Patents

Literature

63results about How to "Good matching precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

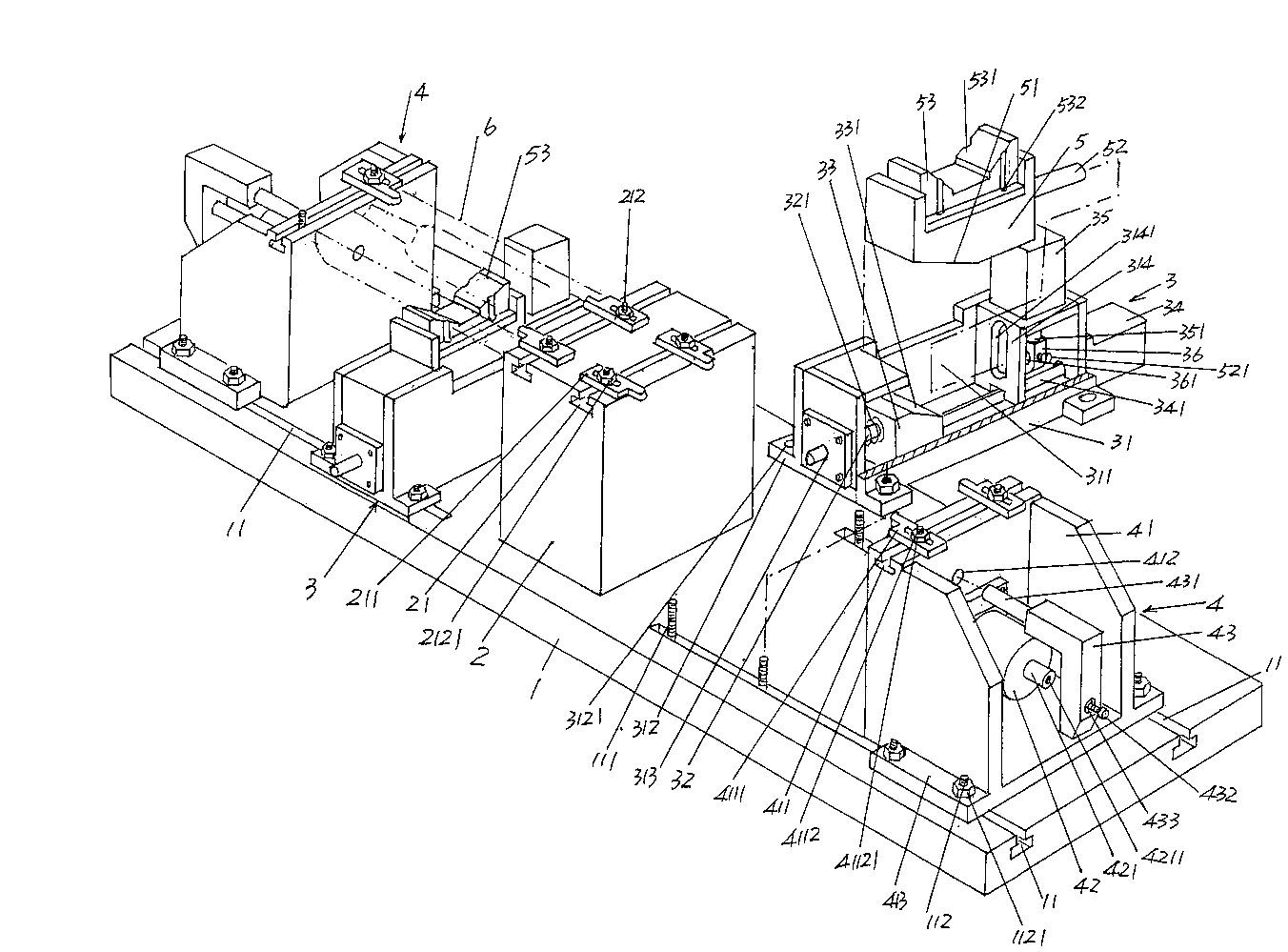

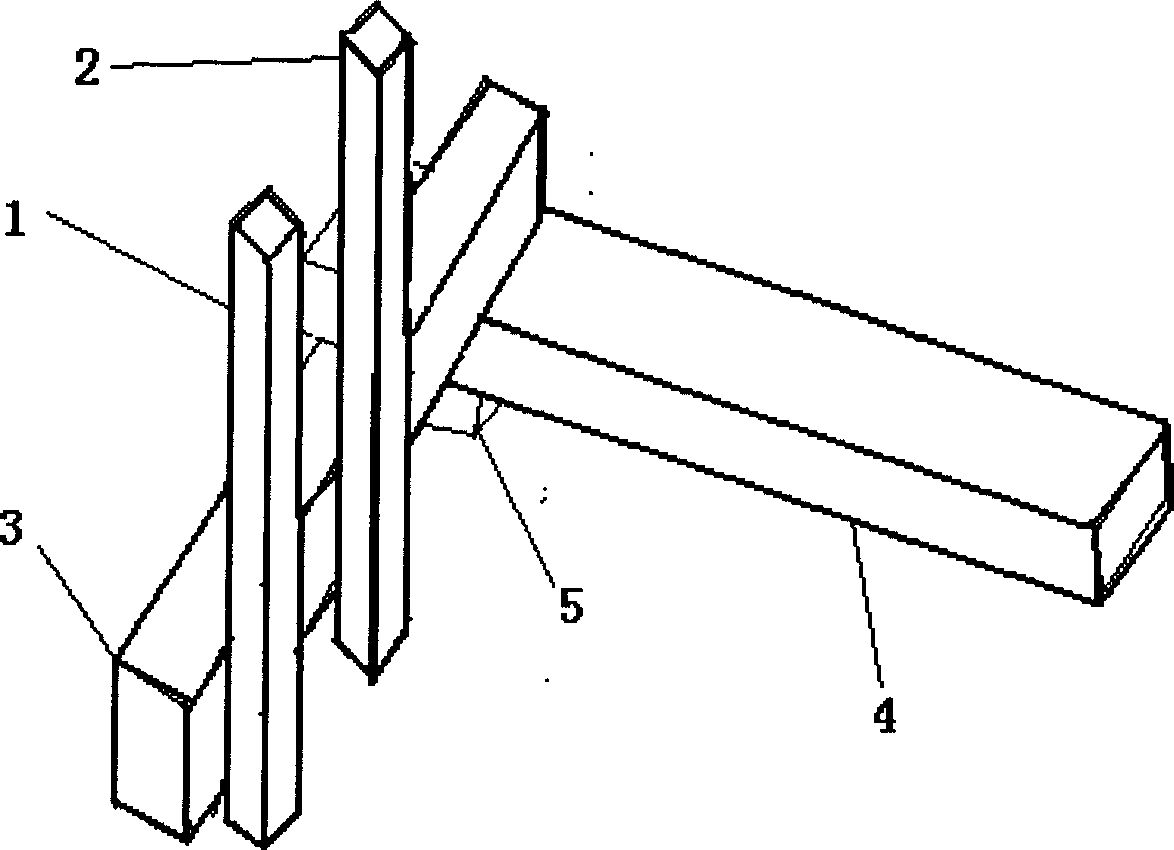

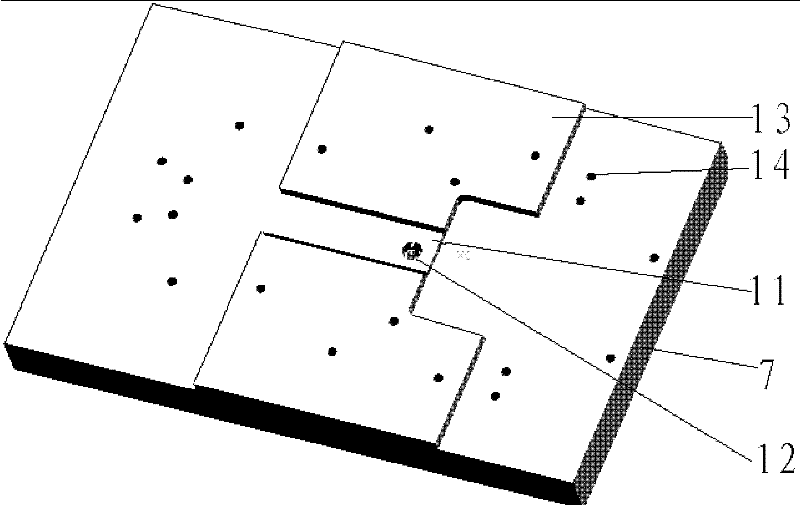

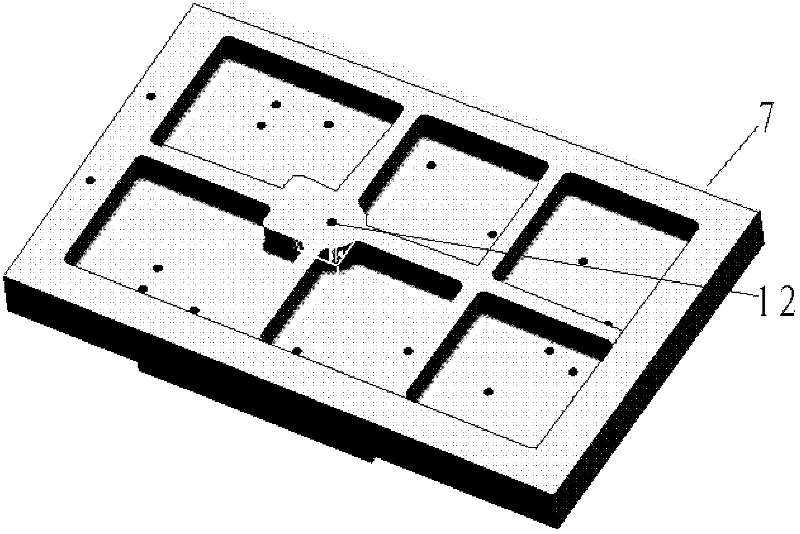

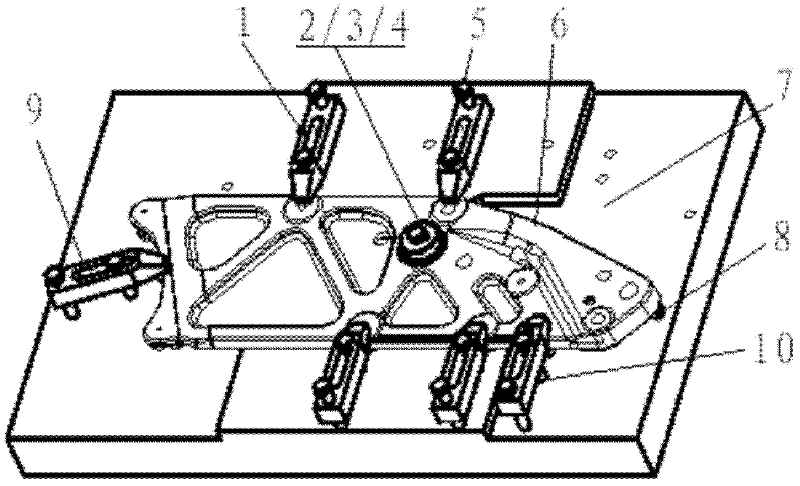

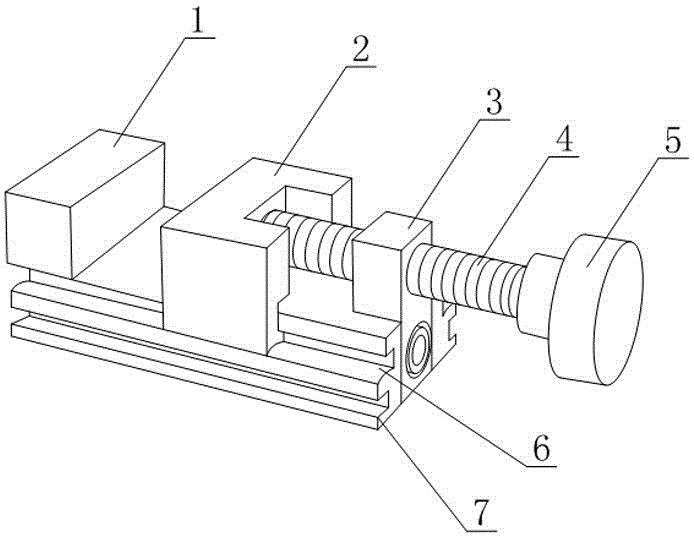

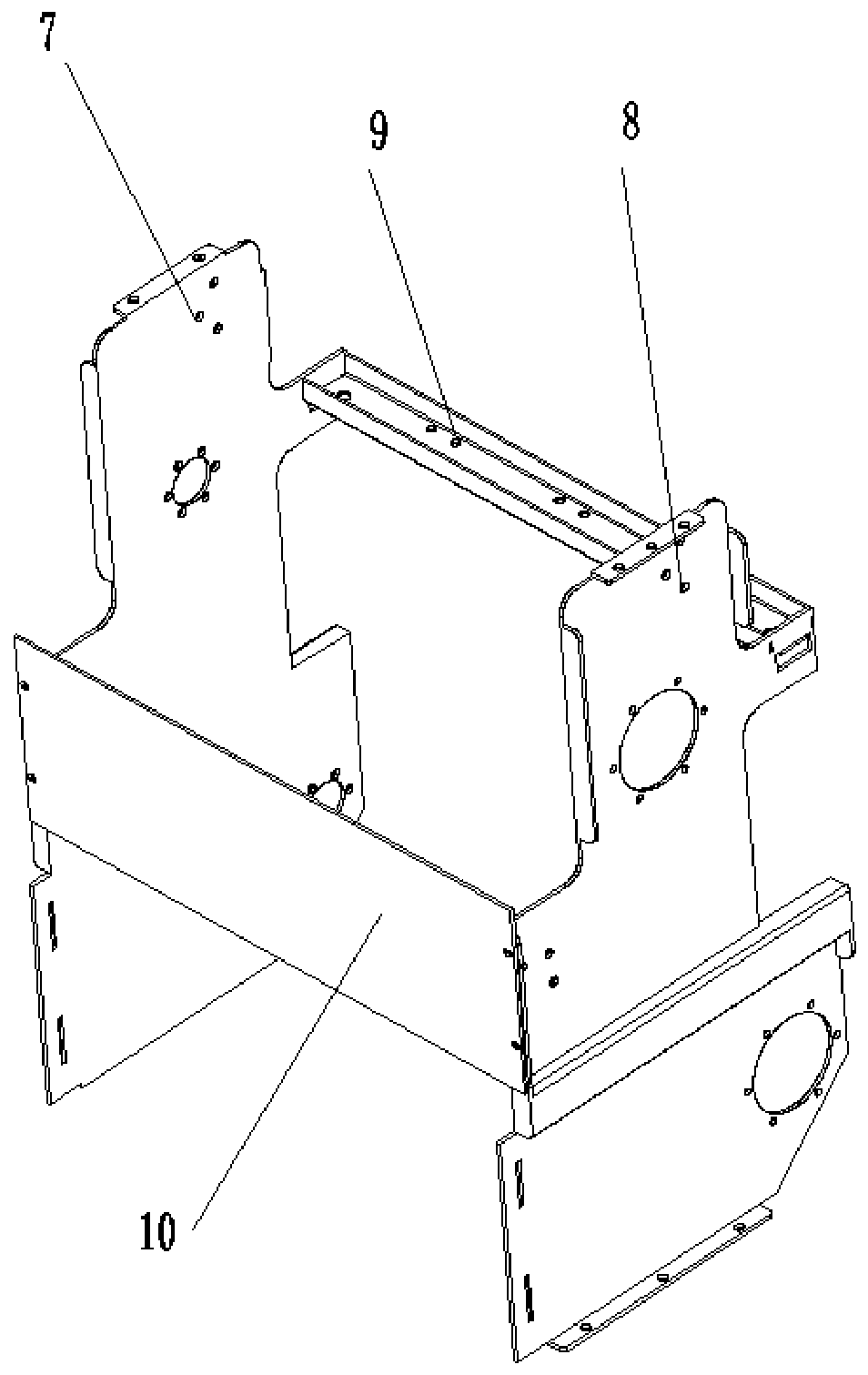

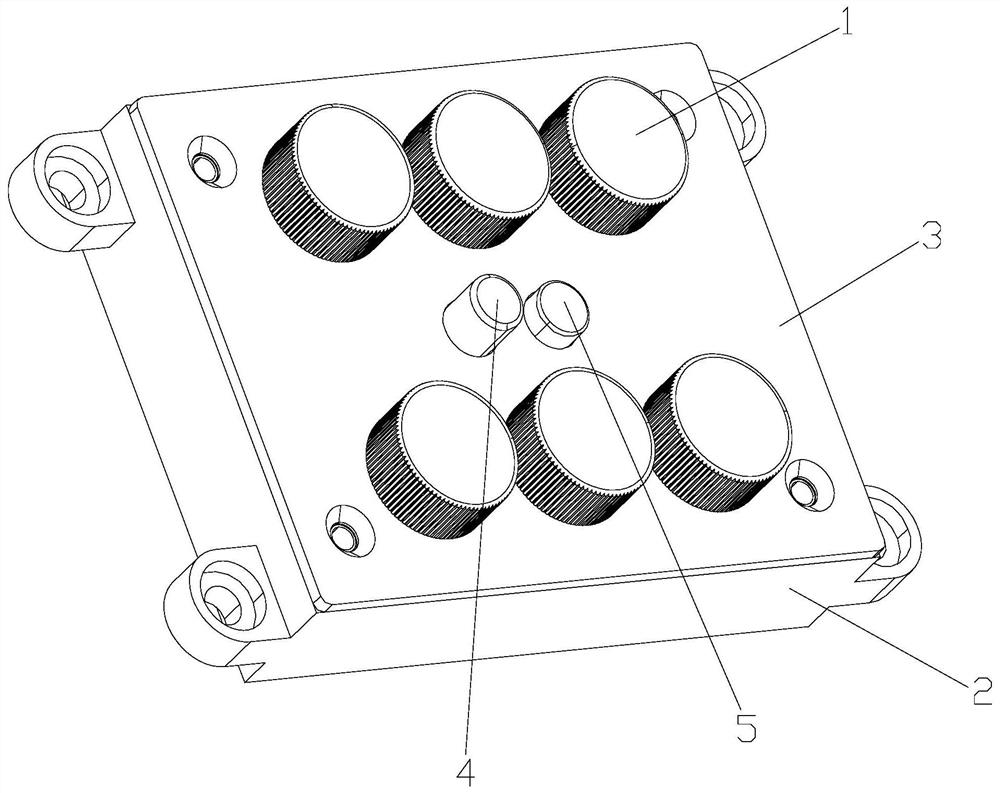

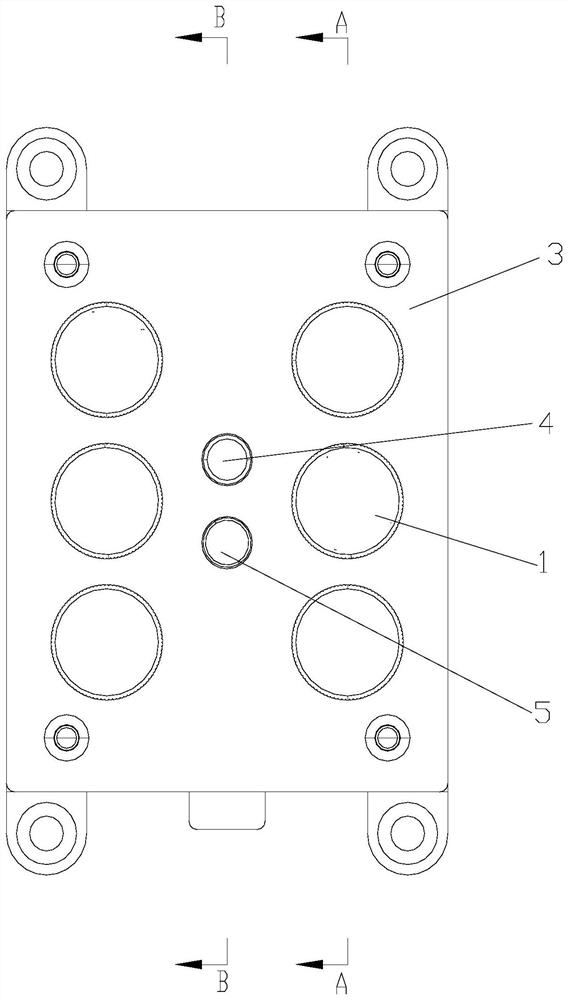

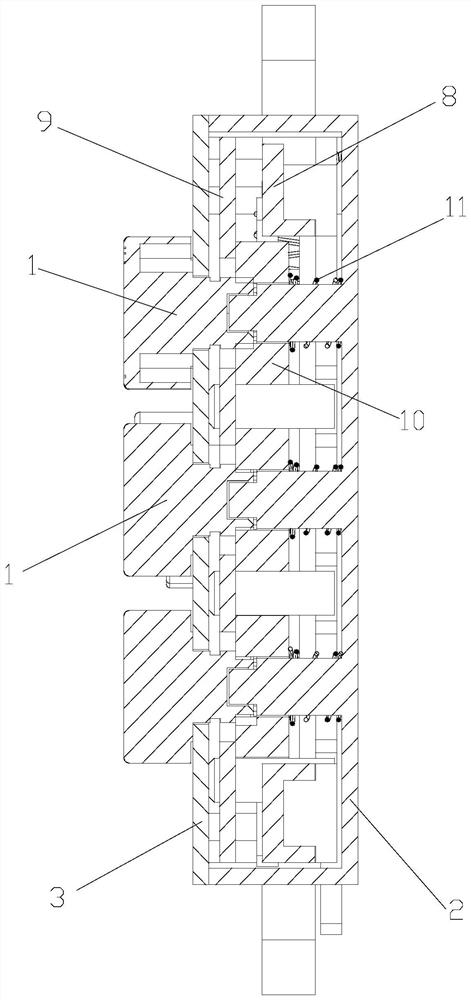

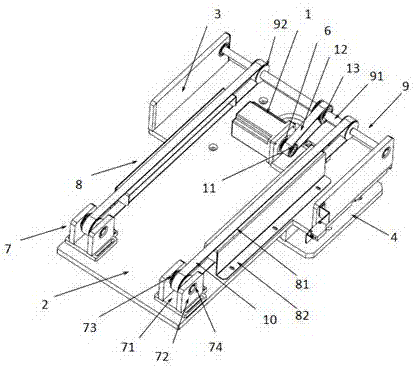

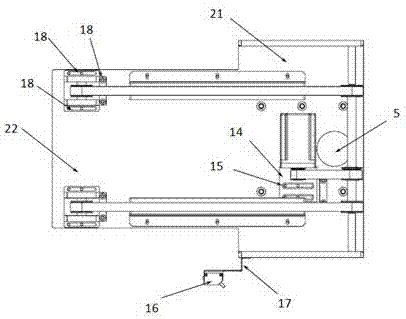

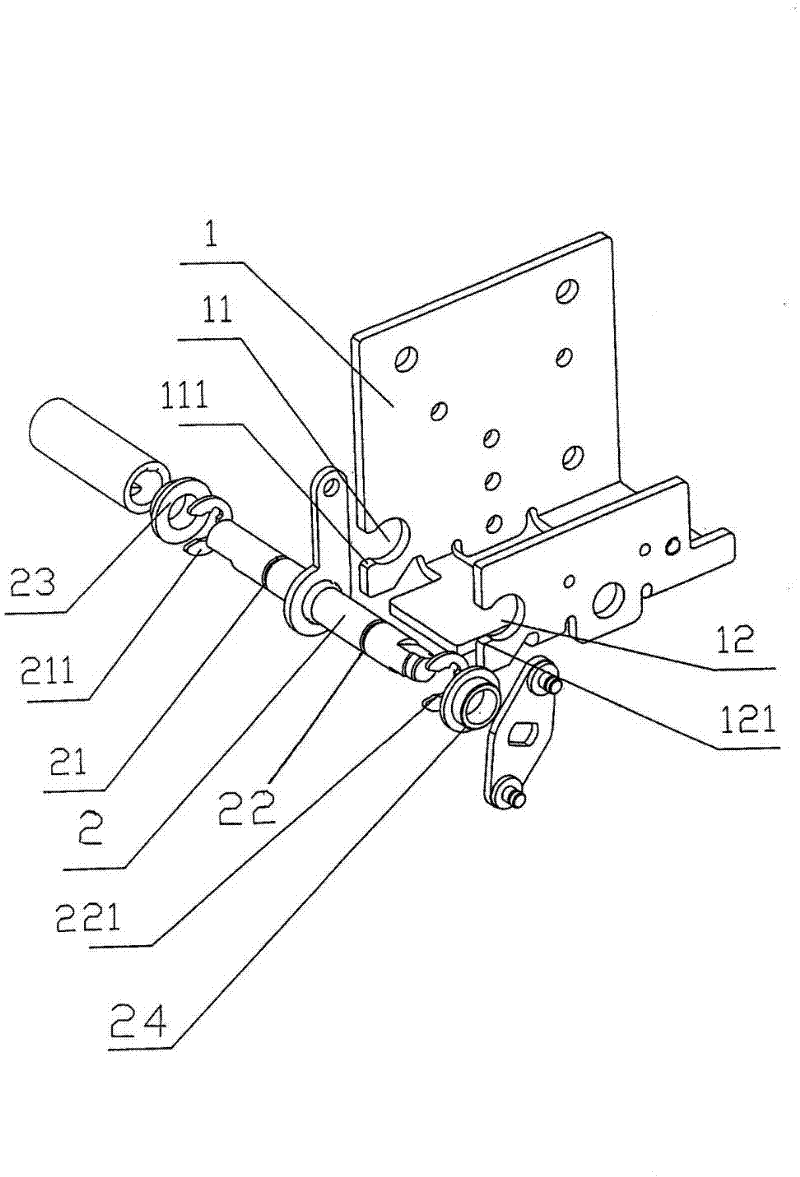

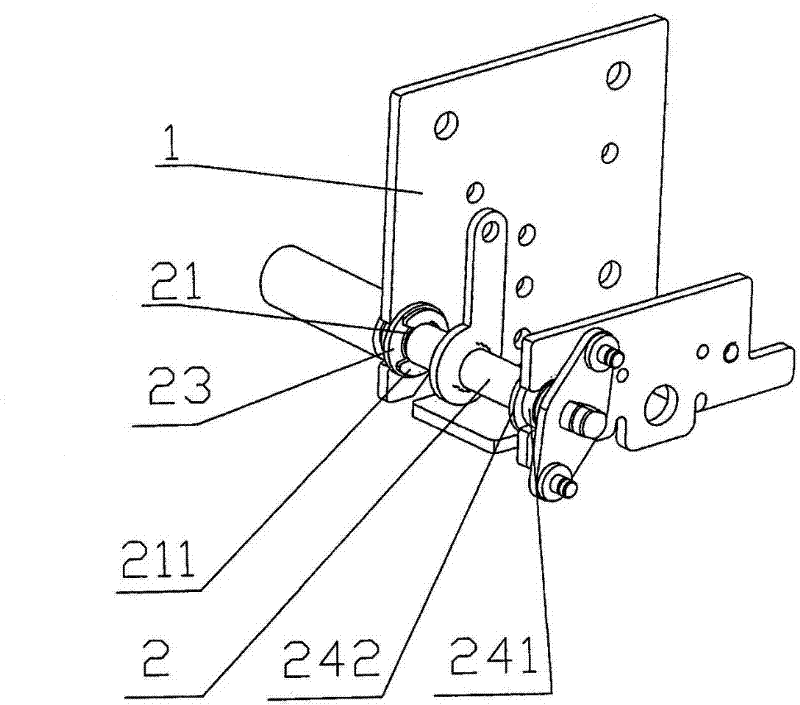

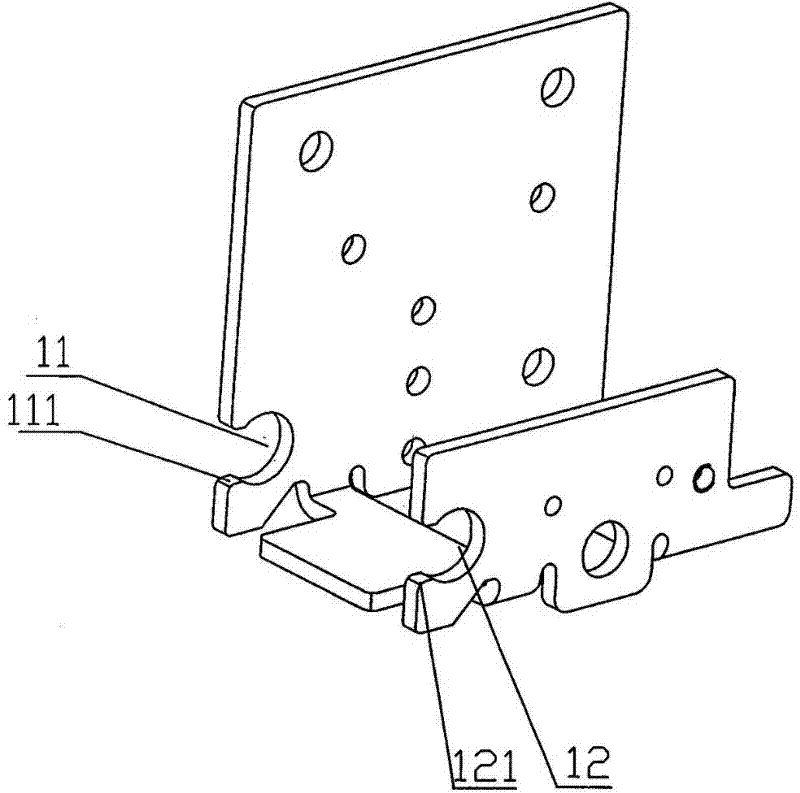

Fixture structure for machining inner cavities and joint closing surfaces of glass molds

ActiveCN103056695AEasy to settleReduce work intensityPositioning apparatusMetal-working holdersLocking mechanismEngineering

