Device for transferring torque from electromotor to compressor

A technology for compressors and motors, applied in transmissions, engines, hoisting devices, etc., can solve problems such as temperature, plastic fracture influence, and rated fracture function dispersion, and achieve the effects of manufacturing error compensation and reducing rotational vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

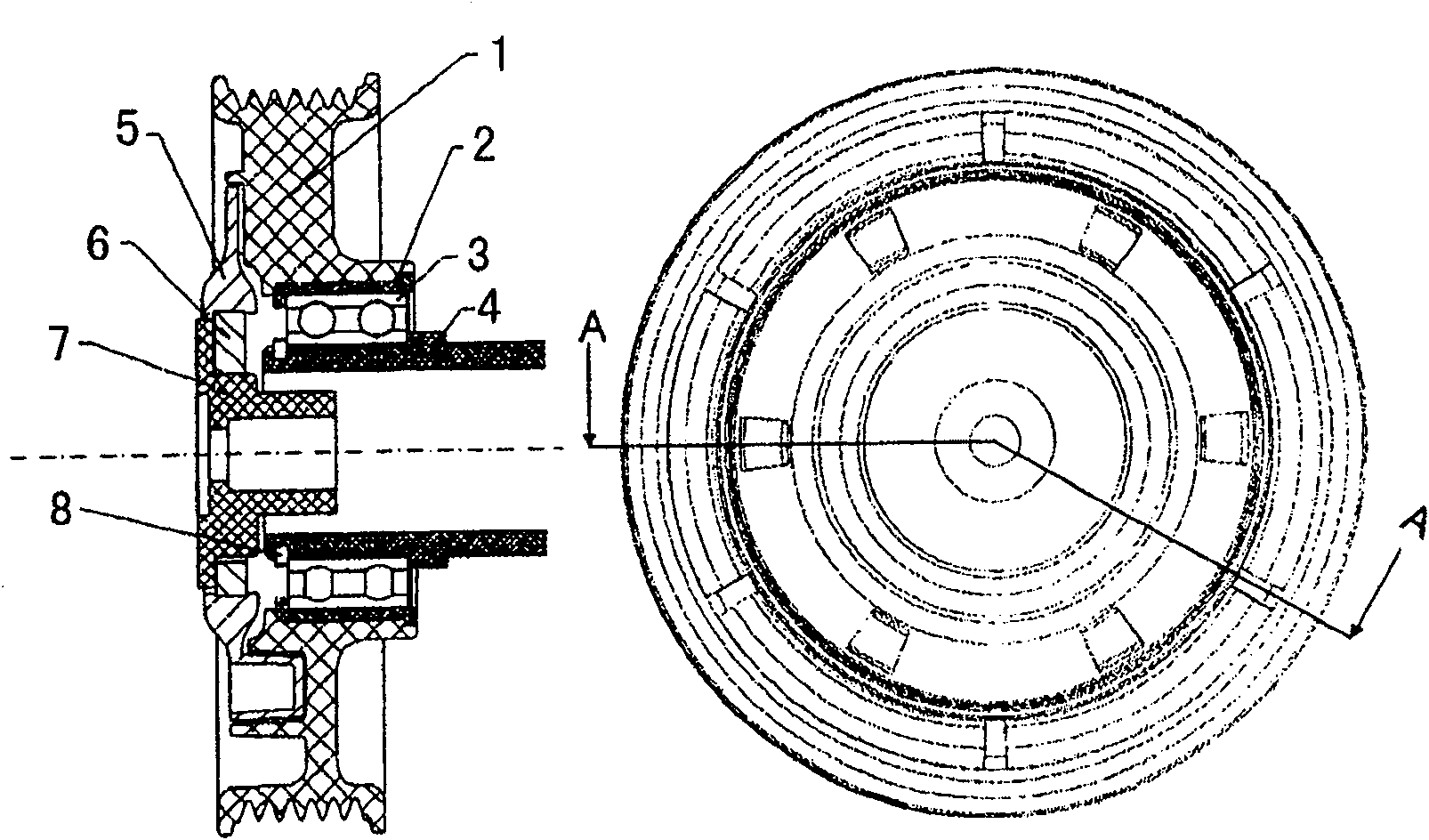

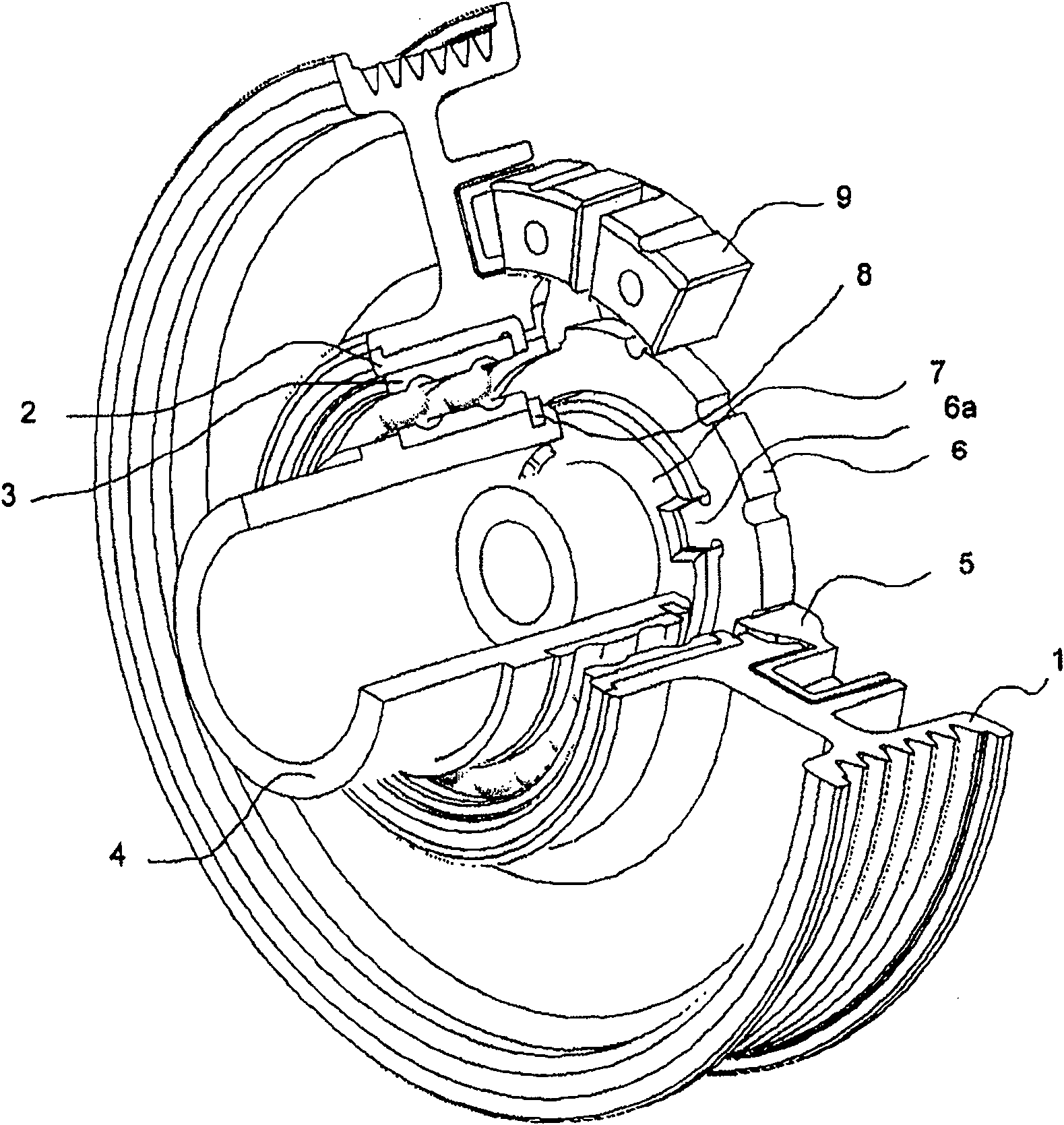

[0029] figure 1 A pulley 1 is shown, which drives the shaft (compressor housing 4 , bearing 3 , steel ring 2 ) of a compressor, not shown here. Between the pulley 1 and the hub 7 is a mechanism for vibration damping and overload protection with the components synchronizer 5 and limiting ring 6 shown in the figure.

