Carbon fiber storage circulating fan

A circulating fan and carbon fiber technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem that the storage circulating fan is difficult to meet the requirements of use, and achieve simple and reasonable structure, reduce power consumption, and reduce rotational vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] Referring to the accompanying drawings, the specific implementation is as follows:

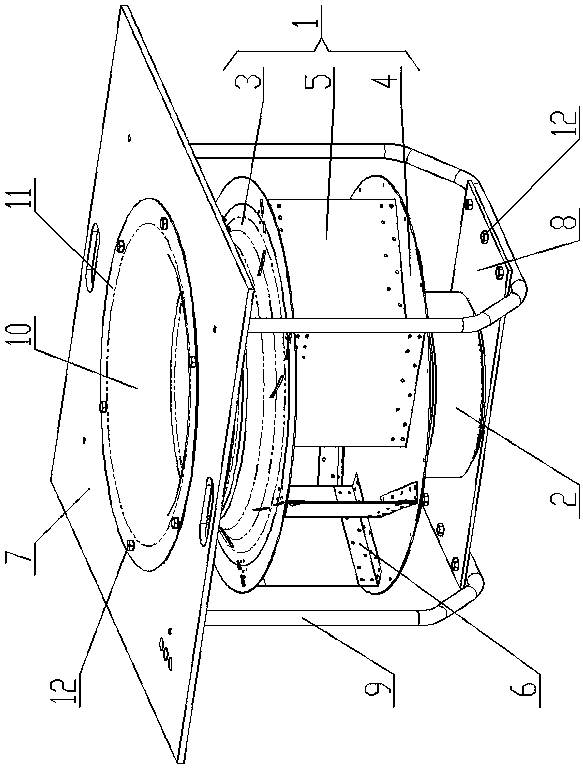

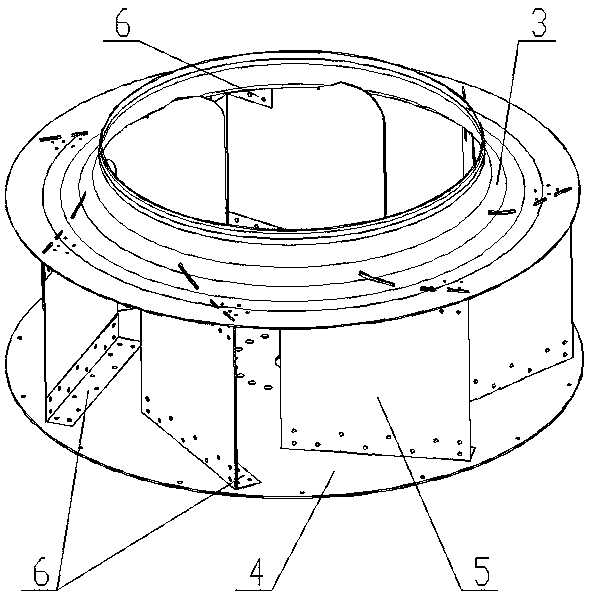

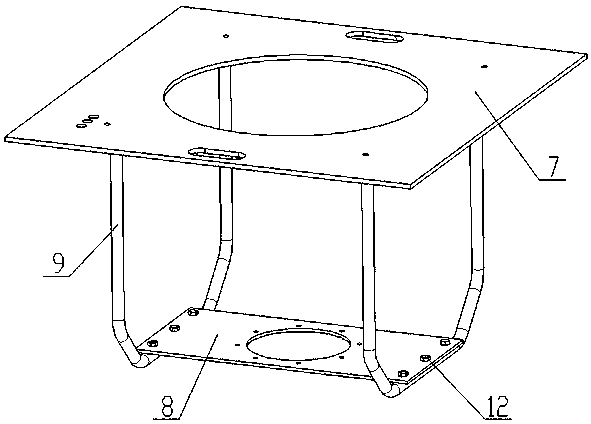

[0024] Such as figure 1 As shown, a carbon fiber storage circulating fan includes a fan impeller 1, a motor 2 and a fan mounting frame, such as figure 2 As shown, the fan impeller 1 includes a front disk 3, a rear disk 4 and a plurality of blades 5, and the plurality of blades 5 are located between the front disk 3 and the rear disk 4 and are arranged at uniform intervals along the circumference of the fan impeller 1. The front disk 3 , the rear plate 4 and the blade 5 are respectively formed by laminating multiple layers of carbon fiber materials along the thickness direction. The carbon fiber material is one of carbon fiber prepreg, carbon fiber dry cloth, carbon fiber powder, and carbon fiber unidirectional yarn. Carbon fiber angle steel 6 is provided on both sides of the connection between the disk 3 and the rear disk 4, one side of the carbon fiber angle steel 6 is attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com