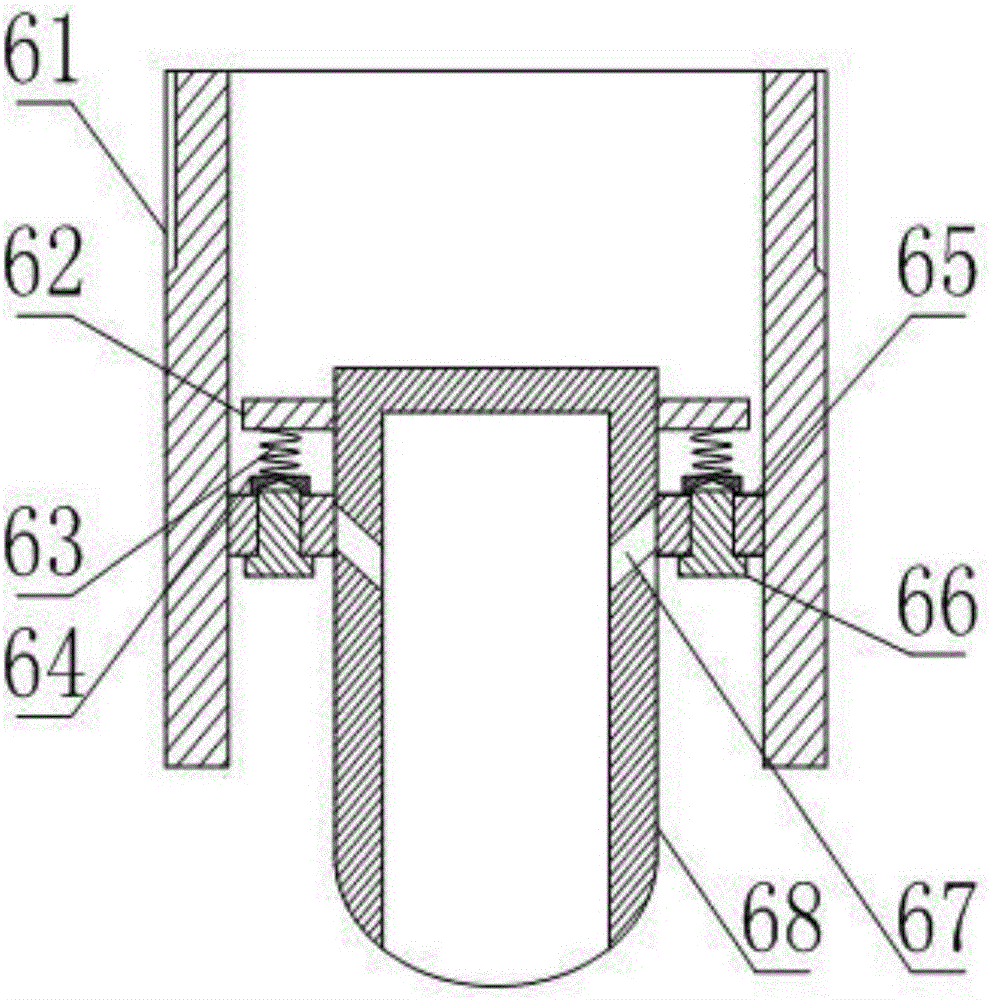

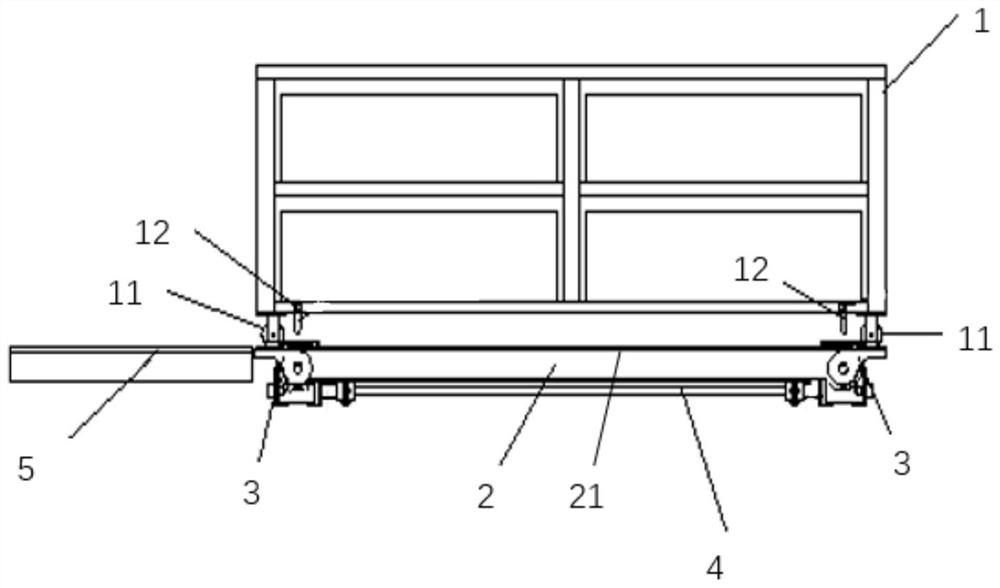

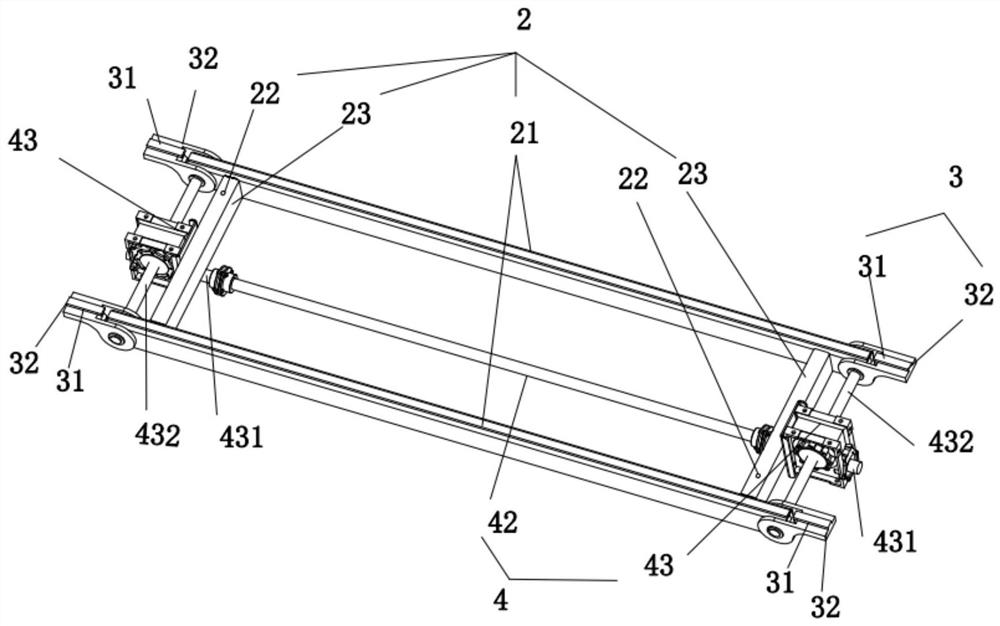

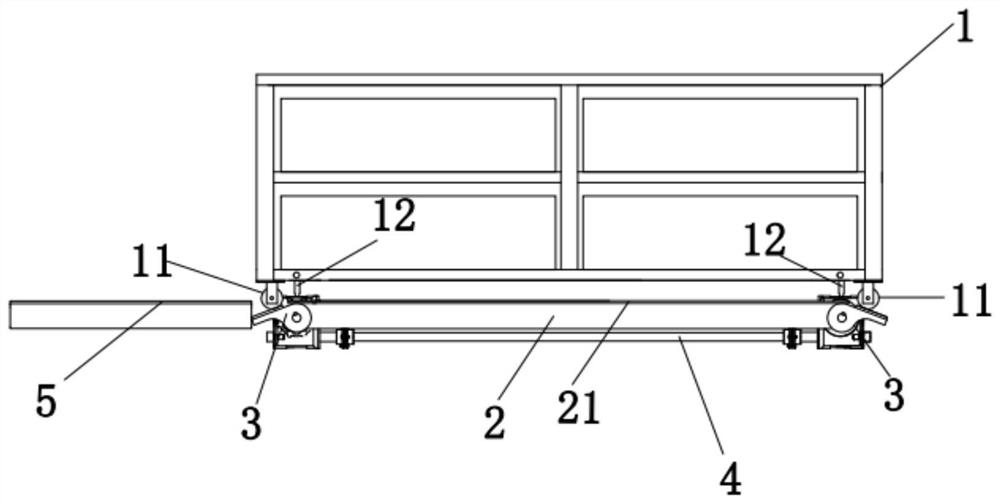

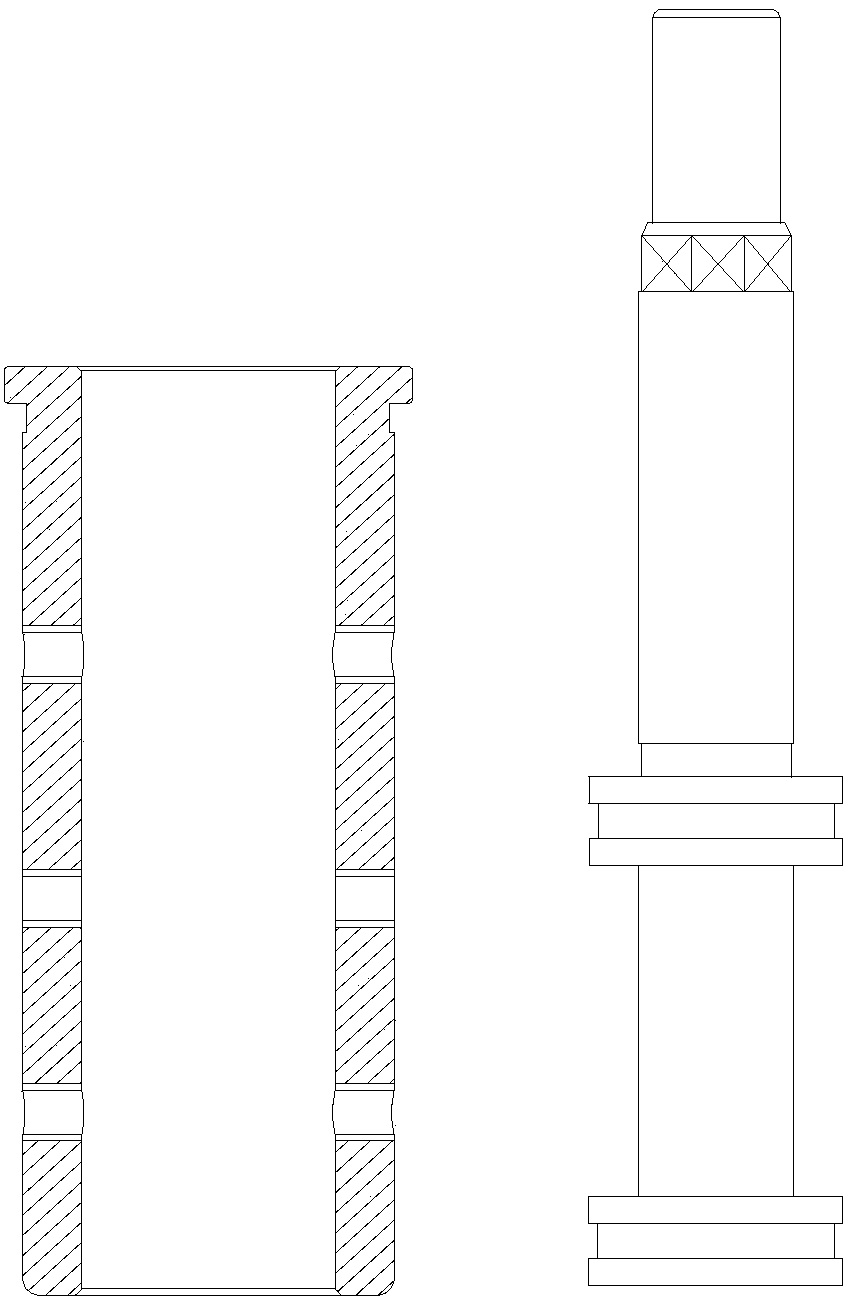

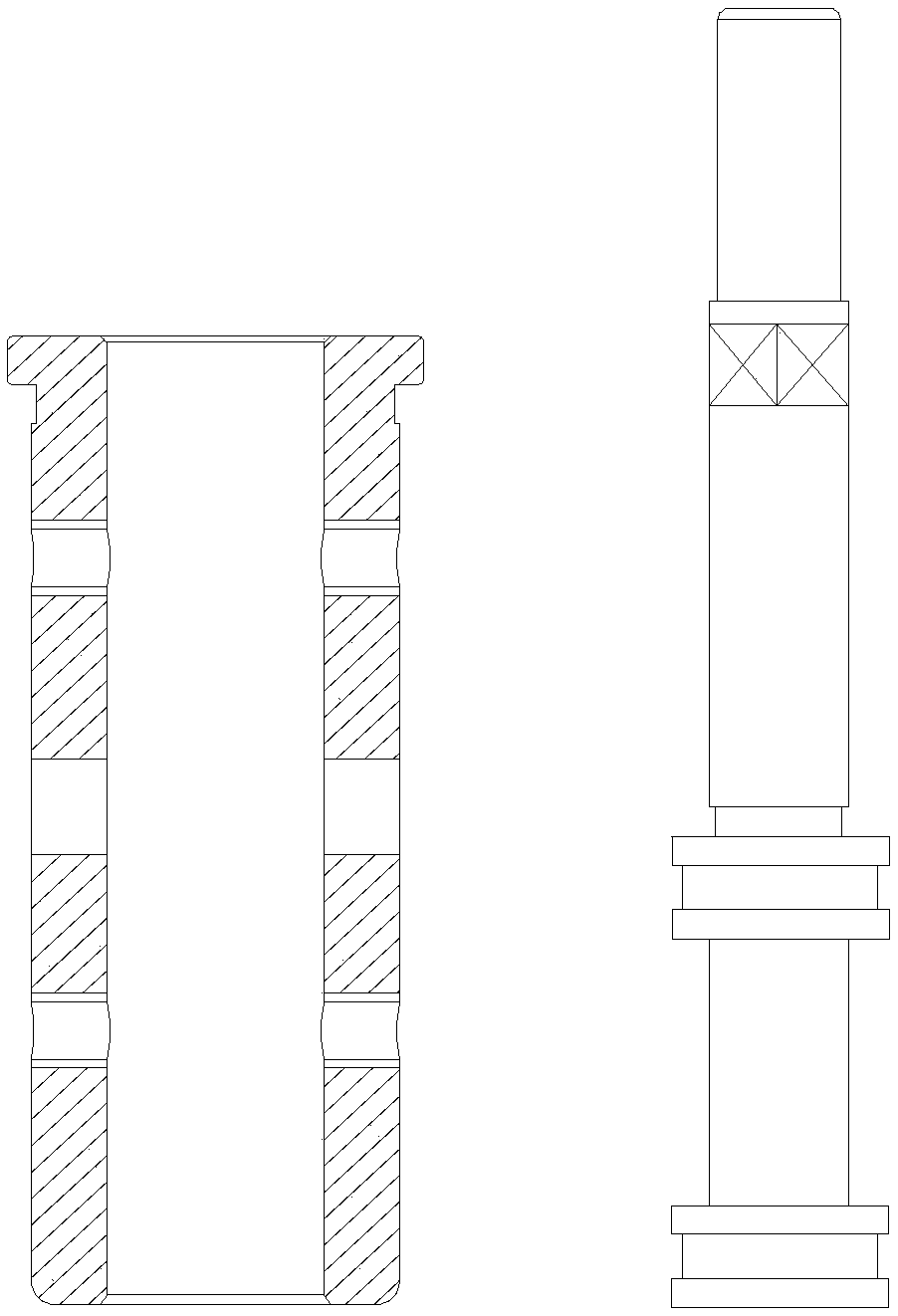

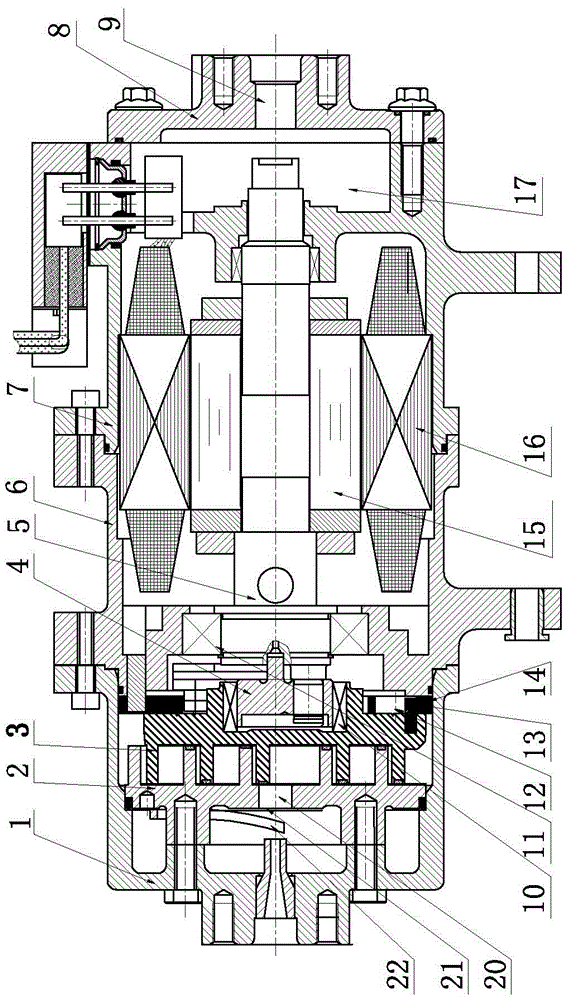

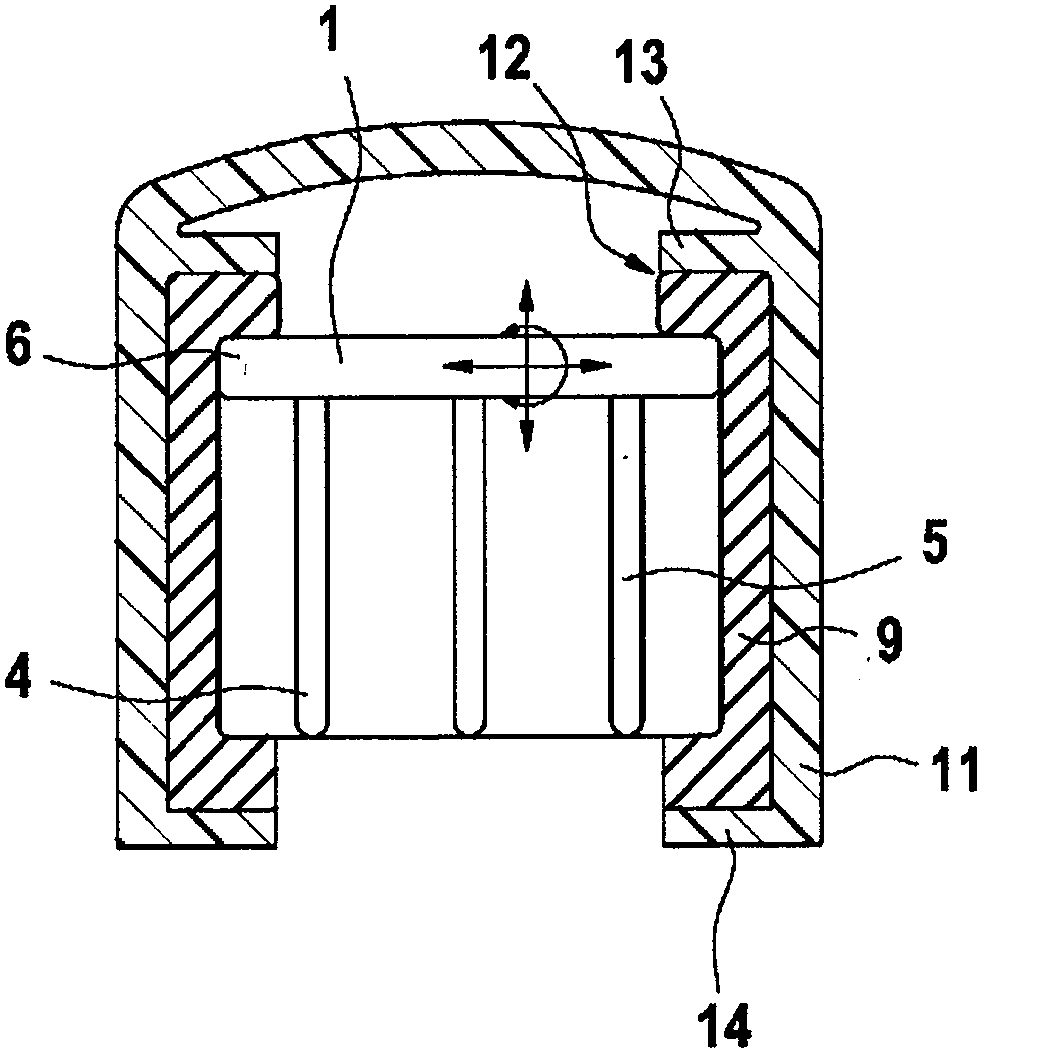

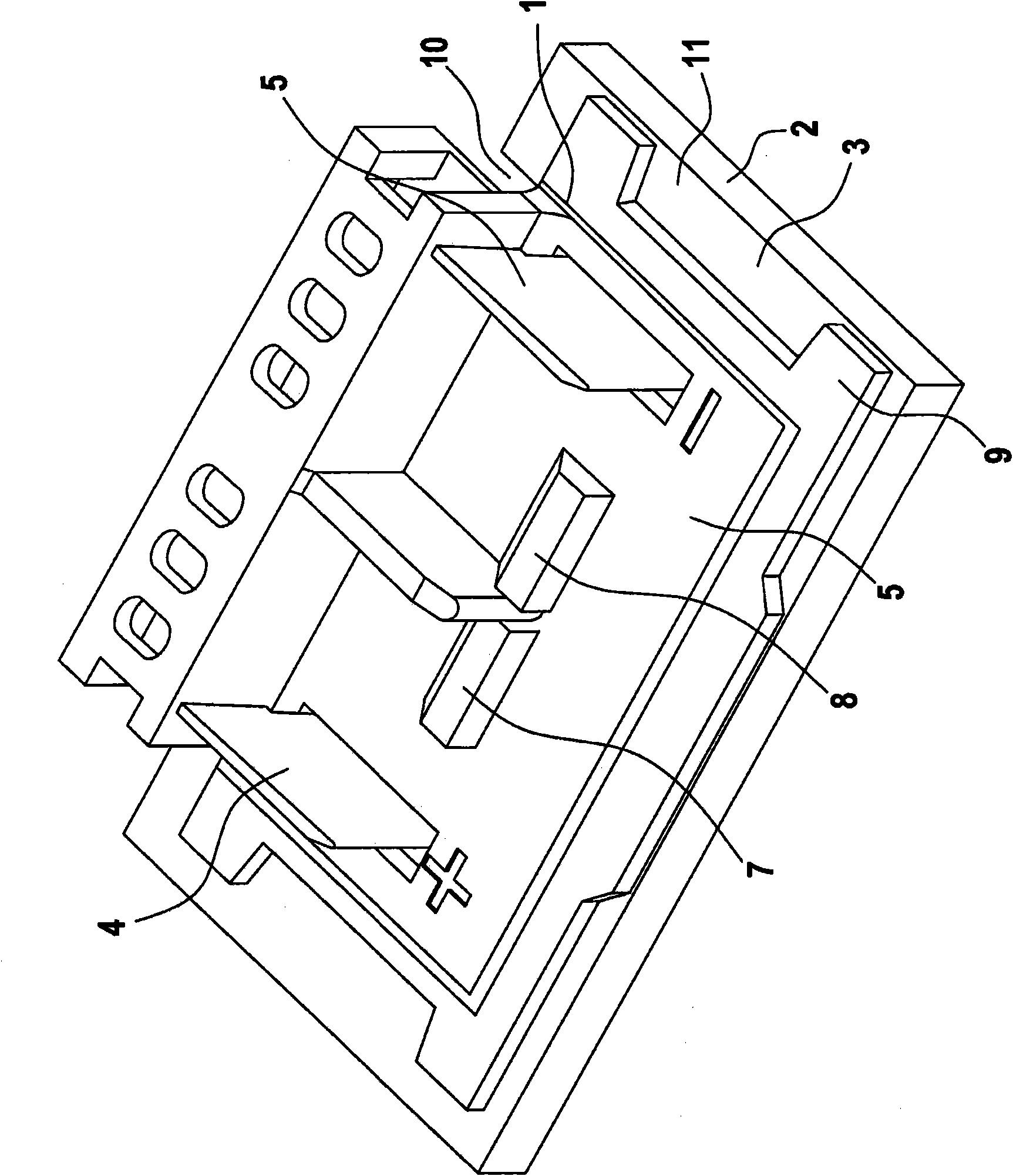

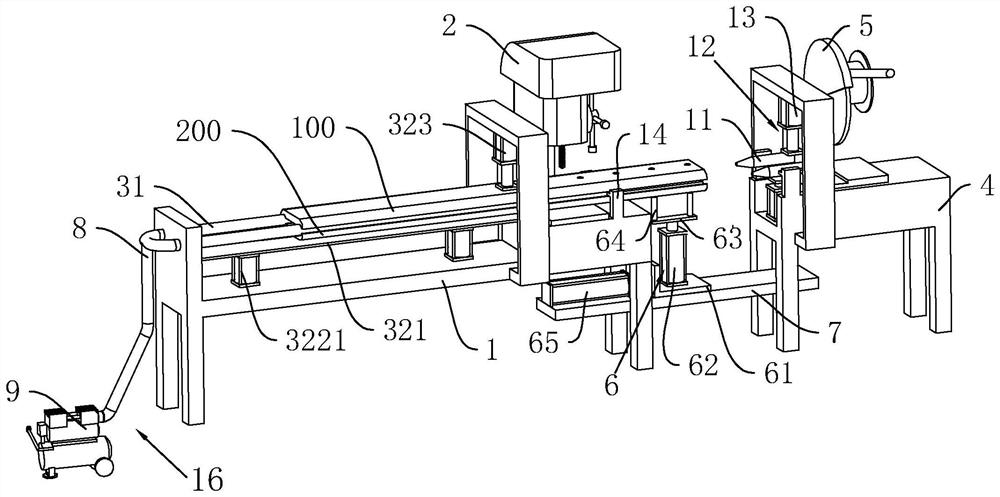

A fixture structure for machining inner cavities and joint closing surfaces of glass molds comprises a bottom seat plate, a center frame, two automatic mold supporting guide block lifting mechanisms and two automatic glass mold end surface locking mechanisms. Adjusting grooves are respectively arranged on surfaces of two ends of the bottom seat plate; adjusting grooves of mold pressing plates of the center frame are arranged on the top surface of the center frame, and the mold pressing plates of the center frame are respectively fittingly arranged on the adjusting grooves of the mold pressing plates of the center frame; the two automatic mold supporting guide block lifting mechanisms and the two automatic glass mold end surface locking mechanisms are respectively arranged at the two ends of the bottom seat plate, the automatic mold supporting guide block lifting mechanisms are positioned among the center frame and the automatic glass mold end surface locking mechanisms, a mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at one end of the bottom seat plate, and another mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at the other end of the bottom seat plate. The fixture structure has the advantages that the fixture structure is simple, and is convenient to manufacture and easy to use and maintain; the operation intensity is relieved for operators; loosening is prevented; and the machining efficiency of a machining center is improved, and the perfect matching precision between two half molds of a mold can be guaranteed.