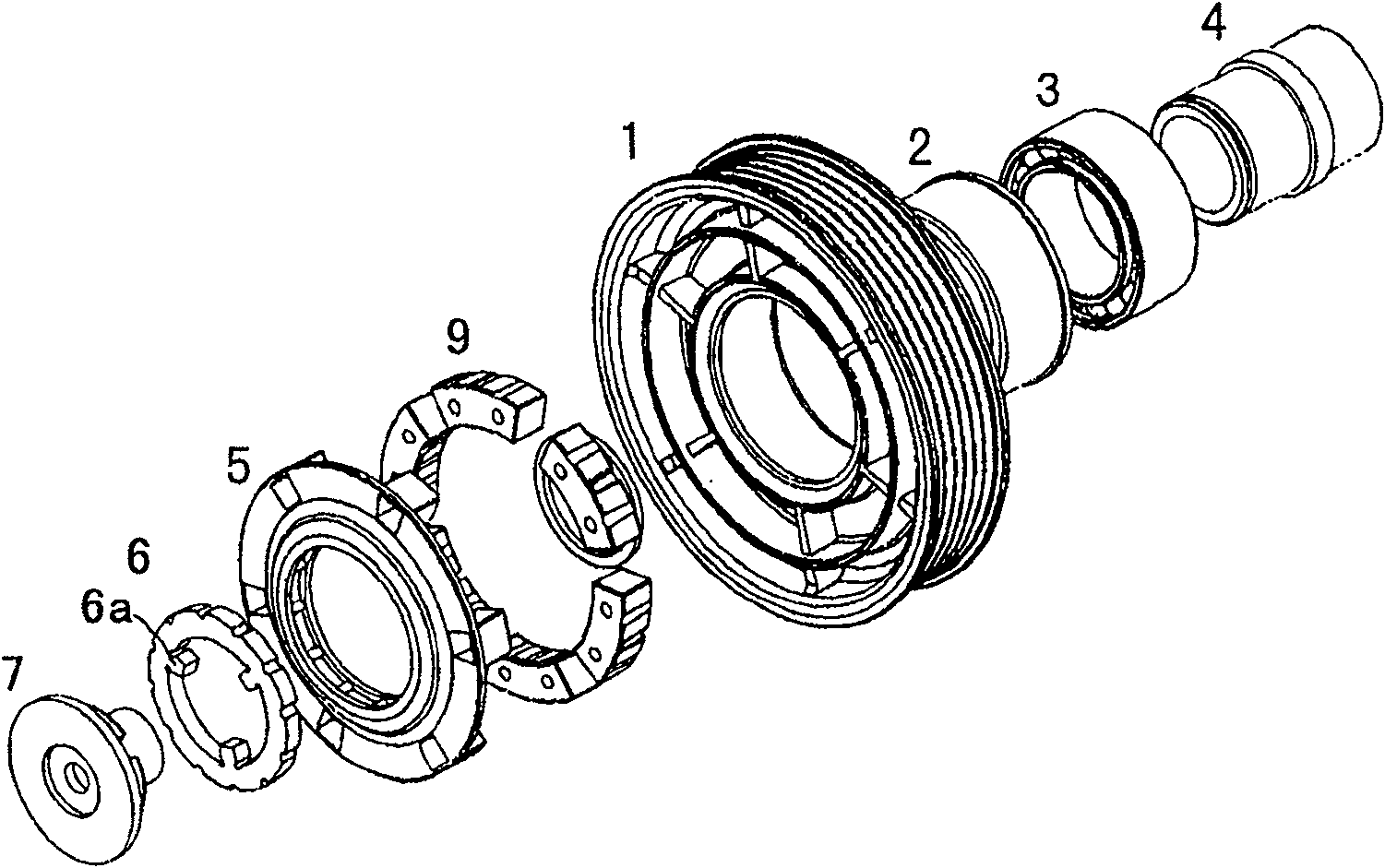

[0030] Also from figure 2 and image 3 As shown in FIG. 3 , the limiting ring 6 has lugs 6 a arranged towards the center, which engage in grooves of the axially arranged hub 7 . The length of the axially arranged outer groove in the hub 7 is designed such that the lug 6 a delimiting the ring 6 is displaceable in the axial direction of the hub 7 . The outer edge of the delimiting ring 6 is surrounded laterally by the synchronizing element 5 , which protrudes axially into the pulley 1 by means of a radially segmented profile. The pulley 1 has the same number of recesses via the ribs, as the synchronization element 5 has raised sections. Between the pulley 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com