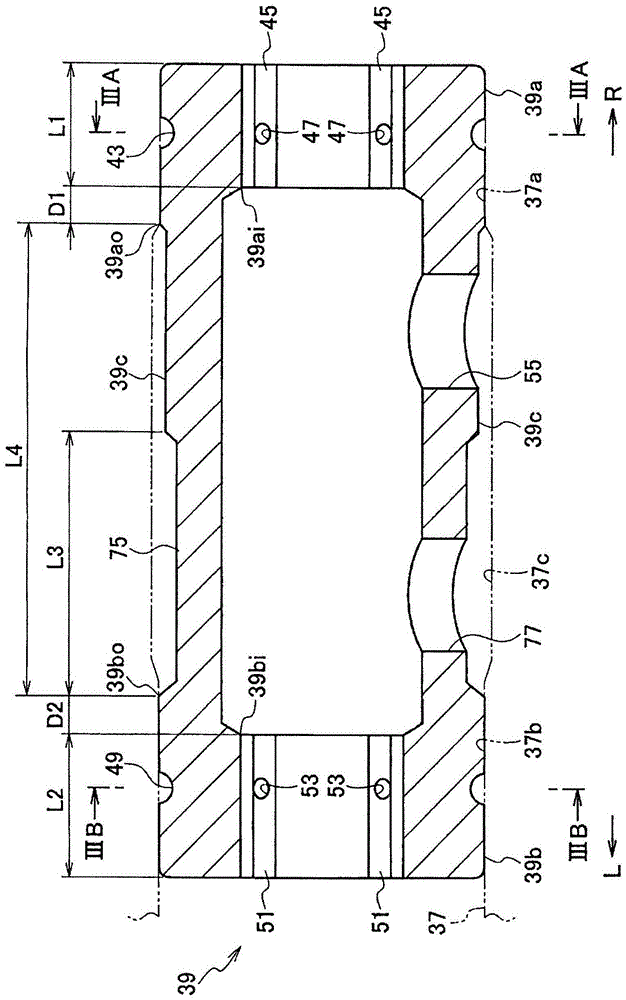

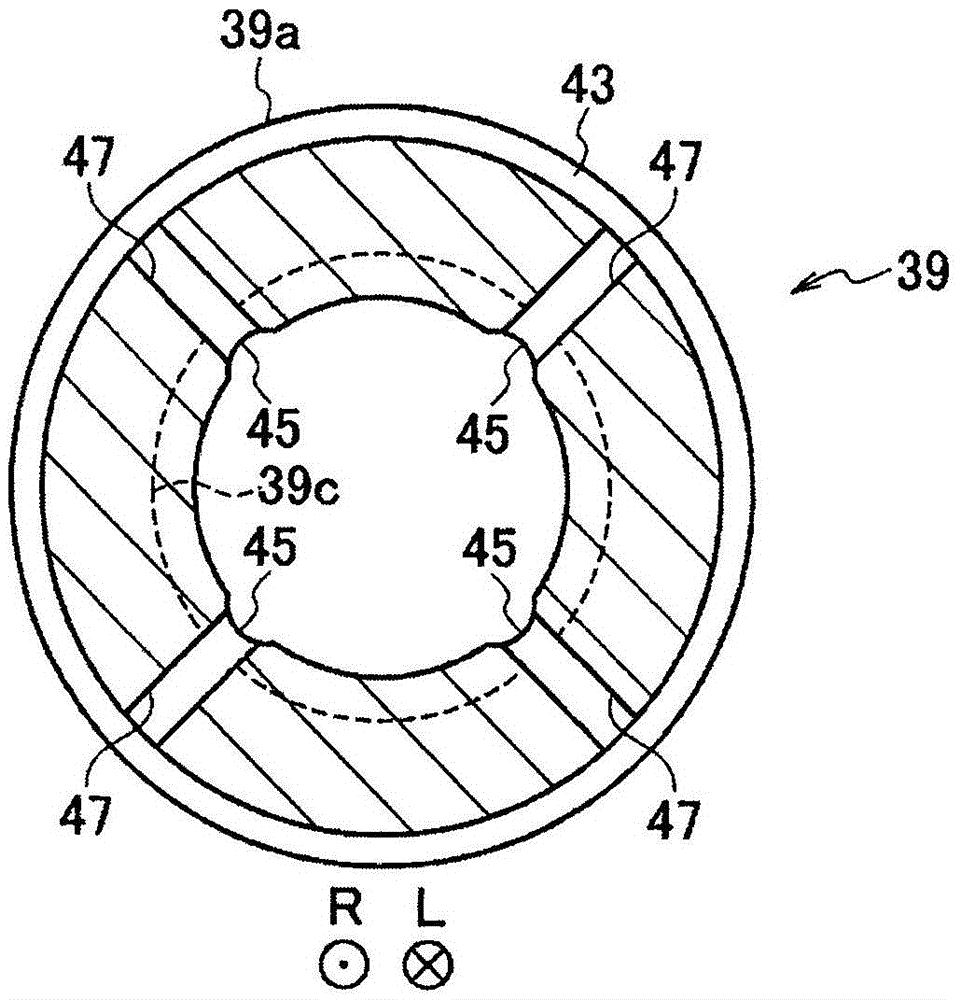

[0023] refer to Figure 1 ~ Figure 4 Embodiments of the present invention will be described. Wherein, as shown in the accompanying drawings, "L" means the left side, and "R" means the right side.

[0024] Such as figure 1 as well as Figure 4 As shown, the vehicle supercharger (an example of a supercharger) 1 according to the embodiment of the present invention supercharges (compresses) the air supplied to the engine by utilizing the pressure energy of the exhaust gas from the engine (not shown). ).

[0025]The vehicle supercharger 1 includes a bearing housing 3 and a rotor shaft (turbine shaft) 5 rotatably provided on the bearing housing 3 and extending in the left-right direction. In addition, a compressor impeller 7 for compressing air by centrifugal force is integrally provided at one end portion (right end portion) of the rotor shaft 5 . The other end (left end) of the rotor shaft 5 is integrally provided with a turbine wheel 9 that generates a rotational force (rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com