Owner:ORI MOLD TECH SUZHOU

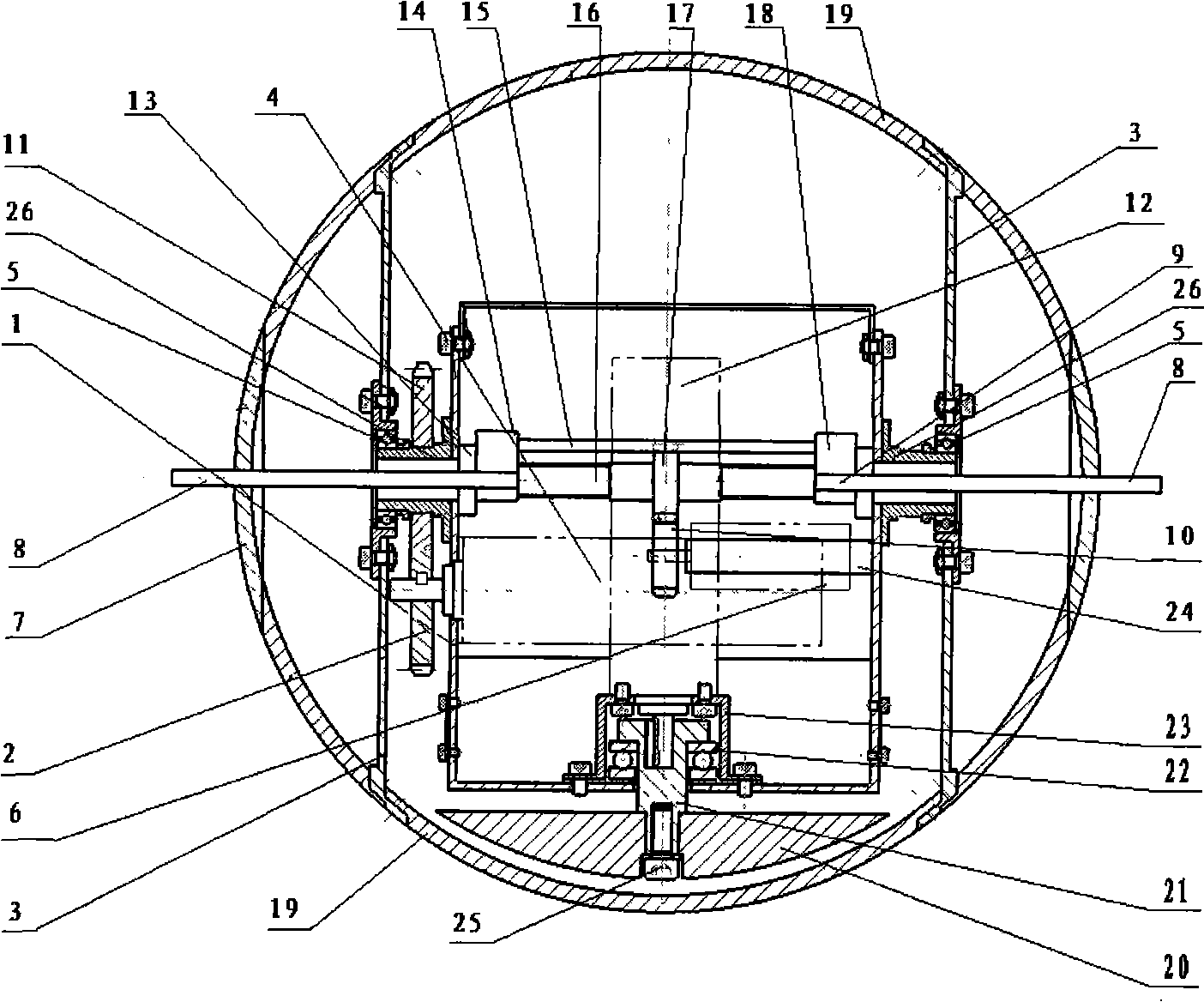

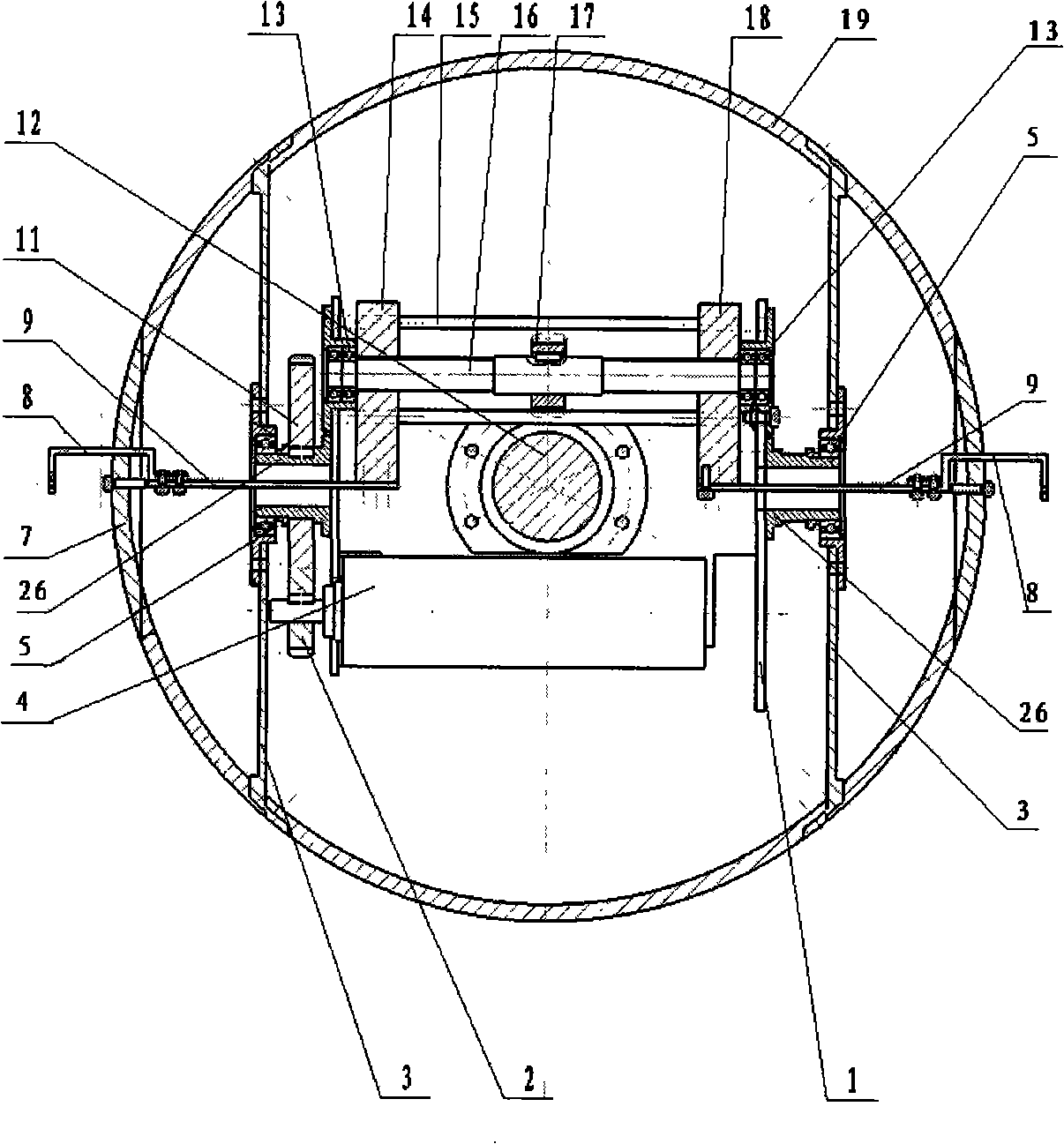

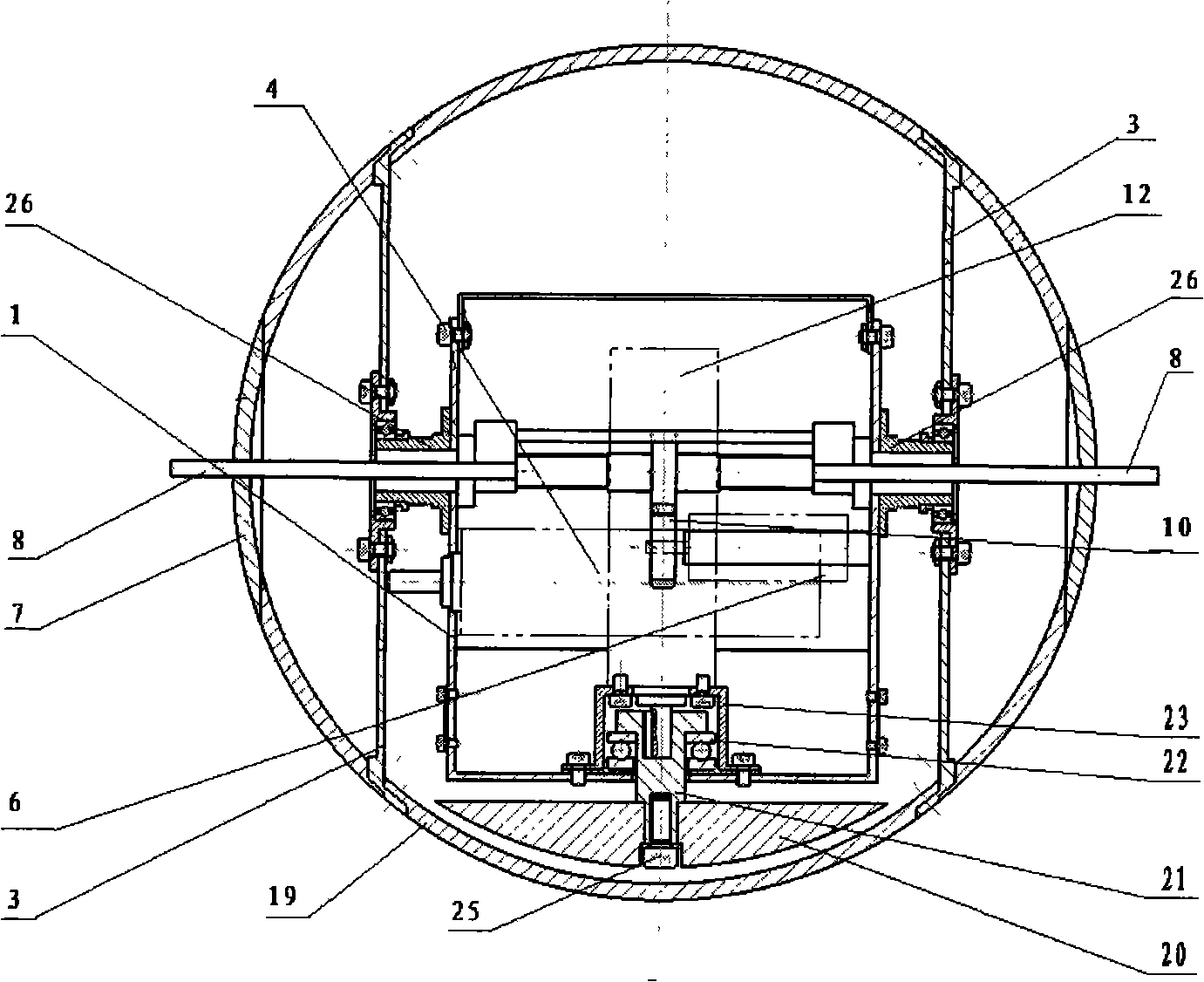

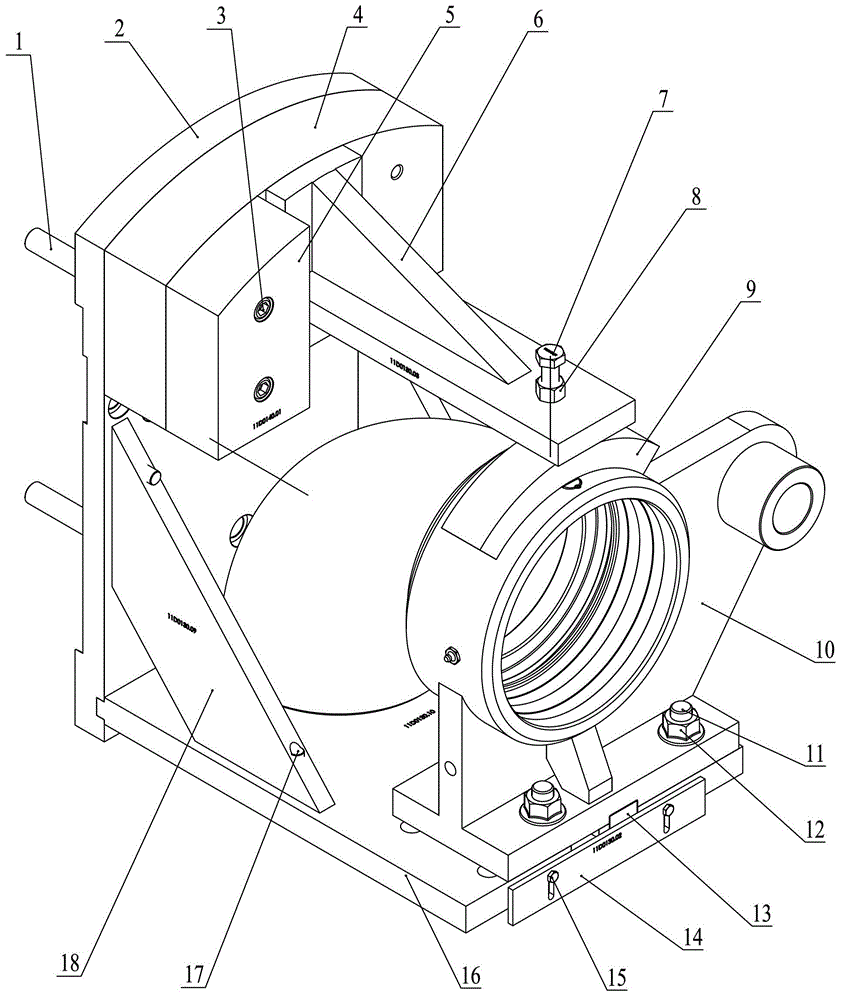

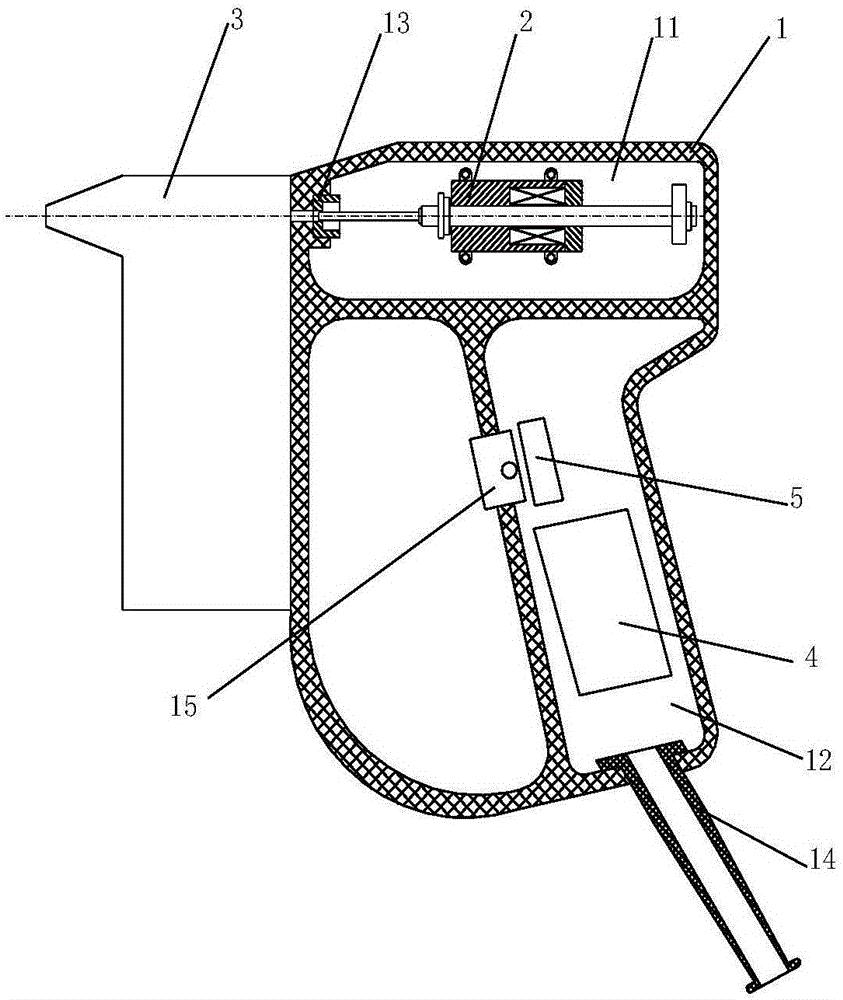

High mobility spherical detecting robot

The invention relates to a high-maneuvering spherical detection robot, which encloses a movement mechanism and a control device, etc., into a spherical shell and realizes the movement of the whole robot through the barycenter offset and the angular momentum conservation principle. The movement mechanism mainly comprises a support frame, a connection disk, a straight-line drive mechanism, a pivot steering drive mechanism, a telescoping mechanism, etc. The straight-line drive mechanism mainly comprises a drive motor, a gear transmission unit, an executive part, etc., which takes advantage of the barycenter offset to realize the straight-line movement of the spherical robot. The pivot steering drive mechanism comprises a drive motor and an executive mechanism, which takes advantage of the angular momentum conservation principle to realize the pivot steering movement of the spherical robot. The combination of straight-line and steering movements can realize the movement of the high-maneuvering spherical detection robot in any orientation. The telescoping mechanism comprises a drive motor, a screw mechanism, etc., which are used for realize the purpose that cameras at both ends protrude out of and retract into a sphere shell. The spherical robot not only provides a steady platform for installing cameras, but also realizes the pivot steering with flexible movement and strong maneuverability, and the spherical robot can be used for a plurality of tasks such as high toxic gas detection, field environment observation, and planetary exploration, etc.

Owner:战强

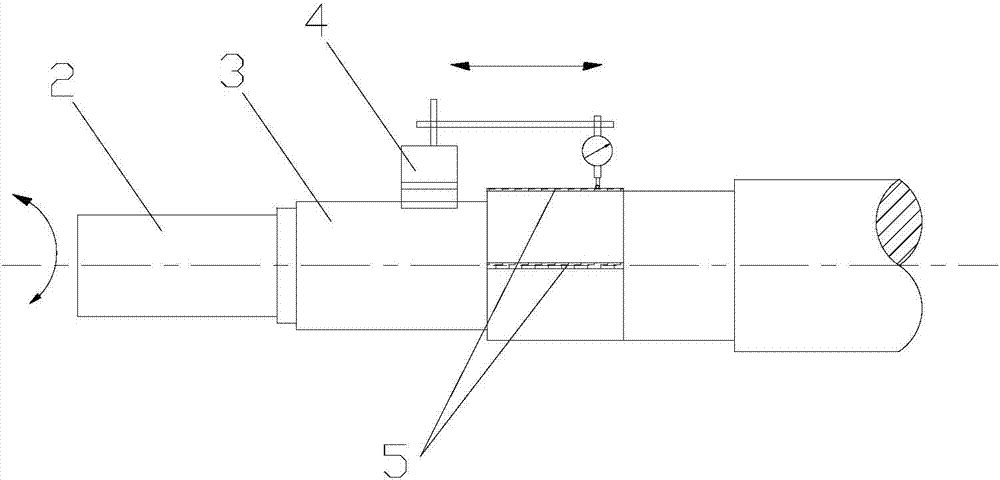

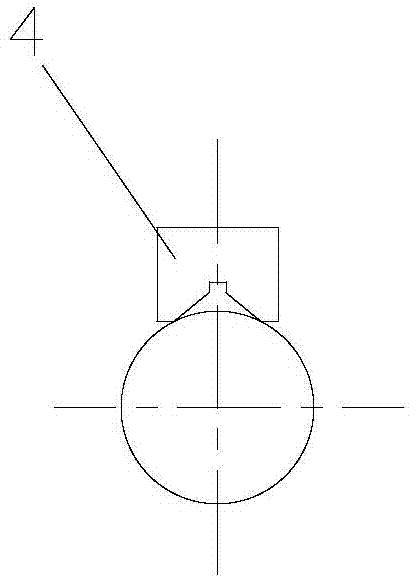

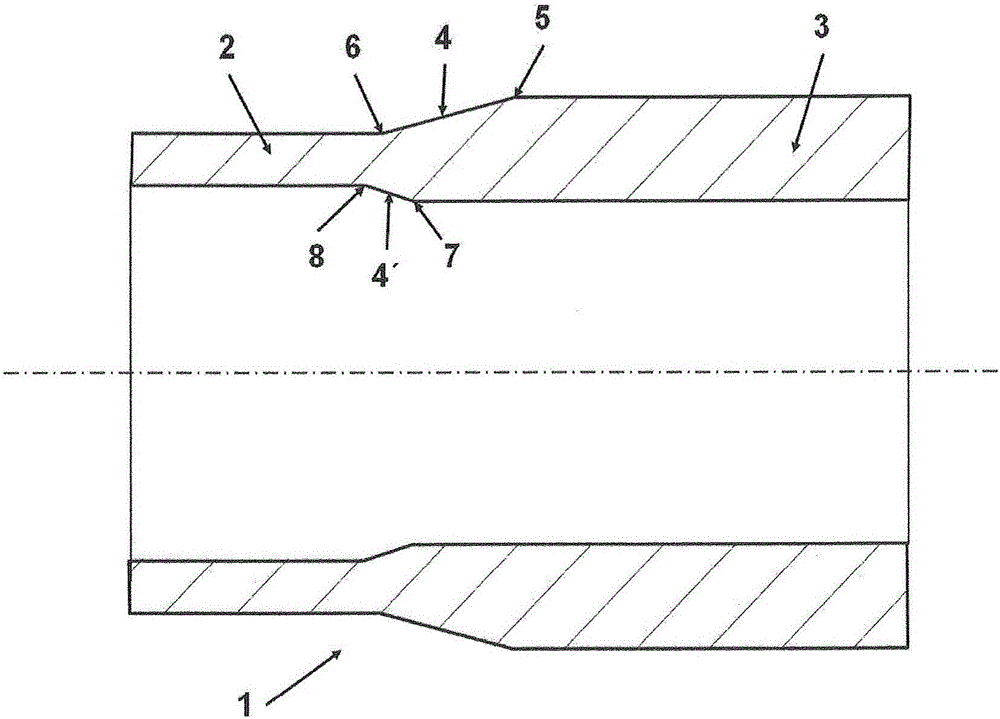

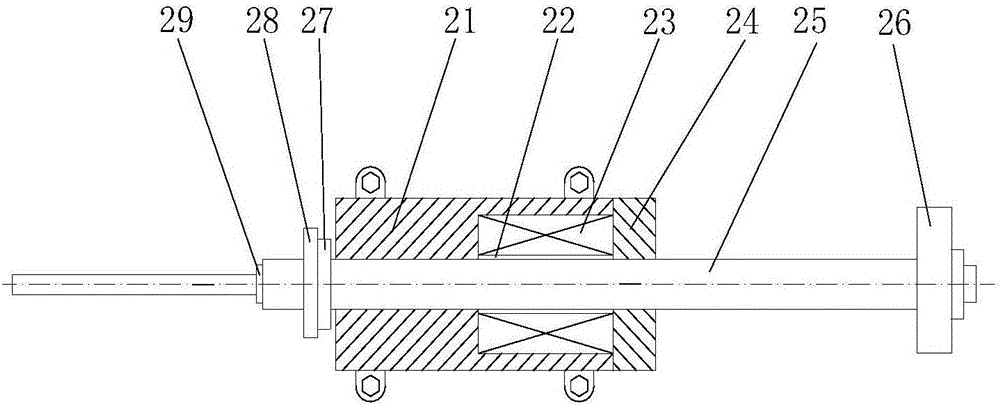

Online shaft neck repairing method

The invention relates to an online shaft neck repairing method. The online shaft neck repairing method includes: grinding a worn shaft neck coarsely; welding weld ribs; finishing the weld ribs; machining a bush; mounting the bush and replacing a bearing sequentially on the shaft neck provided with the weld ribs and completing repairing after post processing. By the method, the shaft neck at the cooperative positions of two ends of a shaft and the inner ring of the bearing can be repaired online, repairing time and cost can be favorably saved, and production can be ensured to run smoothly.

Owner:NANJING MEISHAN METALLURGY DEV +1

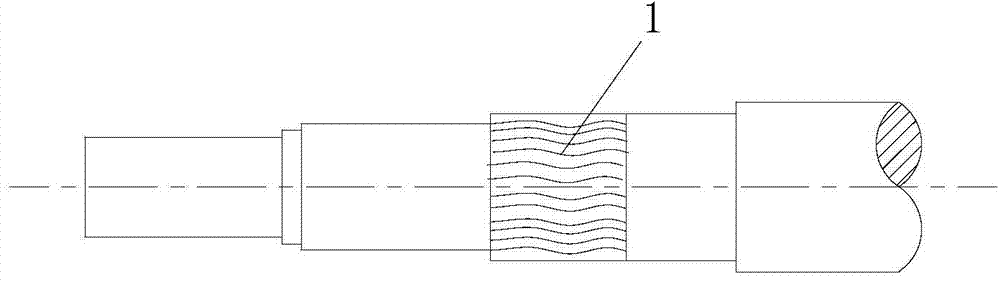

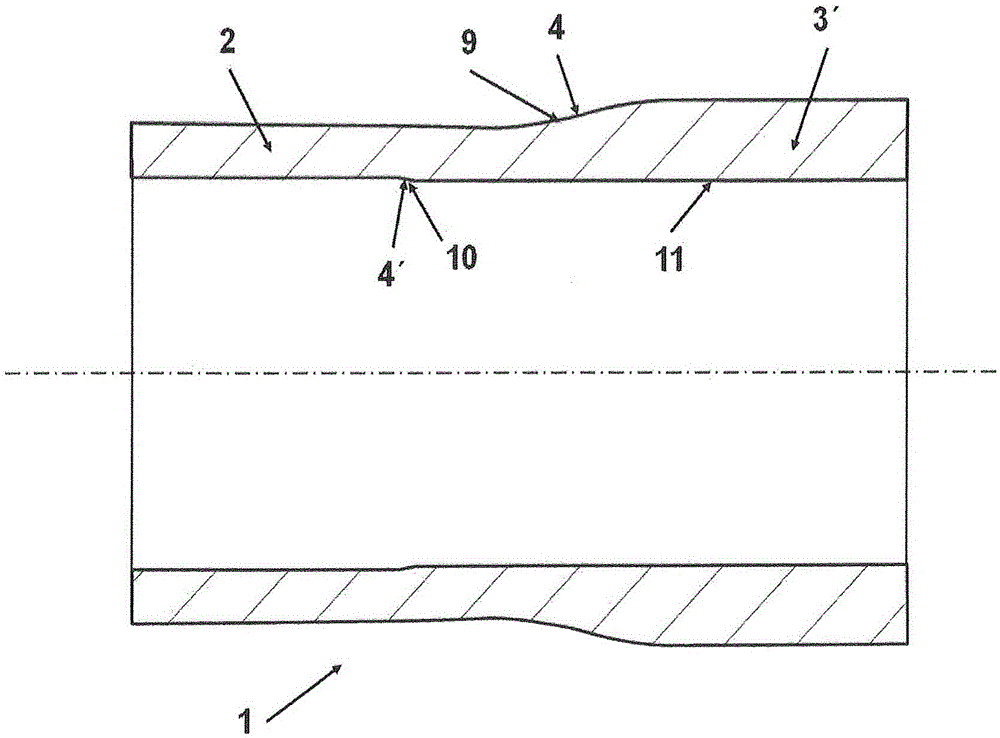

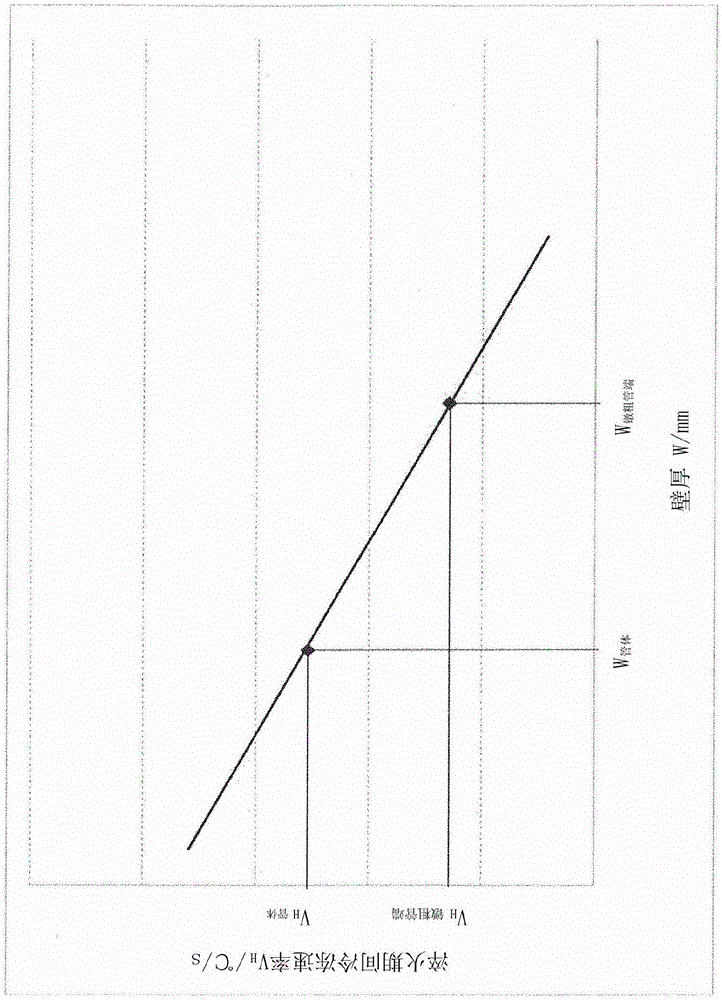

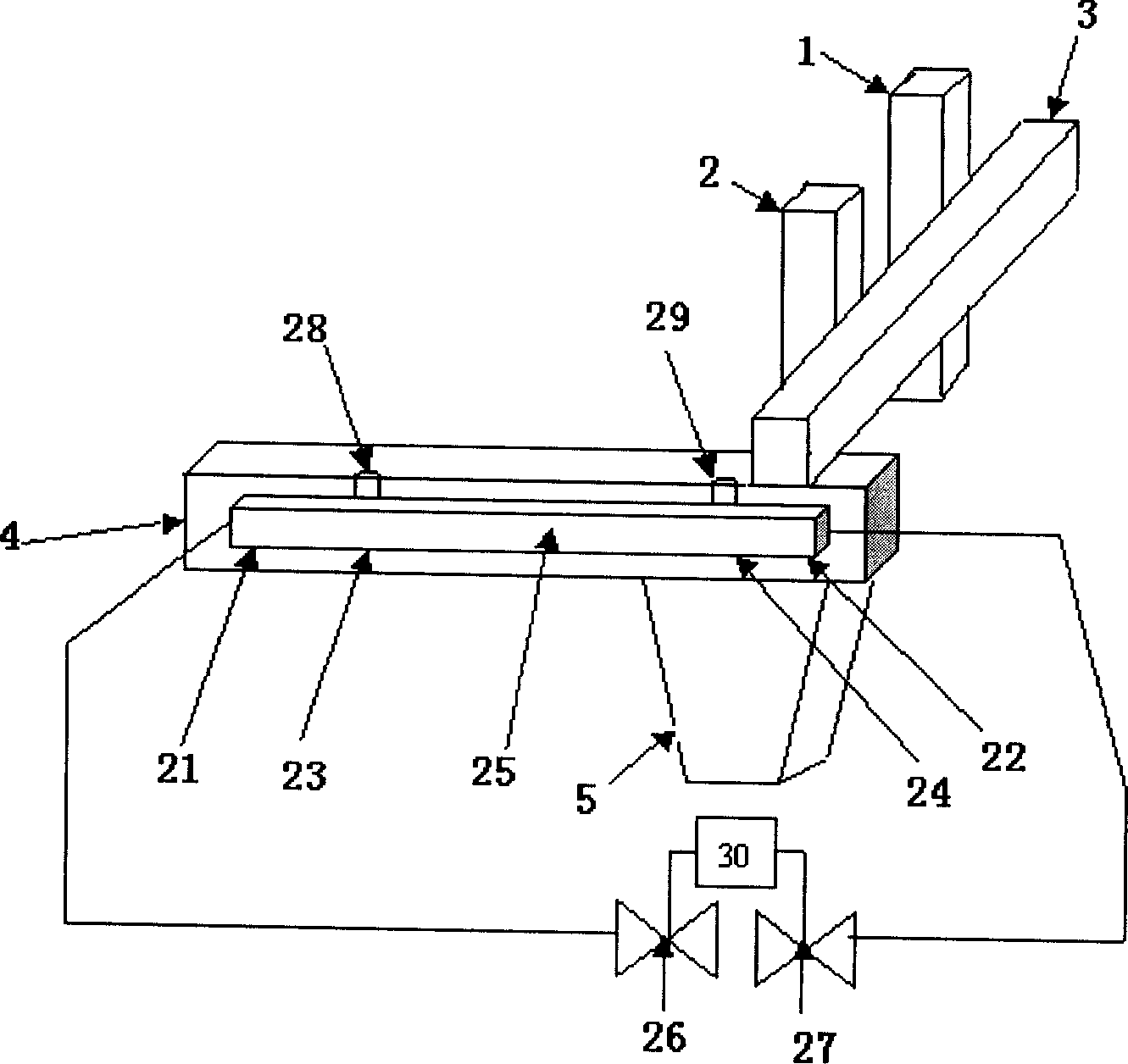

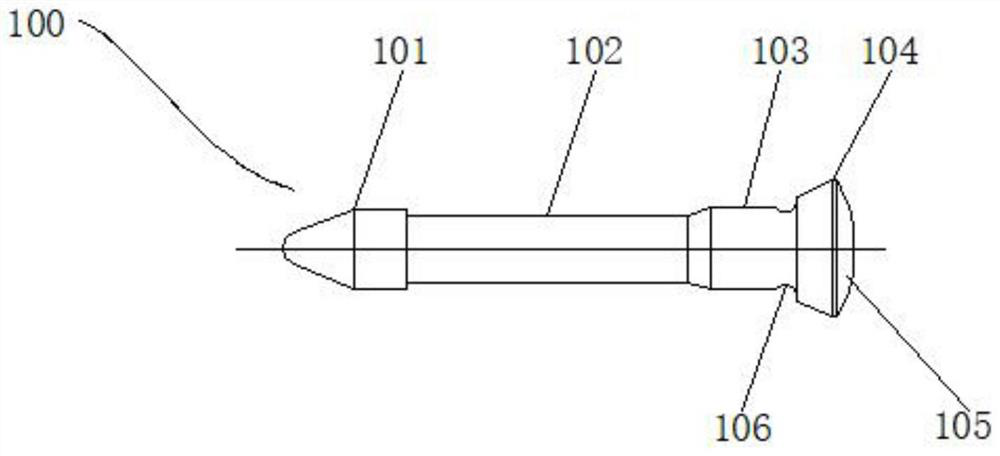

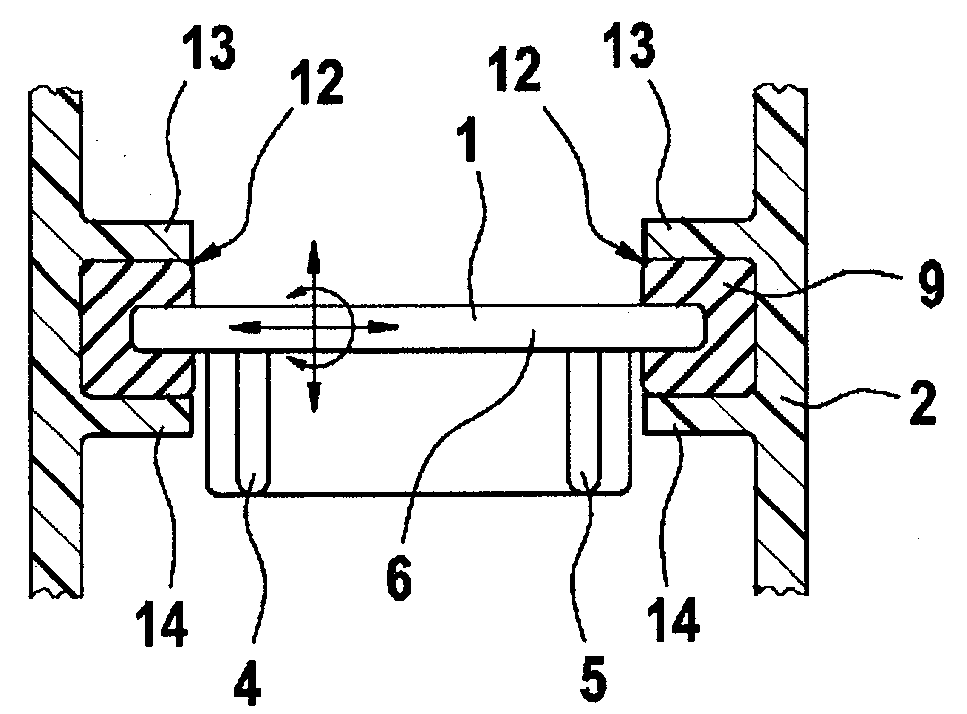

Method for producing hot-rolled seamless pipes from transformable steel, in particular for pipelines for deep-water applications, and corresponding pipes

InactiveCN106232837AImprove solderabilityGood matching precisionFurnace typesQuenching agentsUltimate tensile strengthMaterials science

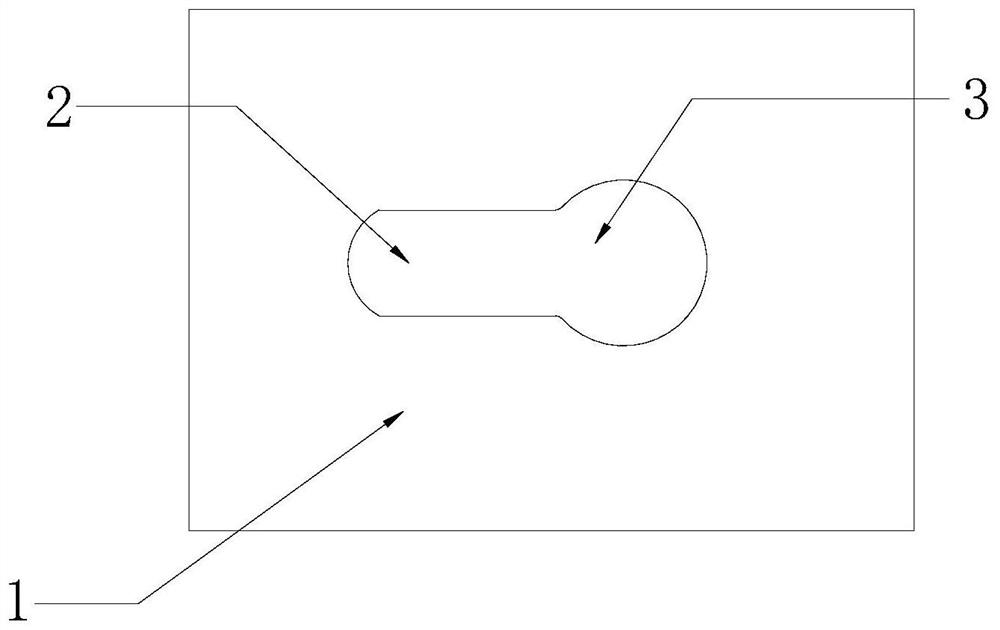

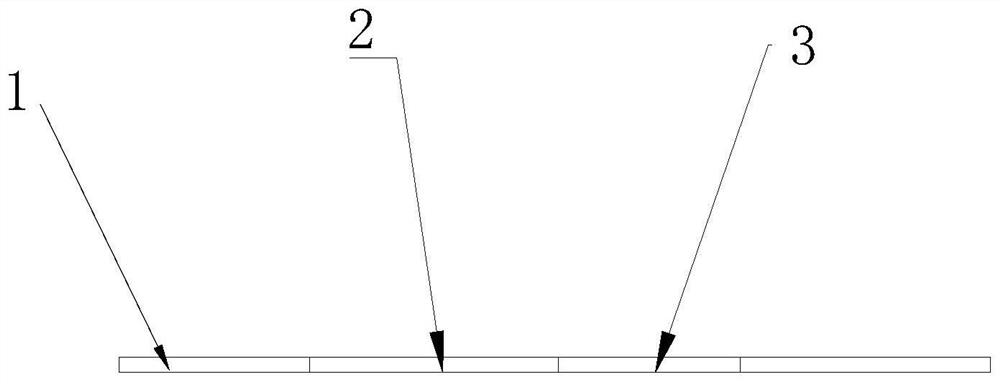

The invention relates to a method for producing hot-rolled seamless pipes (1) from transformable steel, in particular for pipelines for deep-water applications. The pipe ends (3) are hot-upsetted in order to achieve a thickened wall portion after a final rolling process of the pipes (1). The aim of the invention is to produce pipes with excellent fatigue, corrosion, and welding properties. This is achieved in that a pre-selected ratio between a wall thickness of the pipe end (3) and a wall thickness of a wall body (2) adjoining the pipe end (3) is set by the hot-upsetting process such that a pipe (1) is achieved with a pipe end (3) which has a lower strength than the pipe body (2) after a uniform tempering process of the entire pipe (1) following the hot-upsetting process by using a previously ascertained wall thickness-dependent cooling rate during the tempering process.

Owner:VALLOUREC DEUT

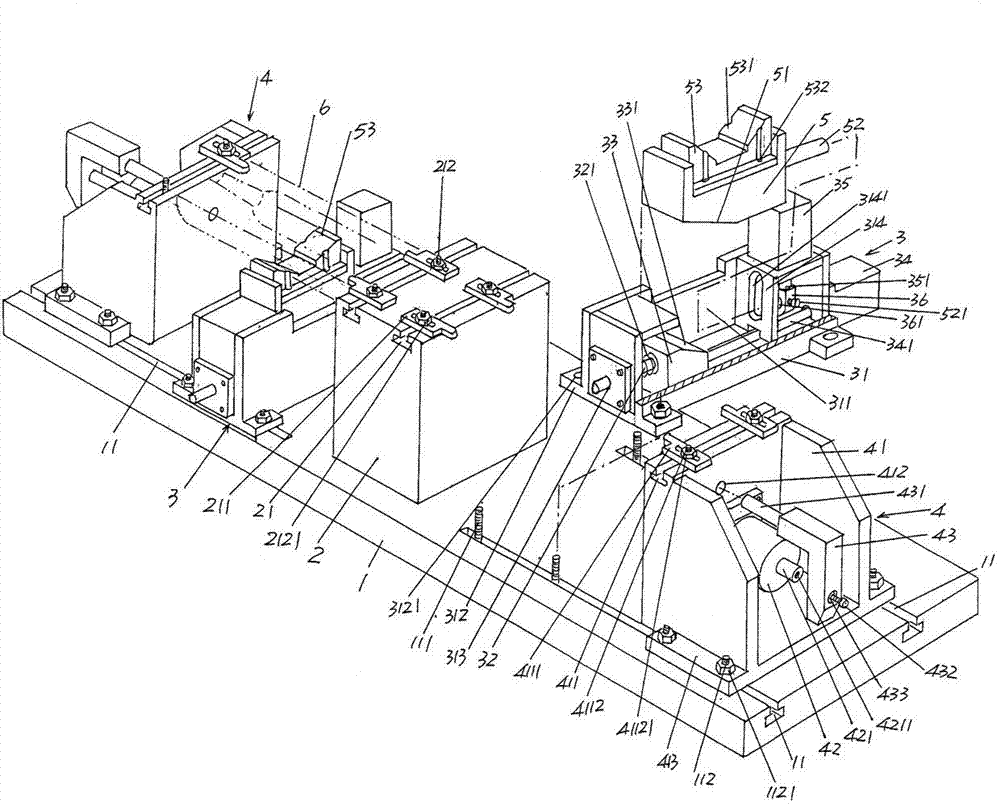

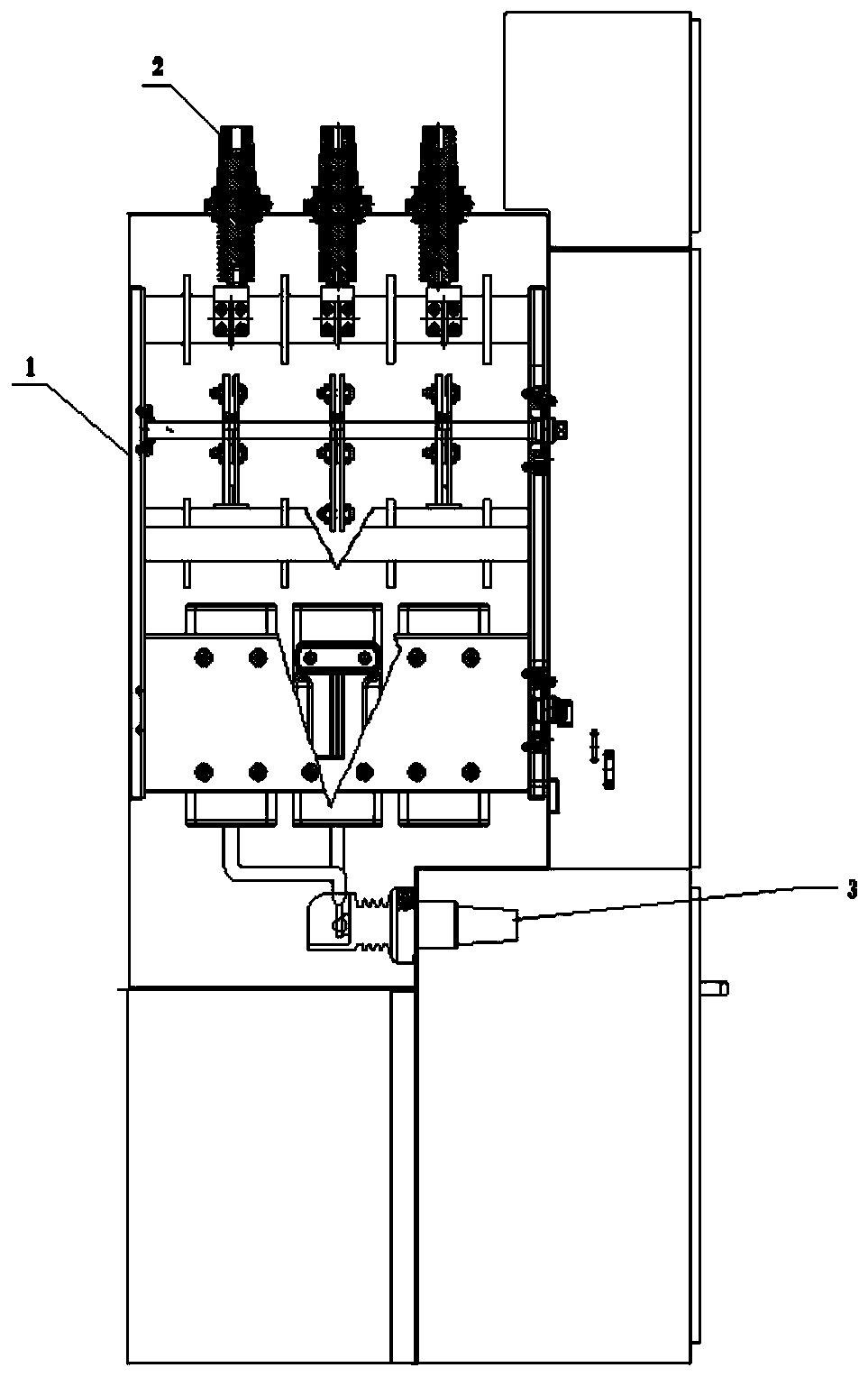

Fixture structure for machining inner cavities and joint closing surfaces of glass molds

ActiveCN103056695BEasy to settleReduce work intensityPositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

A fixture structure for machining inner cavities and joint closing surfaces of glass molds comprises a bottom seat plate, a center frame, two automatic mold supporting guide block lifting mechanisms and two automatic glass mold end surface locking mechanisms. Adjusting grooves are respectively arranged on surfaces of two ends of the bottom seat plate; adjusting grooves of mold pressing plates of the center frame are arranged on the top surface of the center frame, and the mold pressing plates of the center frame are respectively fittingly arranged on the adjusting grooves of the mold pressing plates of the center frame; the two automatic mold supporting guide block lifting mechanisms and the two automatic glass mold end surface locking mechanisms are respectively arranged at the two ends of the bottom seat plate, the automatic mold supporting guide block lifting mechanisms are positioned among the center frame and the automatic glass mold end surface locking mechanisms, a mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at one end of the bottom seat plate, and another mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at the other end of the bottom seat plate. The fixture structure has the advantages that the fixture structure is simple, and is convenient to manufacture and easy to use and maintain; the operation intensity is relieved for operators; loosening is prevented; and the machining efficiency of a machining center is improved, and the perfect matching precision between two half molds of a mold can be guaranteed.

Owner:ORI MOLD TECH SUZHOU

Specially-shaped body annular groove machining mechanism

ActiveCN102909574ATurn aroundSimple and flexible structurePositioning apparatusMaintainance and safety accessoriesMachine partsEngineering

The invention relates to a specially-shaped body annular groove machining mechanism, which is characterized in that a vertical plate is connected with a soleplate into a whole, the vertical plate is provided with a connecting bolt which is in fitting connection with a numerical-control lathe rotary main shaft chuck to be locked; a specially-shaped body to be machined is tightened onto the soleplate through a tightening screw and a hexagonal nut, and the soleplate is provided with a positioning key which enables the specially-shaped body to be machined to rotate concentrically with the numerical-control lathe rotary main shaft; and a pressure plate is installed on the upper part of the vertical plate, the front end of the pressure plate is provided with a pressure block for compressing the specially-shaped body to be machined through a compression screw, the pressure block can be compressed onto the specially-shaped body to be machined by screwing the compression screw, and the compression screw is provided with a locking nut. A machined part of the specially-shaped body can be rotated through rapid installation, clamping and positioning, and an ordinary tool is used for cutting a hole and an annular groove to be machined of the specially-shaped body, so that the auxiliary time is reduced, the machining efficiency is improved, and the investment cost of the equipment and forming tool can be greatly reduced.

Owner:TENGXUAN TECH

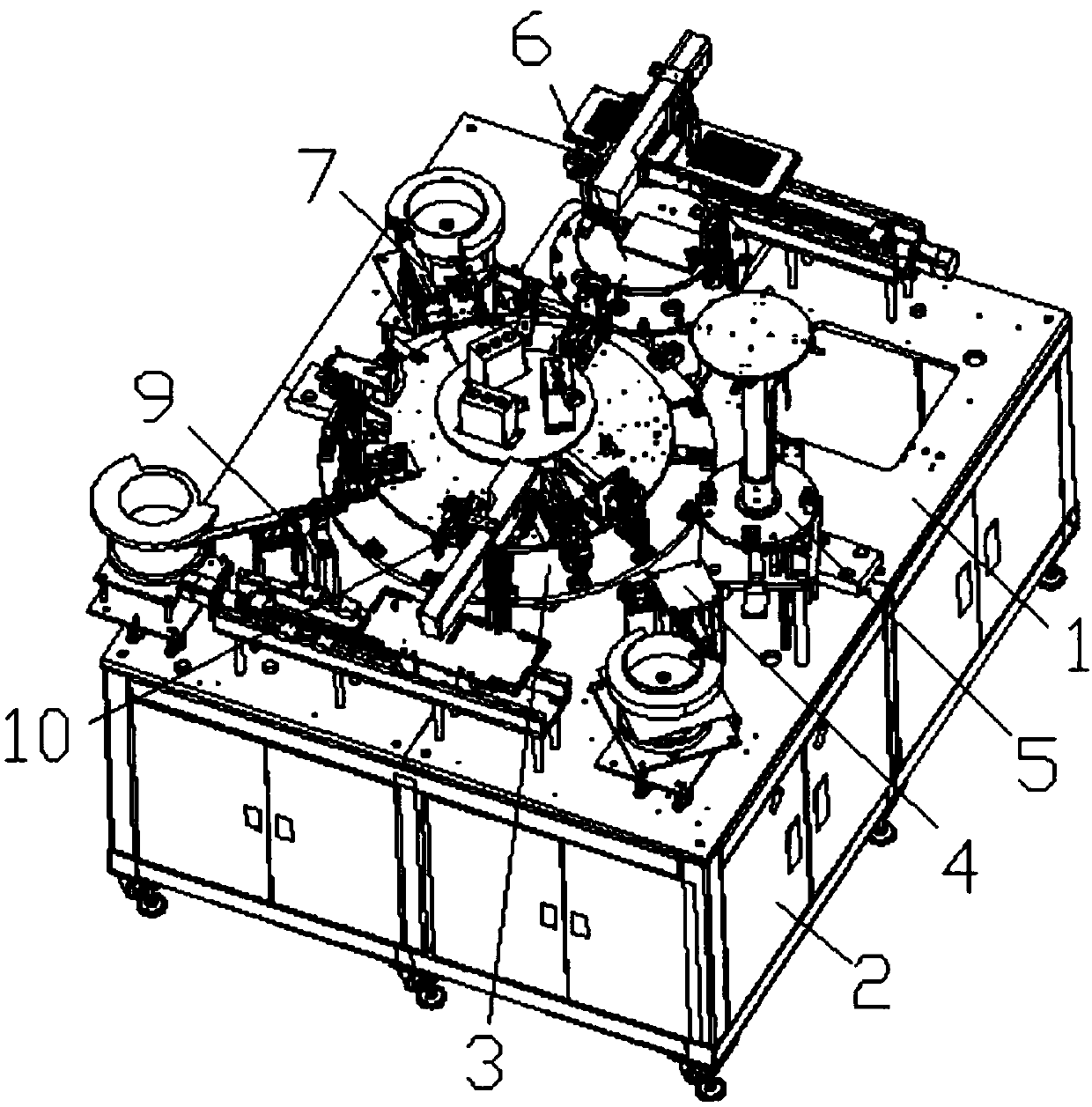

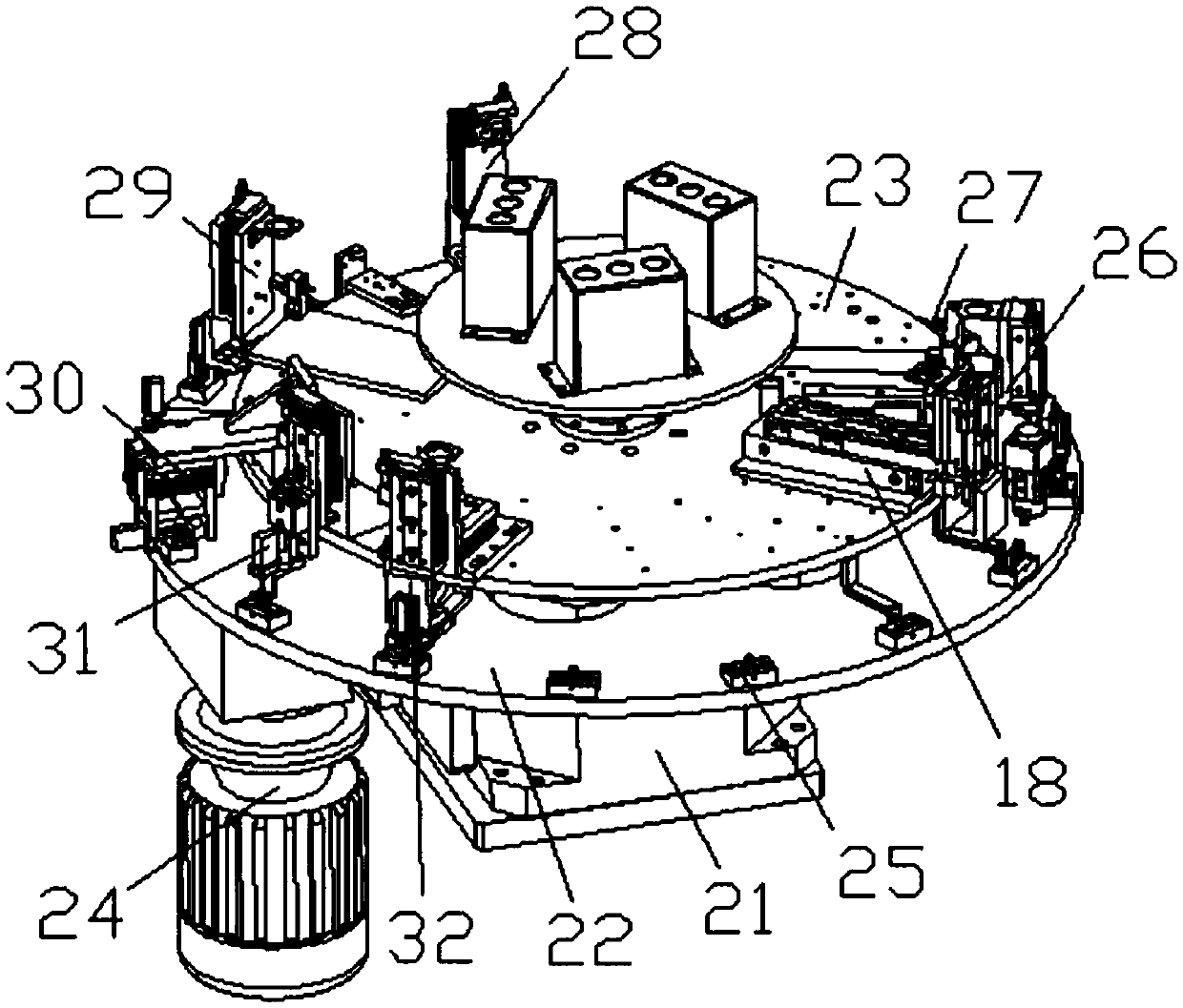

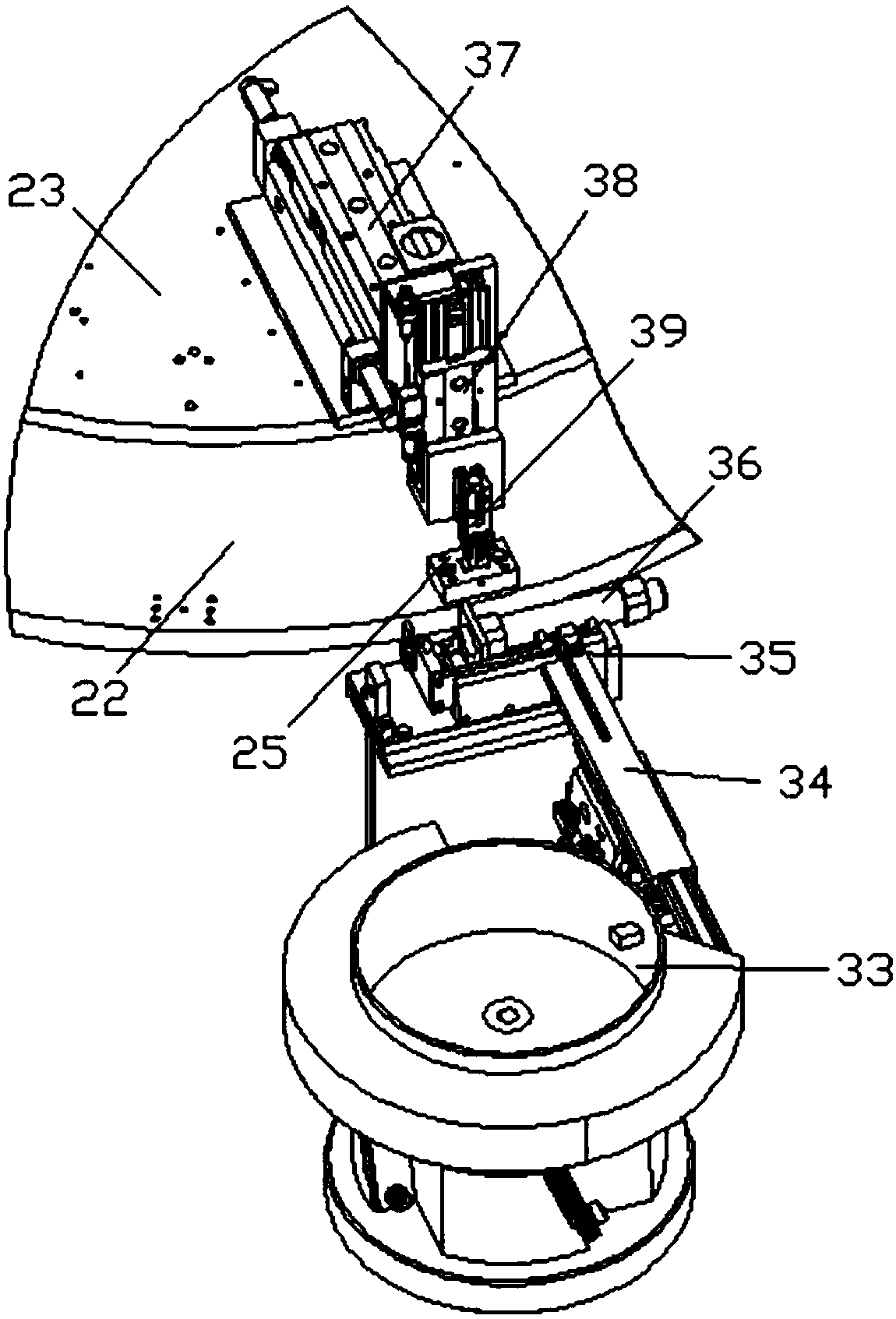

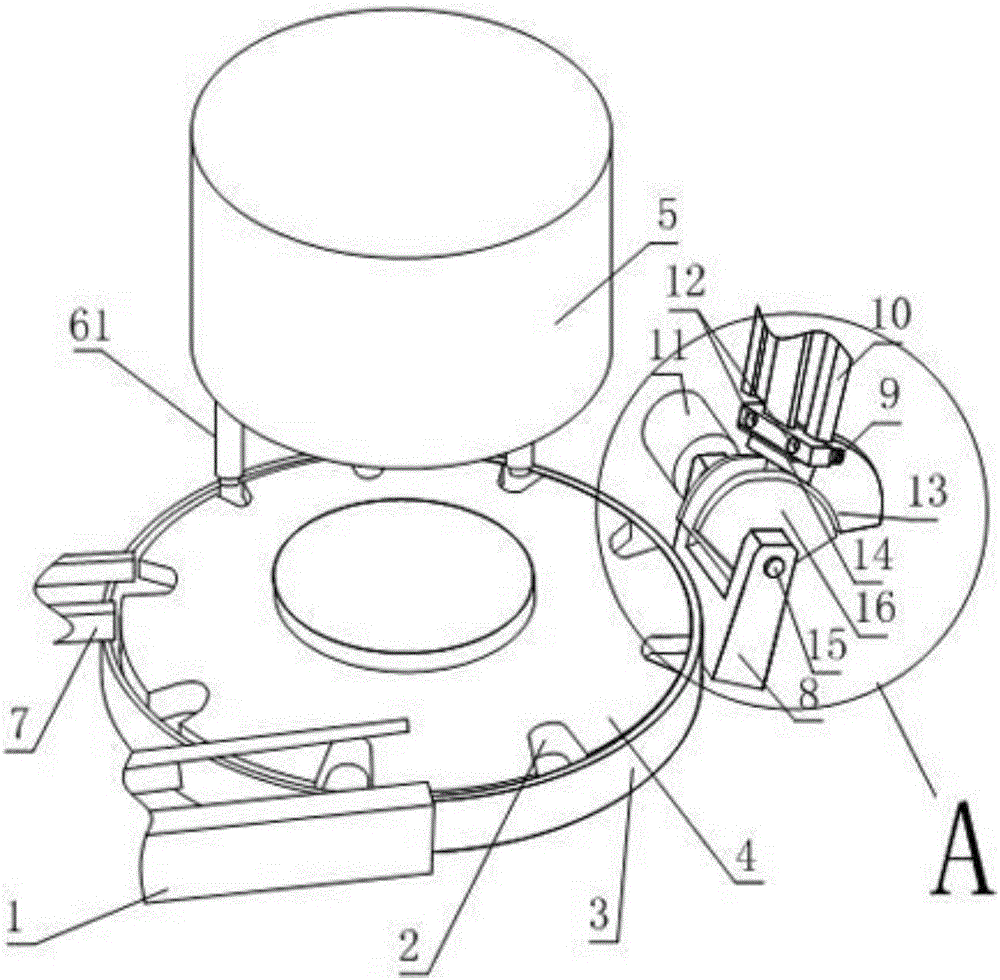

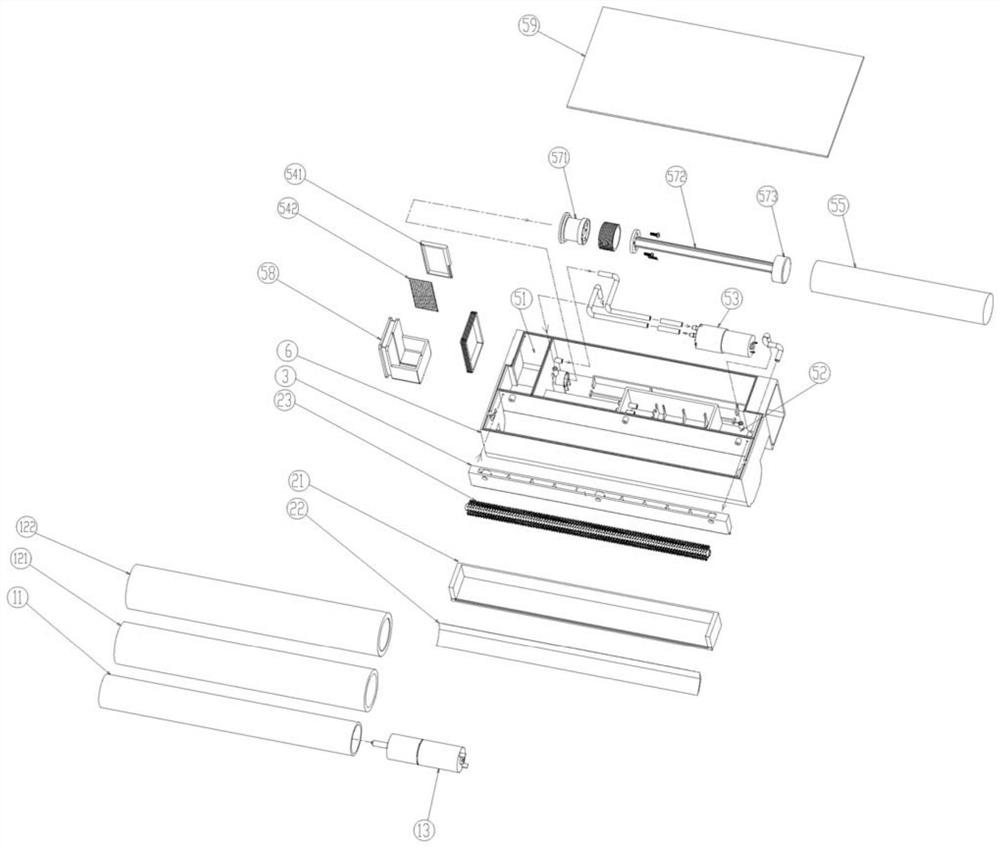

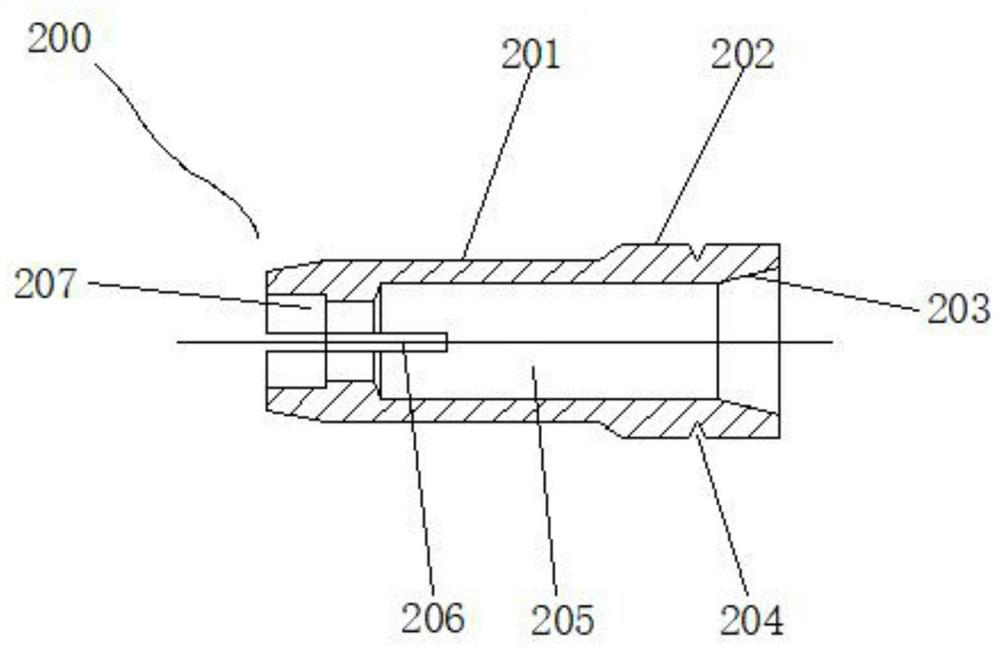

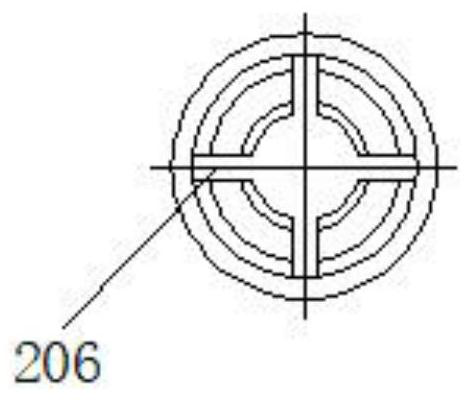

Full-automatic optical fiber head assembling machine capable of conducting insertion core assembling

ActiveCN107553130AImprove processing efficiencyTighten to achieveAssembly machinesDistribution controlButt joint

The invention relates to a full-automatic optical fiber head assembling machine capable of conducting insertion core assembling. The full-automatic optical fiber head assembling machine comprises a rack and a power distribution control box. The rack is provided with a rotary disc assembly, a base assembling mechanism, a spring assembling mechanism, a shell assembling mechanism, a cover sealing assembling mechanism and a discharging device, wherein the base assembling mechanism, the spring assembling mechanism, the shell assembling mechanism, the cover sealing assembling mechanism and the discharging device are matched with the rotary disc mechanism. A rotary disc rack comprises an assembling rotary disc installation base arranged on the rack, an assembling rotary disc and an assembling fixing disc which are concentric are installed on the assembling rotary disc installation base, the assembling rotary disc is matched with an assembling rotary disc motor, and assembling carriers are evenly arranged at the outer portion of the assembling rotary disc in an annular shape. An insertion core assembling mechanism is arranged between the spring assembling mechanism and the shell assemblingmechanism. By means of the full-automatic optical fiber head assembling machine capable of conducting insertion core assembling, an insertion core assembling rotary disc can be matched with an insertion core assembling part to synchronously machine the insertion core while all parts of the assembling rotary disc are used for assembling, meanwhile, unqualified products of insertion core sleeves can also be removed, in addition, the assembled insertion core and a rotary disc assembling part can be in seamless butt joint, and the overall machining efficiency of an optical fiber head is improved.

Owner:东莞鸿辉光联通讯技术有限公司

Manipulator having cross-in/cross-out and retardation controller

InactiveCN1903518ALow costImprove stopping accuracyProgramme-controlled manipulatorInjection molding machineManipulator

A manipulator with transverse-in and transverse-out speed-reducing controller is composed of control unit, primary arm, secondary arm, leading-pulling bean, transverse beam with transverse-out and transverse-in deceleration signal approximate switch's sensors, base and cylinder with transverse-in and transverse-out electromagnetic valves. Said sensors and electromagnetic valves are connected to said control unit.

Owner:ZHEJIANG UNIV

Clamp body for machining side plate of pulley frame, and method for machining and positioning side plate of pulley frame

ActiveCN102501101ASimple structureEasy to makePositioning apparatusMetal-working holdersRound tableEngineering

The invention discloses a clamp body for machining a side plate of a pulley frame. The upper surface of the clamp body is a working surface; two sides of a longitudinal axis of the upper surface of the clamp body is provided with symmetrical steps and a plurality of holes for positioning and installation; a short through groove are formed between two steps; the bottom of the short through groove is provided with a section of positioning surface which is provided with a step hole; the upper section of the step hole is provided with a light hole; and the lower end of the step hole is provided with a thread hole. The invention also discloses a method for machining and positioning the side plate of the pulley frame by using the clamp body; during rough machining, four round tables on the lower side of the side plate are used as positioning supporting surfaces, and multi-point positioning and pressing plate pressing modes are adopted; during finish machining, a single-point positioning mode is adopted to prevent deformation, so deformation and error are reduced; left and right pieces are machined at the same tool; and high machining accuracy and matching accuracy are achieved.

Owner:陕西天达航空标准件有限公司 +1

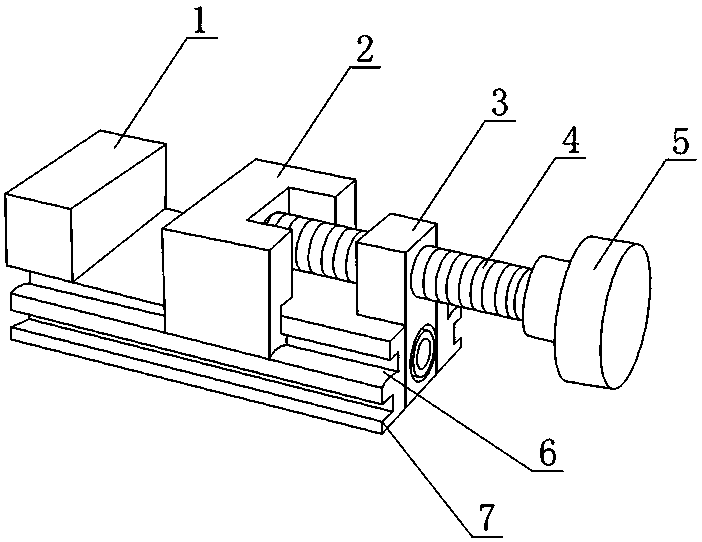

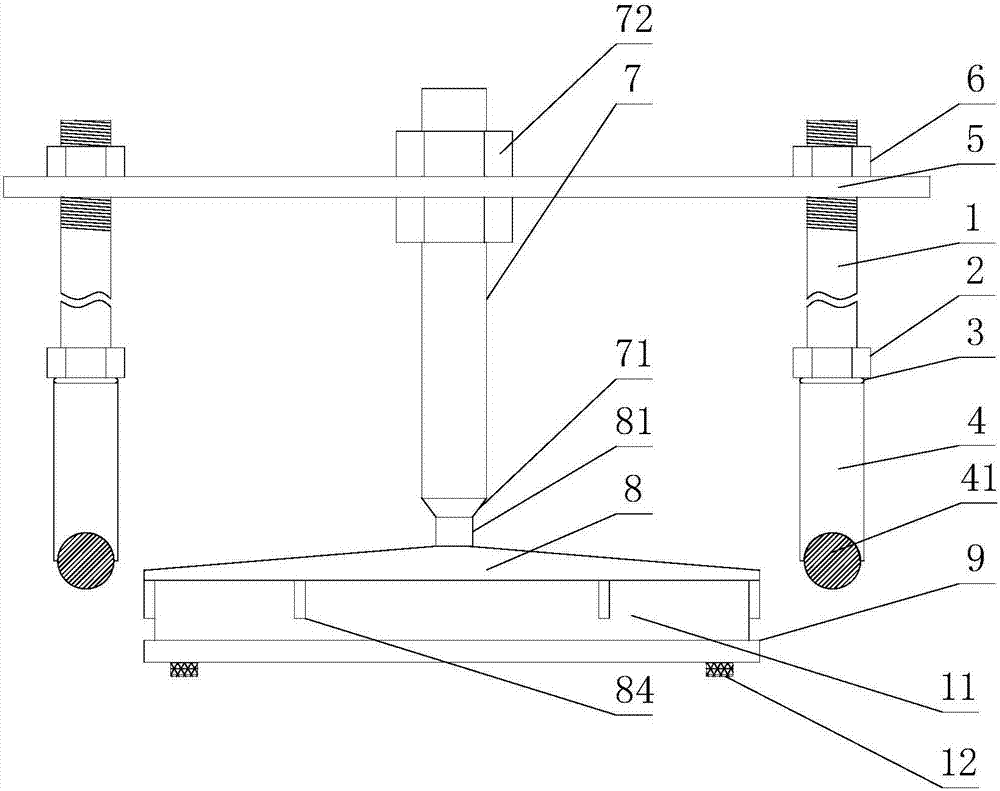

Clamping tool favorable for uniform distribution of clamping force

InactiveCN105856091AGood for uniformityConducive to fit precisionVicesMechanical engineeringDepth direction

The invention discloses a clamping tool which is beneficial to the uniformity of the clamping force distribution, comprising a base plate, a fixed block, a movable block and a pushing device for pushing the movable block to move toward the side of the fixed block, the bottom plate is strip-shaped , the fixed block is fixed on one end of the bottom plate, the pushing direction of the pushing device is along the length direction of the bottom plate, both sides of the bottom plate are provided with chute along the length direction of the bottom plate, and the movable block is provided with Two sliders that are matched with different chute respectively, the mating surface formed by the side of the chute and the bottom surface of the slider is an arc surface, and in the depth direction of the chute, the highest point of the arc surface is at Between the open end of the chute and the bottom end of the chute. When the parts are clamped, the structure is beneficial to the uniformity of force on each point on the clamping surface and to the stability of the relative positions of the fixed clamping block and the movable clamping block.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Electromagnetic nail gun

InactiveCN106625425ASimple structureLow processing and manufacturing costsNailing toolsEngineeringElectromagnet

The invention specifically relates to an electromagnetic nail gun, and belongs to the technical field of handheld tools. The electromagnetic nail gun comprises a gun body, and a nail clamping module arranged on the gun body; and the gun body includes a main body part and a handle part integrally arranged. The electromagnetic nail gun further comprises a power device arranged on the main body part; the power device includes a cylinder connected with the main body part, a collision pin slidingly sleeved on the cylinder, an electromagnet arranged on the cylinder for reciprocating driving of the collision pin, and an axial magnet arranged on the collision pin to bring convenience to the electromagnet for reciprocating driving of the collision pin; the electromagnet includes a skeleton connected with the cylinder, and a coil wound on the skeleton; and the coil is provided with a back wiring end, a front wiring end and a middle wiring end. The invention aims to slidingly arrange the collision pin on the electromagnet, directly performs reciprocating driving for the collision pin by the electromagnet, is simple in structure and reliable in operation, and meanwhile, solves the problem of higher wear of the collision pin and a slide way.

Owner:重庆福特来动力科技有限公司 +1

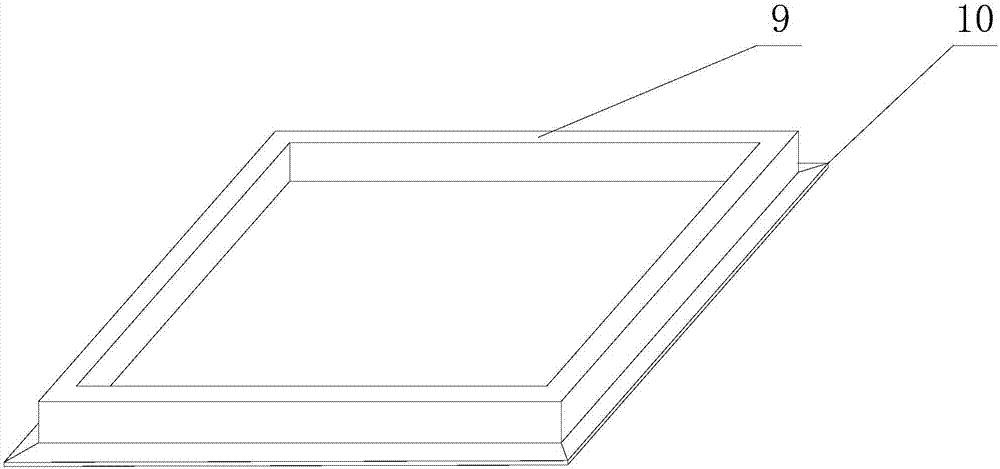

Powdery medicinal material packaging mechanism

InactiveCN106828989ASimple structureGood matching precisionFlanged caps applicationSolid materialAmpouleEngineering

The invention discloses a powder medicine packaging mechanism, which comprises a powder tank and a powder tube. The powder tube is provided with a powder tube on-off control mechanism. The side of the bottle conveying device is provided with a bottle cap installation device; the on-off control mechanism of the powder pipe includes a spring mounting seat, a discharge pipe, a first spring seat, a spring, and a discharge hole is arranged on the side wall of the discharge pipe. The lower end of the material tube is an inclined surface, and the powder material tube is threaded or bolted to the powder material tank; the ampoule transport device includes a turntable and a bottle retaining barrel, and the side of the turntable is provided with a plurality of ampoule bayonets; the bottle cap is installed The device includes a frame, a hinged rod, a fixed suction cap seat and a bottle cap feeding trough, and a suction pipe interface and a suction port are also arranged on the suction cap seat. The invention has a simple structure and is convenient to clean during use, and at the same time, its transmission form and the sealing speed of the ampoule after filling the medicinal material are beneficial to the efficacy and safety performance of the medicinal material.

Owner:陈铭鸿

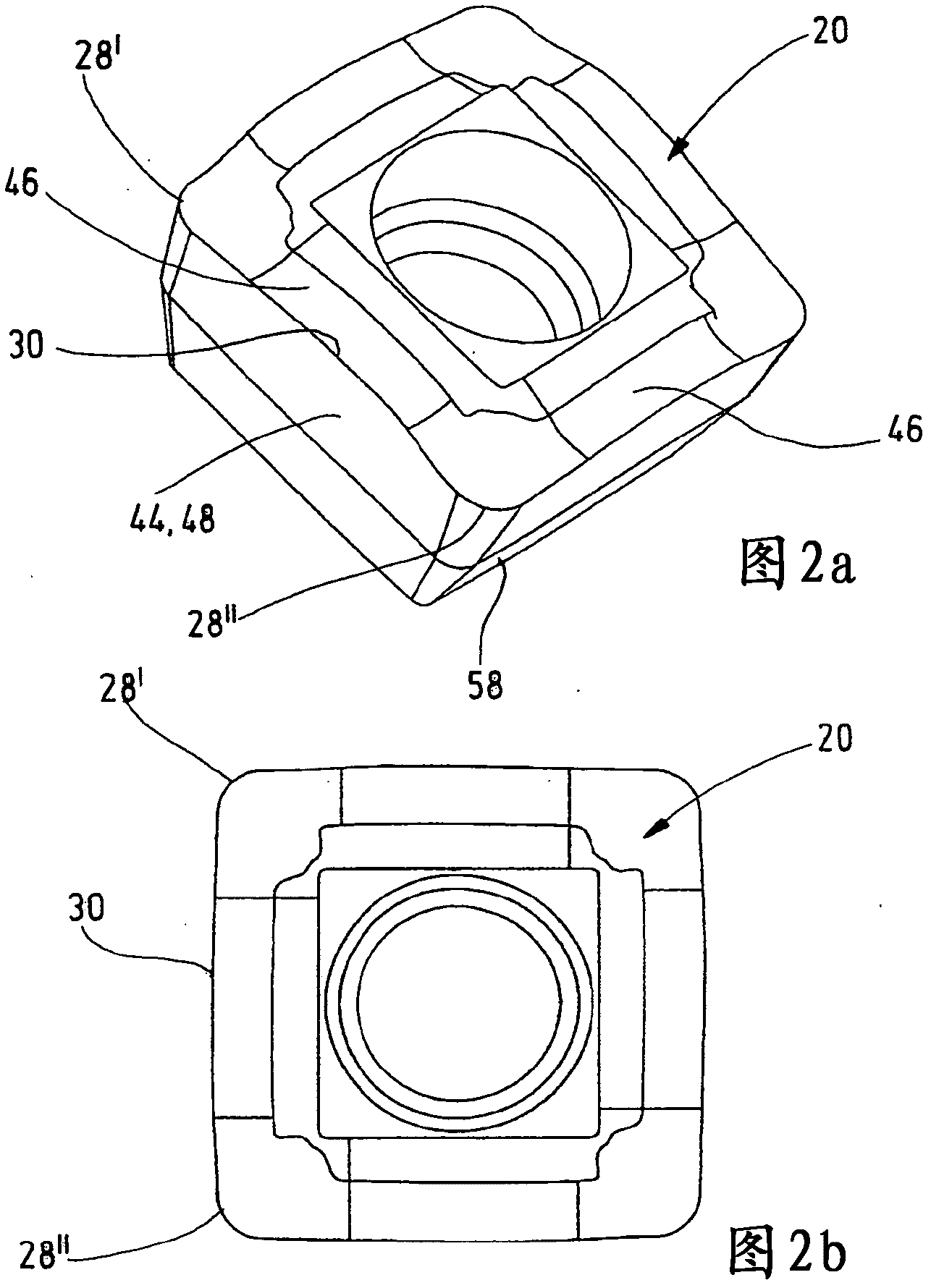

Solid drill with indexable insert

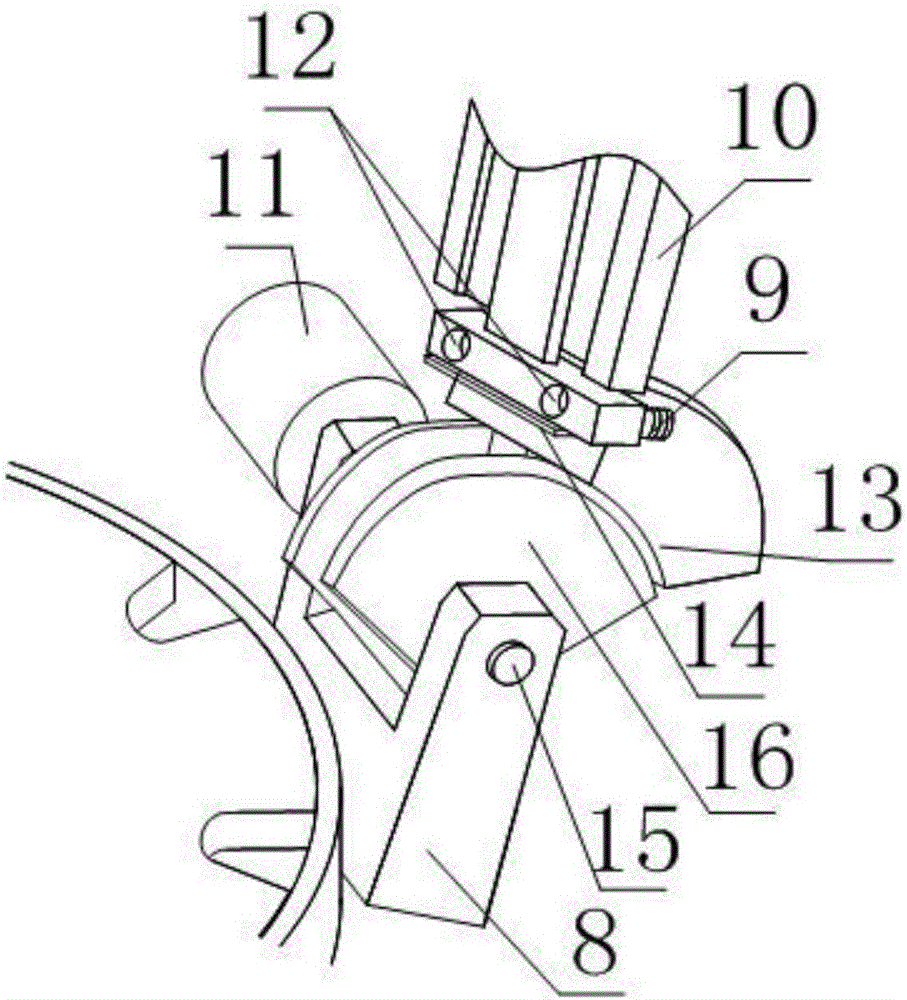

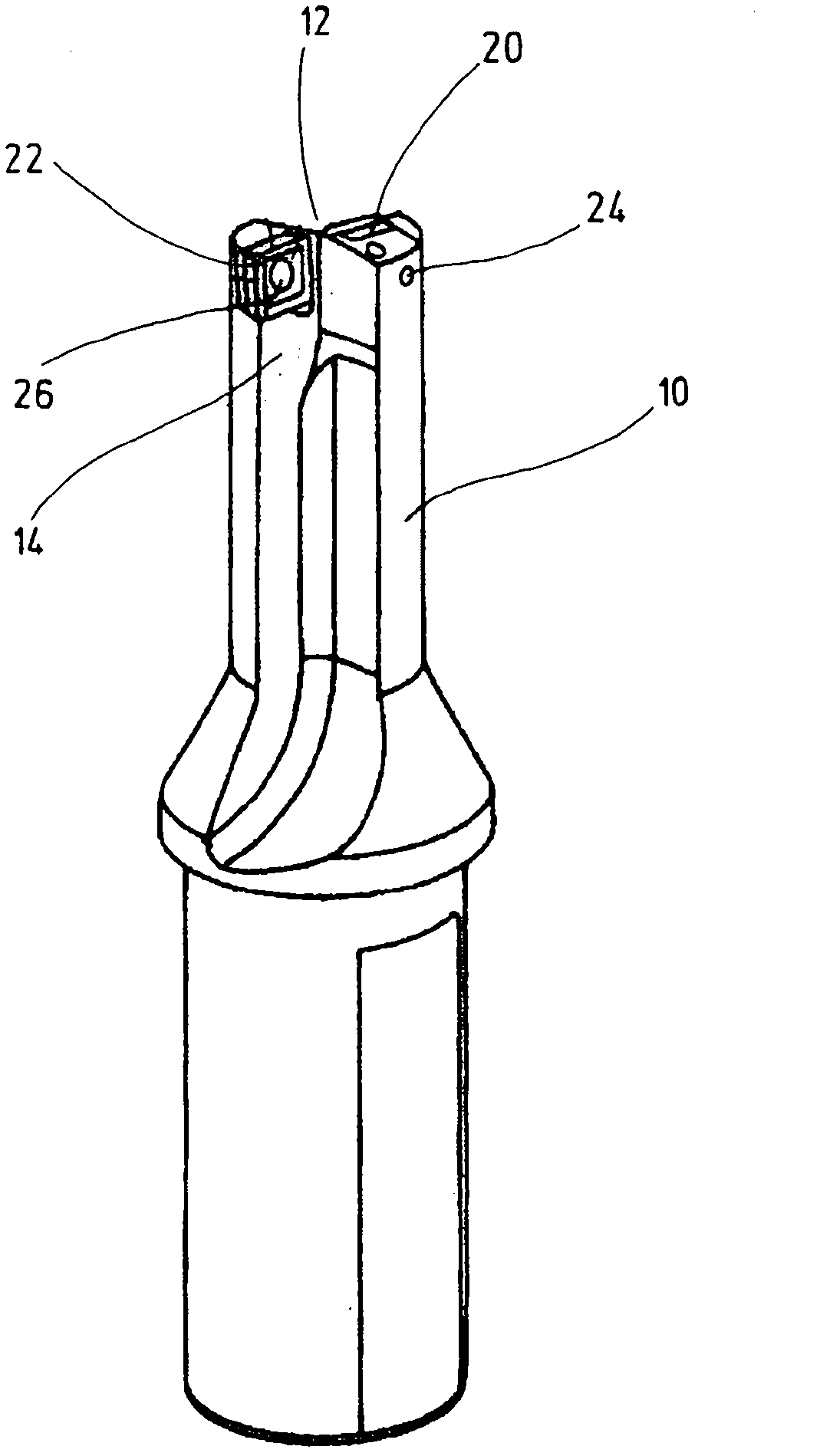

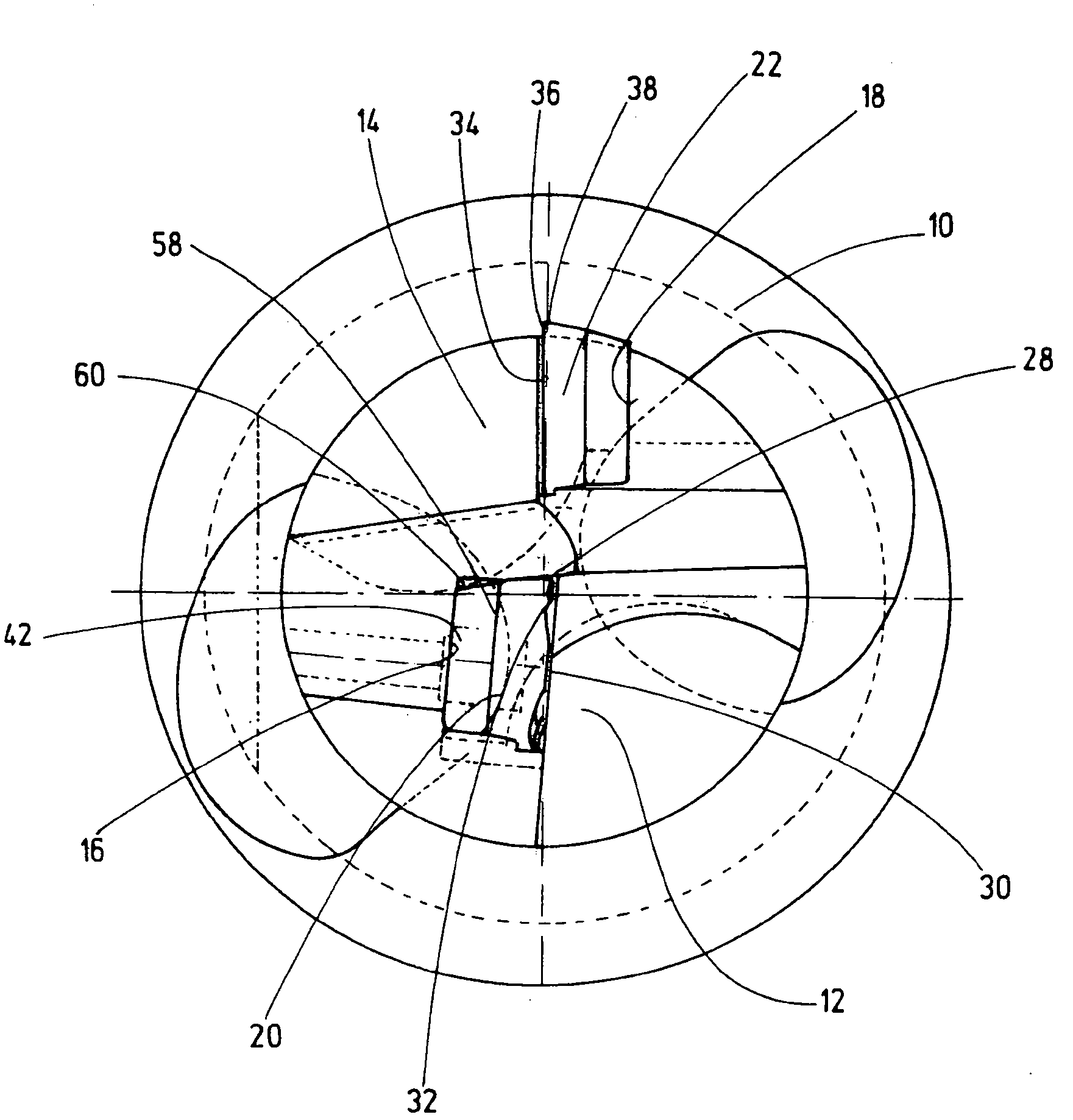

ActiveCN102319919AFavorable interconnectionHigh strengthTransportation and packagingCutting insertsWedge angleDrill bit

The invention relates to a solid drill with an indexable insert comprising four identical cutting edges (30) arranged at a distance above a supporting base (42) and each extending between two cutting-edge corners (28 ', 28 ''). The cutting edges are each bounded by a cutting face (46) and a clearance face (48), with the inclusion of a wedge angle (belta). Of the cutting edges (30), one in each case is in an active operating position during the drilling operation. To permit optimum adaptation to the cutting conditions and drilling characteristics, varying over the length of the cutting edge of the drilling tool, it is proposed according to the invention that the height (h) of the four cutting edges (30), measured from the plane of the supporting base (42), and / or the clearance angle (alpha) varies over the length of the respective cutting edges (30).

Owner:KOMET GROUP GMBH

Component fixing device

InactiveCN107756274AAvoid situations of uneven clamping forceGood clamping forceVicesSurface pointDepth direction

The invention discloses a component fixing device. The component fixing device comprises a bottom plate, a fixed clamping block, a movable clamping block and a pushing device. The bottom plate is in astrip shape, the fixed clamping block is fixed to one end of the bottom plate. Sliding grooves in the length direction of the bottom plate are formed in the two sides of the bottom plate. The movableclamping block is provided with two sliding blocks matched with the different sliding grooves correspondingly. Matched faces formed by the side faces of the sliding grooves and the bottom faces of the sliding blocks are arc faces. In the depth direction of the sliding grooves, the highest point of the position of each arc face is located between the opening end of each sliding groove and the bottom end of each sliding groove. Two sliding grooves are formed in each side of the bottom plate, and the two sliding grooves located in the same side of the bottom plate are located in the upper end and the lower end of the bottom plate correspondingly. The upper end and the lower end of the bottom plate are different in width. The connecting manner of the fixed clamping block and the pushing device and the connecting manner of the pushing device and the bottom plate are detachable connecting forms. According to the structure, when component clamping is finished, uniformity of stress of variouspoints on the clamping face is facilitated. Stability of the relative position of the fixed clamping block and the movable clamping block is facilitated, and meanwhile the service life is long.

Owner:胡峻源

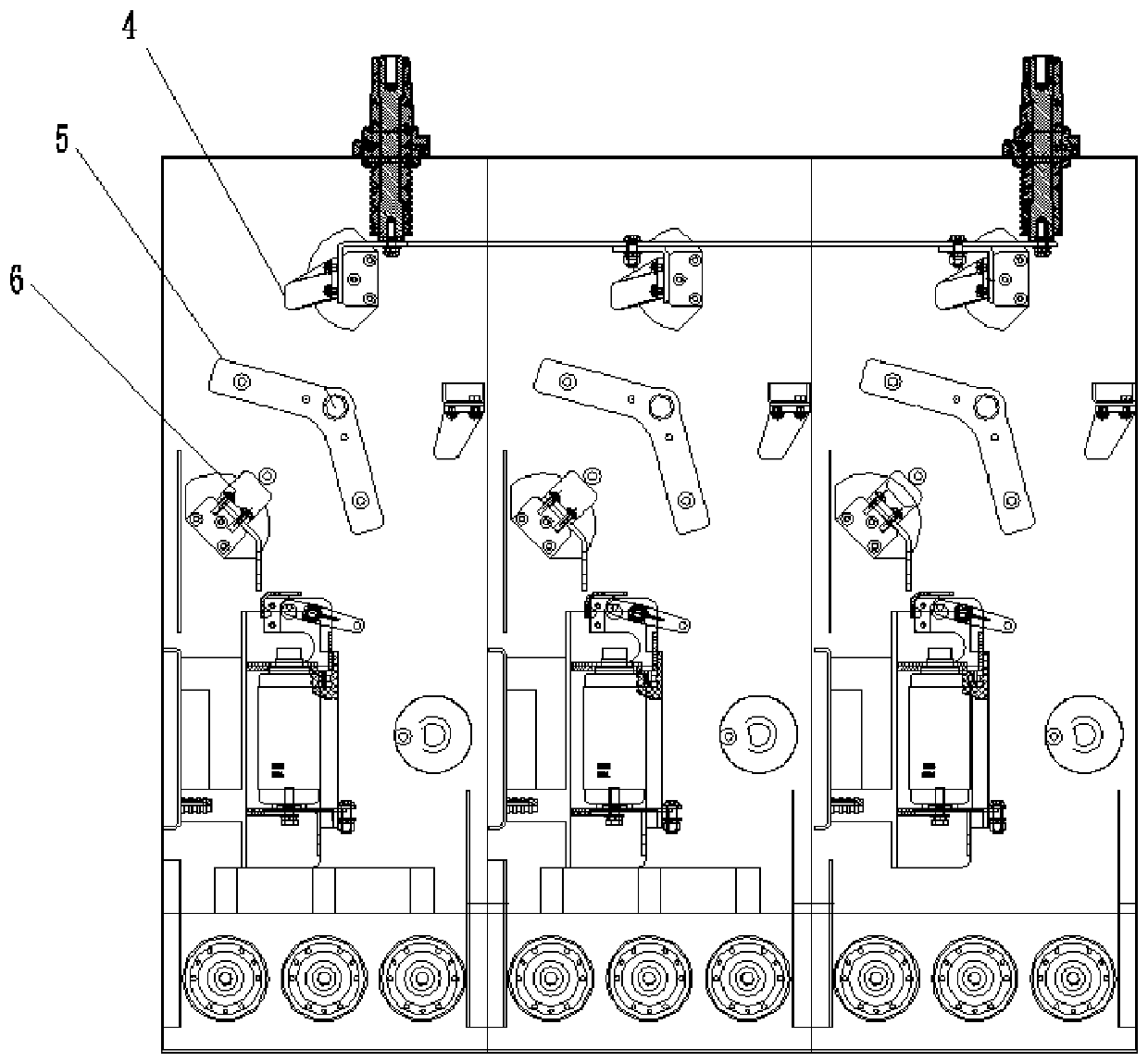

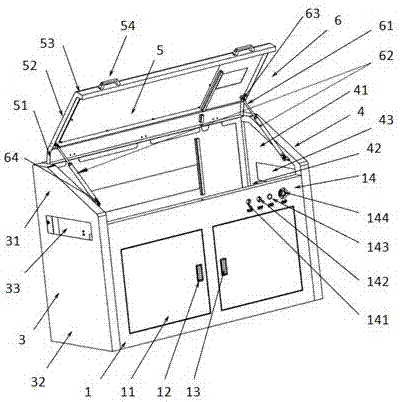

Novel environmental-protection-gas insulated totally-enclosed all-insulation ring network switch equipment

PendingCN109830911AImprove heat capacityReduce oxygen corrosionSwitchgear arrangementsCorrosionMaterials science

The invention relates to novel environmental-protection-gas insulated totally-enclosed all-insulation ring network switch equipment. The equipment comprises a stainless steel welded sealed box body and an isolation switch component installed in the stainless steel welded sealed box body. A cavity in the stainless steel welded sealed box body forms a gas box filled with an insulated gas. The upperportion of the stainless steel welded sealed box body accesses an insulation bus and a lower portion accesses a cable wiring plug. The isolation switch component is installed in the stainless steel welded sealed box body through a grounding framework, and a closing button and an opening button for controlling the isolation switch component are installed on the external portion of the stainless steel welded sealed box body. The equipment has advantages that (1) insulation performance satisfies the requirements of a power frequency withstand voltage and an impulse withstand voltage; and (2) compared with dried and purified air, the insulated gas reduces an oxygen content by half, which can improve the heat capacity of a mixed gas, and reduce the oxygen corrosion of equipment parts.

Owner:GUANGDONG AERPAL ELECTRIC POWER TECH CO LTD

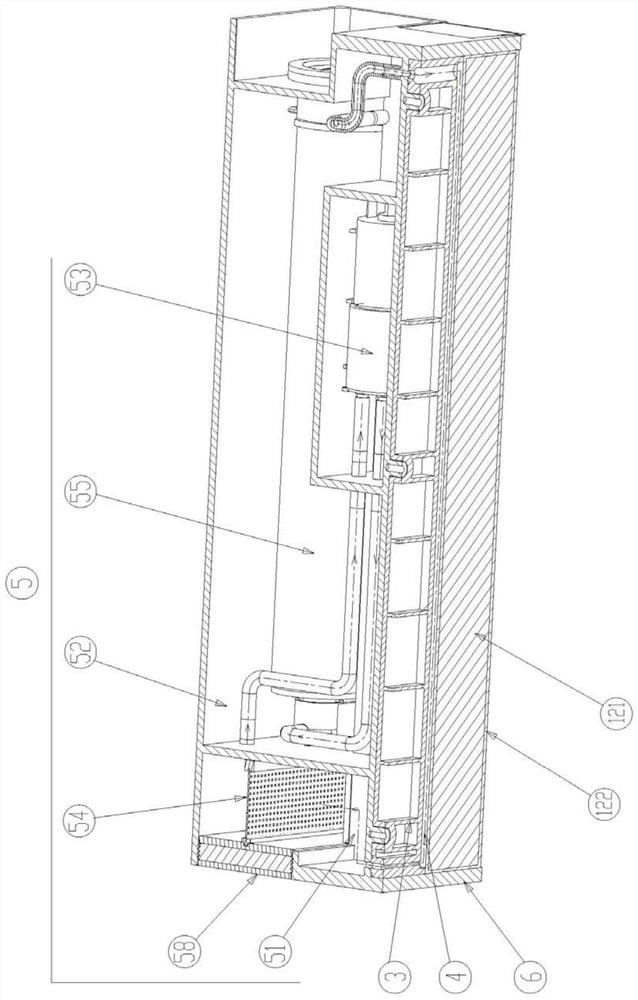

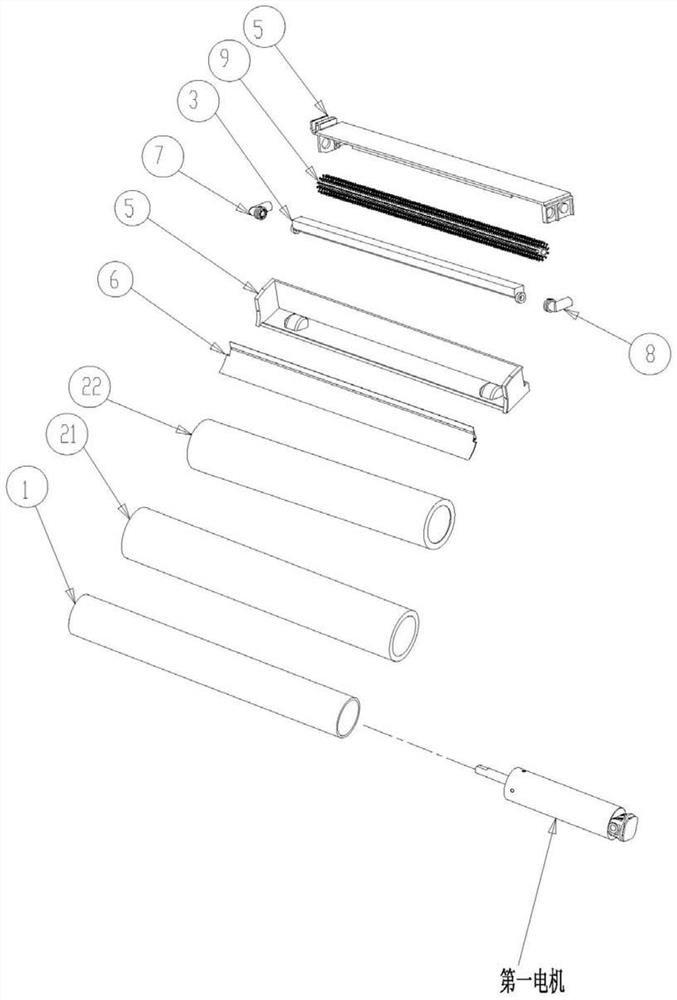

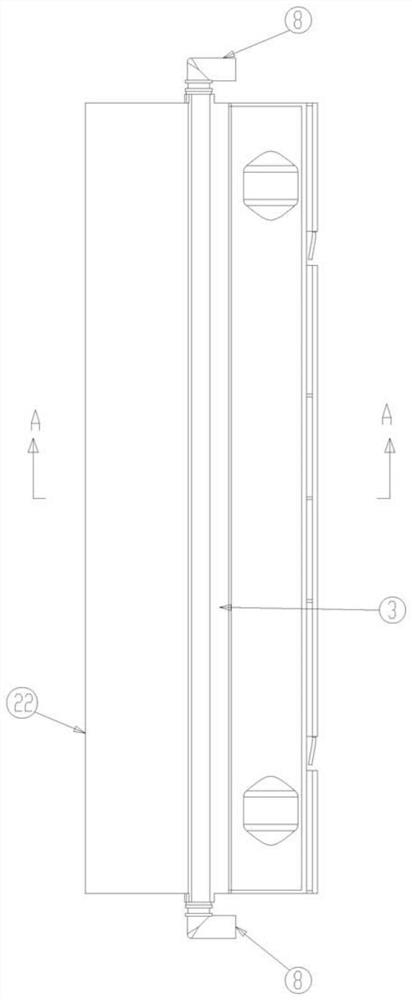

Scrubber integrated system capable of circularly filtering and recycling sewage

ActiveCN113440076AHigh circulation filtration efficiencyImprove filtering effectCarpet cleanersFloor cleanersWater flowSewage

The invention discloses a scrubber integrated system capable of circularly filtering and recycling sewage. The scrubber integrated system is characterized by comprising a shell, a roller assembly, a dust collection assembly, a water tank and a water circulation assembly are arranged in the shell, the roller assembly is arranged at the front end of the shell and used for sweeping garbage and collecting the garbage into the dust collection assembly, the water tank abuts against the roller assembly, a closed cavity for water to pass through is formed between the water tank and the roller assembly and communicated with the water circulation assembly through a liquid inlet pipeline and a liquid outlet pipeline, and the water circulation assembly can drive water to flow through the closed cavity, sewage flowing out of the liquid outlet pipeline enters the water circulation assembly to be purified and then flows into the closed cavity through the liquid inlet pipeline to achieve water circulation utilization. The system has the advantages of being exquisite in structure, capable of achieving product miniaturization, good in cleaning effect, good in use experience, low in production and manufacturing cost and beneficial to saving water, and the market application prospect is good.

Owner:GUANGDONG YUNHAN INTELLIGENT TECH CO LTD

Battery replacement system and vehicle

PendingCN111775763AImprove stabilityAvoid bumpingCharging stationsVehicular energy storageControl theoryMechanical engineering

The embodiment of the invention provides a battery replacement system and a vehicle. Rolling wheels are arranged at the bottom of a battery pack, a first sliding rail is arranged at the top of a bearing frame, a second sliding rail is arranged on a lifting mechanism, the rolling wheels of the battery pack can slide along the first sliding rail and the second sliding rail, and the driving mechanismcan drive the lifting mechanism to be switched between the lifting position and the falling position. The stability of the battery pack in the replacement process is good, the collision phenomenon can be avoided, the matching precision of the battery pack in the installation process is good, and the installation speed is high.

Owner:BEIJING JINMAO GREEN BUILDING TECH CO LTD +1

Match grinding and finish lapping technology for lining and piston in speed controller

InactiveCN109746825AGood matching precisionCooperate closelyLapping machinesGrinding feed controlMicrometerControl theory

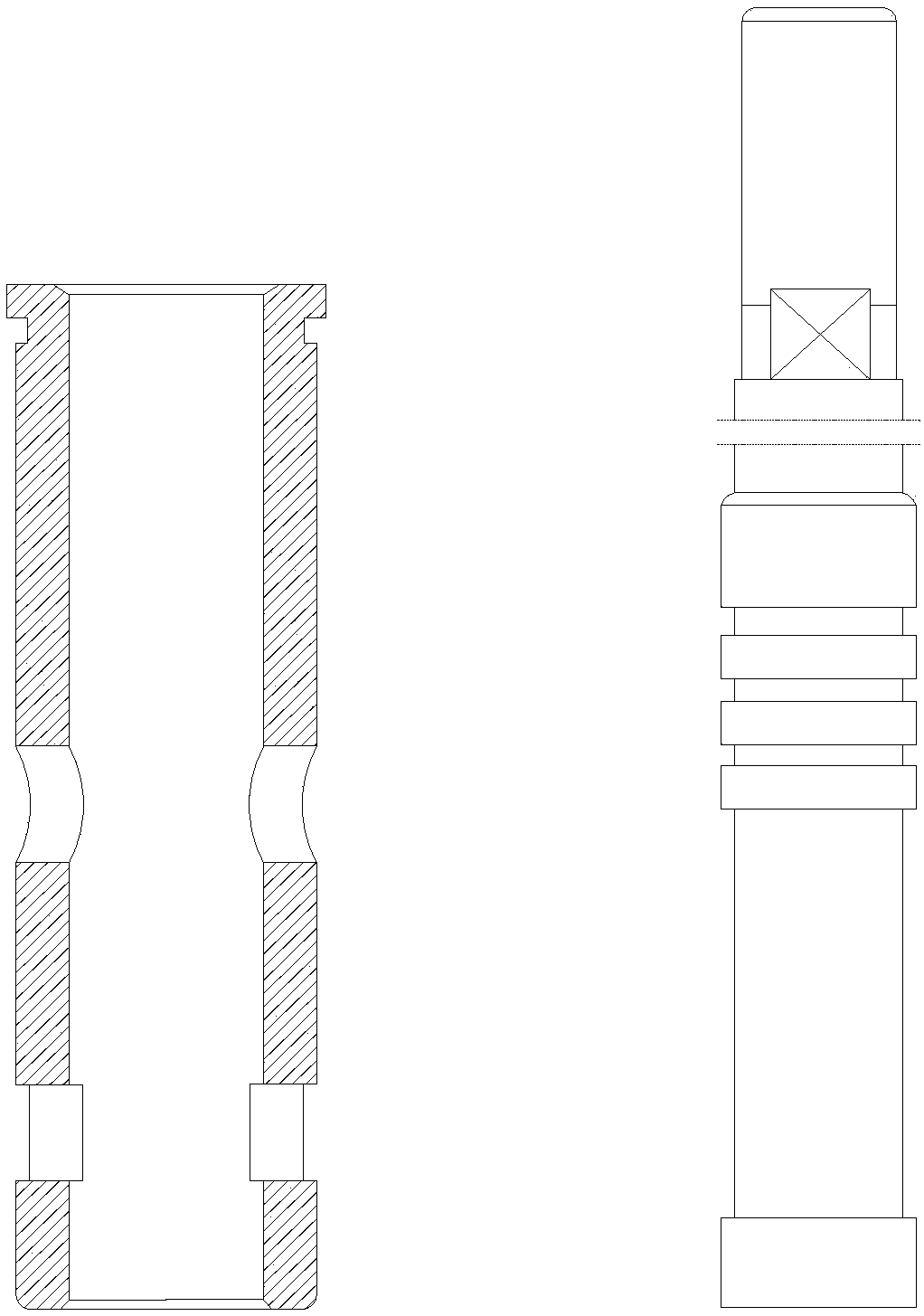

The invention provides a match grinding and finish lapping technology for a lining and a piston in a speed controller. The match grinding and finish lapping technology comprises the following steps: (1), preliminary finish lapping is conducted on a lining inner circle through an inner circle finish lapping machine, the inner circle precision of the lining is measured with a micrometer, and when the inner circle precision of the lining is measured to be an IT7 level, the preliminary finish lapping process of the lining inner circle is completed; (2), match grinding is conducted on the piston according to the practically-measured lining inner circle size, and when the match grinding lap-joint amount of the piston and the lining is detected to be smaller than 2 micrometers through a lap-jointamount testing platform, match grinding is completed; and (3), the lining and the piston are both installed on a workbench of the same inner circle finish lapping machine, and mutual finish lapping is conducted on an outer circle of the piston and the inner circle of the lining according to the following finish lapping technology parameters: speed of the piston is between 2 m / s and 4 m / s, and thespeed of the lining is between 0.5 m / s and 0.6 m / s. According to the match grinding and finish lapping technology for the lining and the piston in the speed controller, the high matching precision between the lining and the piston is achieved; the piston is matched with the lining more tightly and more reliably; and therefore, the oil leakage amount of the speed controller is decreased, and the service life of the speed controller is prolonged.

Owner:TIANJIN YUANYUAN SYNTHETIC TECH DEV CO LTD

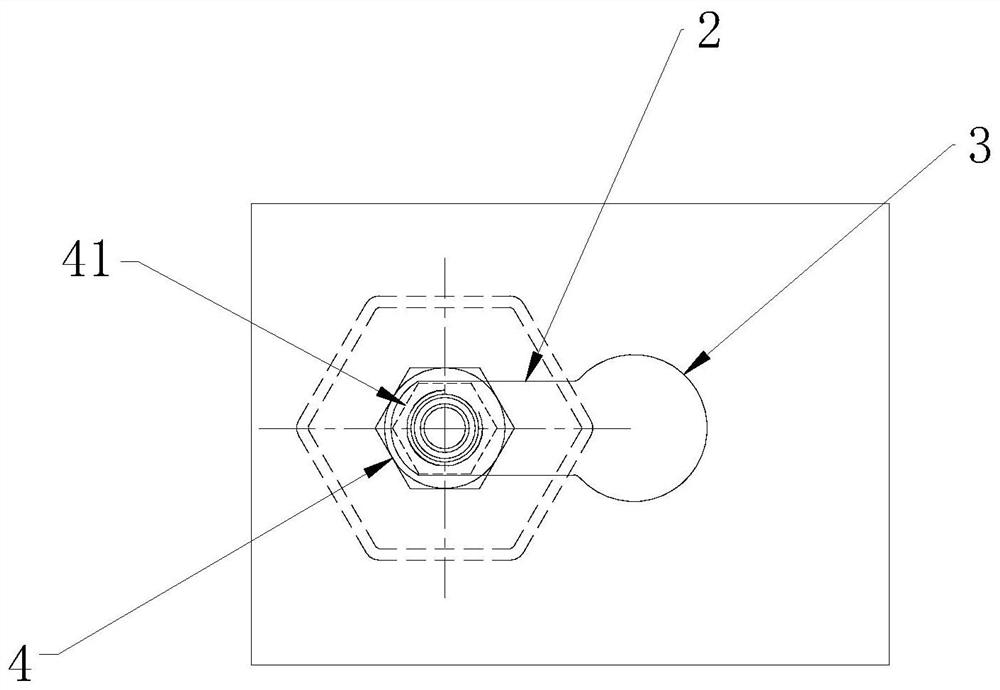

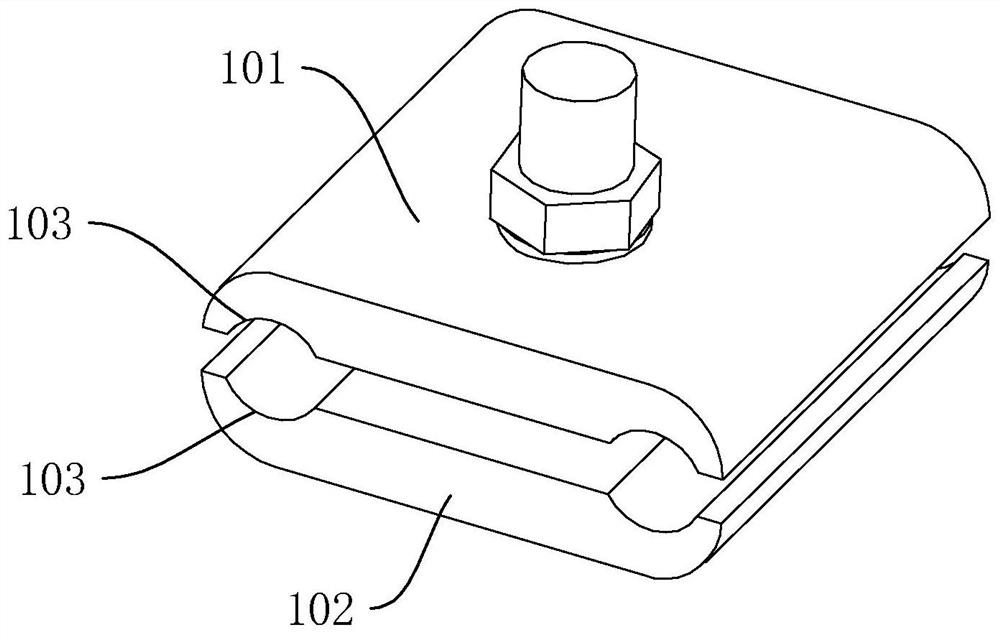

Adjustable foot and washing machine

ActiveCN111850995AEasy to limitPlay a limiting roleOther washing machinesTextiles and paperLaundry washing machineEngineering

The invention discloses an adjustable foot. The foot comprises a supporting base, a bolt, an adjusting nut, and a locking nut. One end of the bolt is fixedly connected with the supporting base. The adjusting nut is connected with the other end of the bolt in a threaded mode. The locking nut is arranged on the bolt between the adjusting nut and the supporting base. A positioning structure is arranged on the adjusting nut, and is used for assembly. The positioning structure is positioning clamping slots formed in at least one of the outer wall surfaces of the adjusting nut. The adjusting nut isa hexagon nut. The positioning structure is positioning clamping slots formed in two outer wall surfaces, opposite to each other, of the hexagon nut, or positioning clamping slots formed in the wholeperipheral wall of the periphery of the hexagon nut. The invention also discloses a washing machine with the adjustable foot. A bottom plate of the washing machine is provided with clamping holes, andthe positioning clamping slots of the adjusting nut are clamped inside the clamping holes. Therefore, the assembly of the adjustable foot and the washing machine is realized with high assembly efficiency.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Mechanical password device

The invention discloses a mechanical password device. The mechanical password device comprises a base, a spring bolt plate and a spring bolt spring, wherein the spring bolt plate is mounted on the base in a sliding manner; the two ends of the spring bolt spring are respectively propped against the spring bolt plate and the base; the mechanical password device further comprises a limiting plate, a rotating disc, a password wheel and a clutch spring; the rotating disc is mounted on the base; the password wheel is matched with the rotating disc; the limiting plate is arranged on the base; the clutch spring is arranged in the base; the two ends of the clutch spring are respectively propped against the limiting plate and the base; an inner concave part is formed in the password wheel; and a bulge matched with the inner concave part is arranged on the limiting plate. The mechanical password device has the benefits that the password wheel is not in friction contact with the limiting plate during the rotating process, so that the password wheel is not abraded with the limiting plate during the rotating process, and the good matching precision between the password wheel and the limiting plate is ensured.

Owner:浙江德施曼科技智能股份有限公司

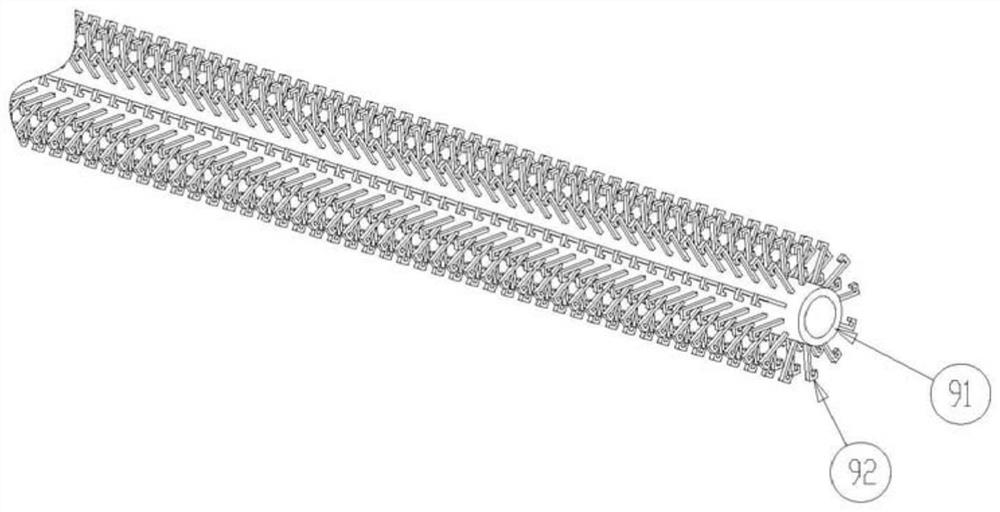

Roller assembly for cleaning and cleaner applying roller assembly

PendingCN113440077AImprove wear resistanceAvoid disadvantagesCarpet cleanersFloor cleanersSurface cleaningStructural engineering

The invention discloses a roller assembly for cleaning and a cleaner applying the roller assembly, the roller assembly for cleaning comprises a roller shaft and an elastic roller wrapping the roller shaft, the roller shaft can rotate under the action of a driving unit to drive the elastic roller to rotate for surface cleaning, the elastic roller comprises an inner roller body and an outer roller body, the inner roller and the outer roller are both made of elastic non-absorbent materials, and the hardness of the elastic material of the inner roller is smaller than that of the material of the outer roller. The cleaner is reasonable in structure, convenient to use, good in cleaning effect, good in use experience, beneficial to meeting the use requirements of sanitation and health and wide in market prospect.

Owner:GUANGDONG YUNHAN INTELLIGENT TECH CO LTD

High-performance spring air hole sleeve

A high-performance spring air hole sleeve comprises a valve shell, a mandrel and a spring, a frustum portion and a spigot portion are arranged at the two ends of the mandrel, one end of a hole cavity of the valve shell is a taper hole matched with the frustum portion of the mandrel in a sealing mode, the other end of the hole cavity of the valve shell is a gear portion limiting the spigot portion of the mandrel outside the valve shell, the spring sleeves the mandrel, and the two ends of the spring abut against the frustum portion and the gear portion respectively; a notch groove is formed in the top end of the spigot portion of the mandrel or the top end of the gear portion of the valve shell to form a multi-clack structure; the whole valve shell is in a cylindrical step shape, the end of an outer cylinder of the gear portion is a conical surface, and a plurality of circumferential grooves arranged in parallel are formed in the surface of the outer cylinder at a conical hole; a transition shaft section with the diameter larger than that of a shaft body is arranged at the joint of the frustum portion and the shaft body of the mandrel, an arc-shaped ring groove is formed in the connecting point of the transition shaft section and the frustum portion, and the end face of the frustum portion of the mandrel is arranged to be in a mushroom head shape. According to the high-performance spring air hole sleeve, the matching precision with a mold exhaust port is high, the stability is good, the exhaust effect is good, the vulcanized product is beautiful and flat, and the product quality is good.

Owner:吴文朝

Loading and unloading disc belt transmission device for loading and unloading machine

The invention relates to a loading and unloading disc belt transmission device for a loading and unloading machine. The loading and unloading disc belt transmission device is characterized by comprising a motor, a T-shaped plate, wing plates, supporting plates, a motor belt component, a motor fixing plate component, conveyer belt components and a switch component. Aiming at the deficiencies and the defects in the prior art, the loading and unloading disc belt transmission device for the loading and unloading machine is adopted and is rapid in conveying speed, high in efficiency, good in matching accuracy and high in automation degree; a conveyer belt is fixed at the bottom end and the top end, and two groups of the conveyer belt components are symmetrically arranged, so that the stability of the conveyer belt components during working is improved; the internal structure is simplified, and materials and cost are saved; and the center of gravity of the belt transmission device is balanced onto the axisymmetric center of the T-shaped plate, so that the running stability of the belt transmission device is improved, and the service life of the belt transmission device is prolonged.

Owner:江苏富联通讯技术有限公司

Rotating shaft structure of circuit breaker release

ActiveCN102446665AQuick installationPrevent tamperingProtective switch operating/release mechanismsPhysicsEngineering

The invention relates to a rotating shaft structure of a circuit breaker release and belongs to the field of low-voltage electrical techniques. The rotating shaft structure of the circuit breaker release comprises a support and a rotating shaft body. A first rotating shaft installation hole is arranged on a support wall on one side of the support. The rotating shaft body is arranged in the first rotating shaft installation hole. The rotating shaft structure of the circuit breaker release is characterized in that a first open groove is formed on one side of the first rotating shaft installation hole towards the rotating shaft body, the width of the first open groove is smaller than the diameter of the first rotating shaft installation hole and is larger than the diameter of the matching section of the rotating shaft body, wherein the matching section is used for being matched with the first rotating shaft installation hole, a first shaft sleeve is sheathed on the rotating shaft body, the first shaft sleeve is provided with a first working section and a first step, the first working section is installed in the first rotating shaft installation hole and is matched with the first rotating shaft installation hole, the outer diameter of the working section is larger than the width of the first open groove on the support, and the diameter of the first step is larger than the diameter of the first rotating shaft installation hole. The rotating shaft structure of the circuit breaker release has the advantages that the assembling efficiency is improved, the rotating shaft body is prevented from running out, the rotating effect of the rotating shaft body is reflected to the utmost extent and finally the working reliability of a circuit breaker is guaranteed.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

Conveying line metal plate cover

The invention relates to a conveying line metal plate cover. The conveying line metal plate cover is characterized in that the metal plate cover comprises fifth faces including a front face, a rear face, a left side face, a right side face and an upper cover. The conveying line metal plate cover overcomes the defects in the prior art, the feeding and discharging conveying speed is high, efficiency is high, the cooperation precision is good, and the automation degree is high; a metal plate technology is adopted in shells of all the faces of the metal plate cover, stability is good, safety is good, and the service life is long; the internal structure is simplified, materials are saved, and cost is saved; and an instrument panel and an observation window are arranged, working personnel can know the internal working state outside in real time, adjustment can be conducted conveniently in time, and the overall testing efficiency is improved.

Owner:江苏富联通讯技术股份有限公司

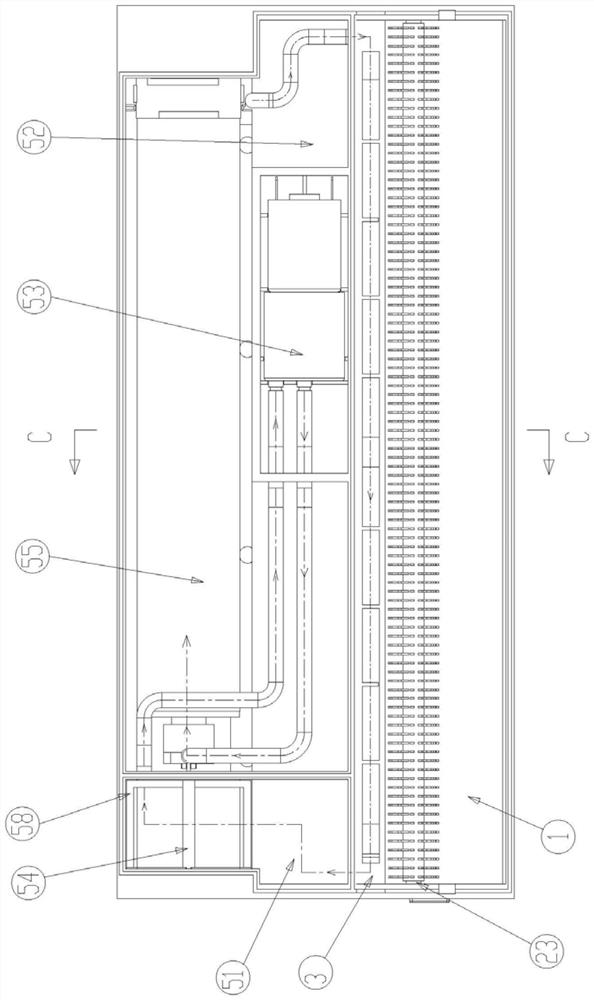

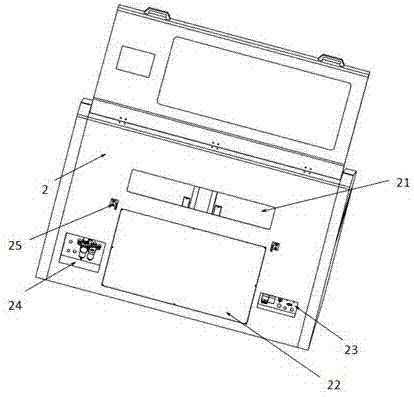

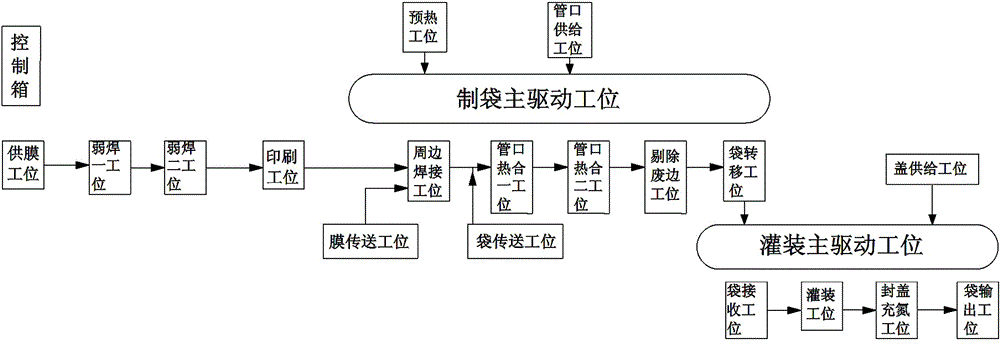

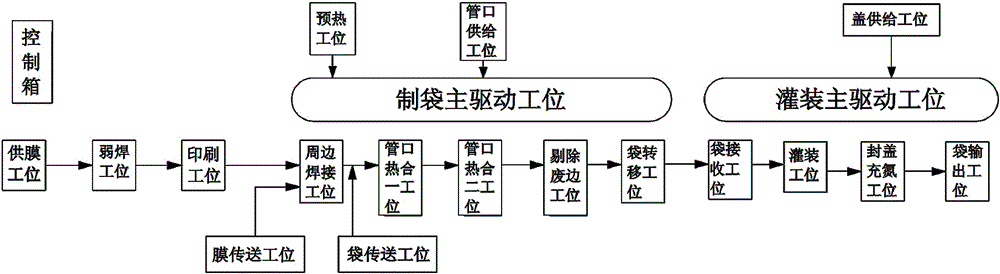

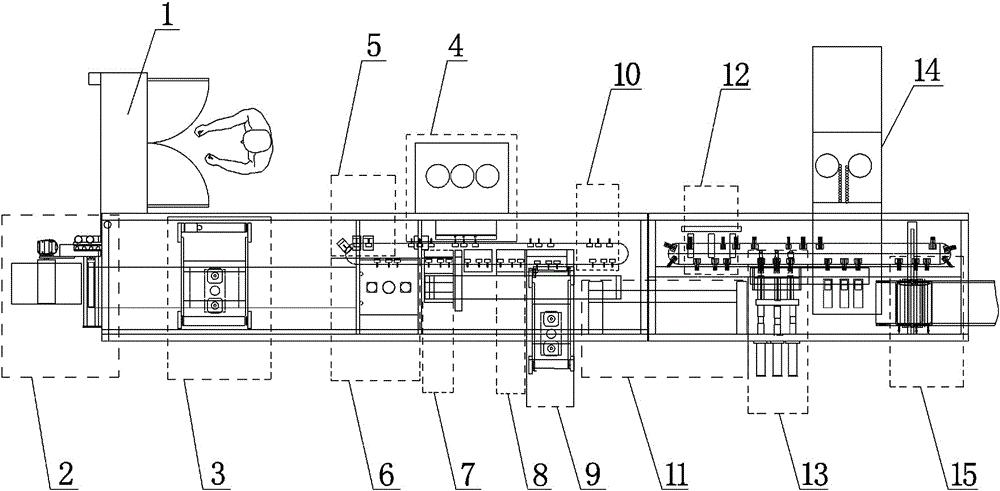

A fully automatic liquid-liquid multi-chamber bag making and filling machine

The invention discloses a full-automatic liquid-liquid multi-chamber bag manufacturing, filling and sealing machine comprising a control part (1) and an execution part. The execution part comprises a bag manufacturing part and a filling part, the bag manufacturing part comprises a film supply station (2), a bag body printing station (3), a pipe opening supply station (4), a pipe opening pre-welding station (5), a bag body outline welding station (6), a pipe opening welding station (7), a bag body shaping and scrap edge removing station (8), a weak welding station (9), a first bag body transfer station (10) and a second bag body transfer station (11), and the filling part comprises a bag body receiving station (12), a filling station (13), a plugging and nitrogen inflating station (14) and a bag body output station (15). The full-automatic liquid-liquid multi-chamber bag manufacturing, filling and sealing machine has the advantages that layout is reasonable, efficiency is high, operation is stable, cost is low, the probability that liquid leaks from the welded portion of a bag body infusion accessory and a bag body can be reduced in the bag manufacturing process, and the machine can meet the production requirement of liquid-liquid multi-chamber bags of different specifications and varieties.

Owner:SICHUAN KELUN PHARMA CO LTD

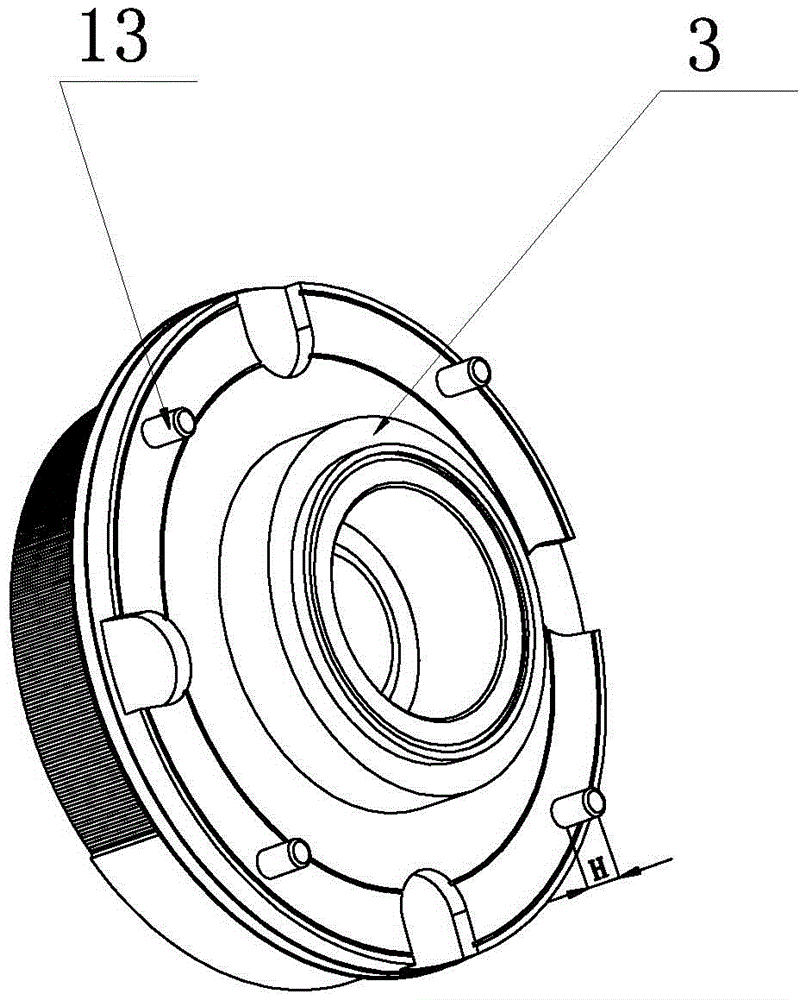

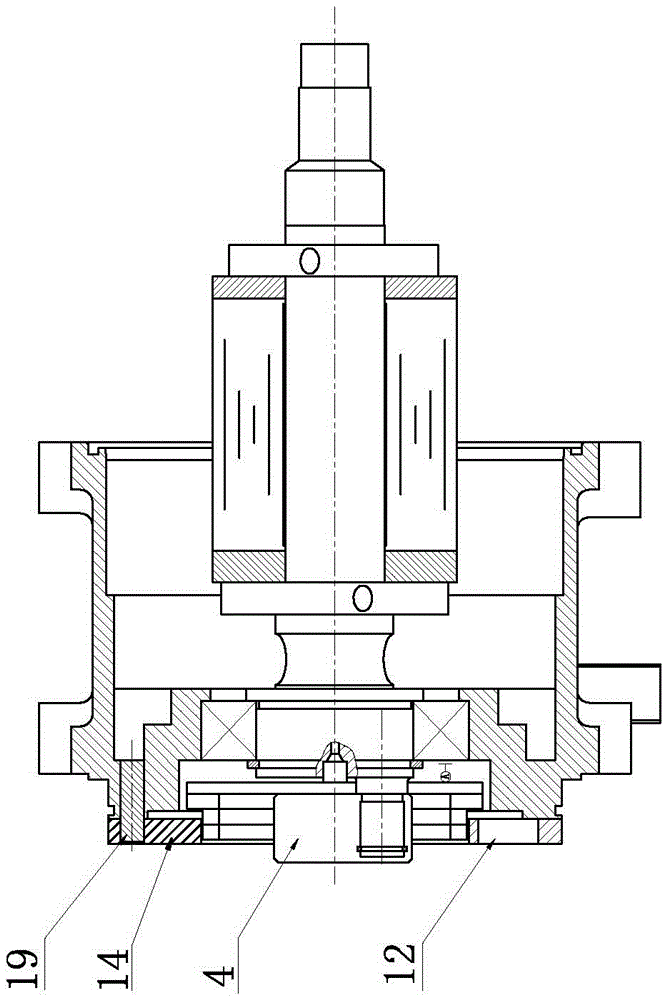

Scroll compressor with ring pin structure

ActiveCN103727031BImprove performanceImprove convenienceRotary piston pumpsRotary piston liquid enginesEngineeringCrankshaft

The invention discloses a vortex compressor with a gasket pin structure. The vortex compressor with the gasket pin structure comprises a machine shell (1), a static disk (2), a dynamic disk (3), an eccentric sleeve (4), a crankshaft (5) and a front cover (6), and is characterized in that pins (13) are arranged on the end surface, opposite to the front cover (6), of the dynamic disk (3); a gasket (14) with the thickness of 3 to 5.5 mm, the hardness of HRC 40 to 50, the material of 40Cr or 20CrMo is arranged on the end surface, opposite to the dynamic disk (3), of the front cover (6); circular holes (12) with the same number as that of the pins (13) are formed in the gasket (14); the height H of each pin (13) is equal to 80 to 95 percent of the thickness of the gasket (14); the gasket (14) is positioned on the end surface, opposite to the dynamic disk (3), of the front cover (6) through a positioning pin (19); the positioning pin (19) is in clearance fit with the corresponding positioning hole (14a) in the gasket (14); the fit clearance between the positioning pin (19) and the positioning hole (14a) is 0.045 to 0.127. The vortex compressor with the gasket pin structure has the advantages of simple structure, light weight and convenience in installation.

Owner:NANJING AOTECAR NEW ENERGY TECH

Interface element, interface element holder and electrical appliance

ActiveCN101932410BPrecise positioningImprove anti-pollution performancePortable power-driven toolsConnectionsMechanical engineeringElectronic equipment

Owner:ROBERT BOSCH GMBH

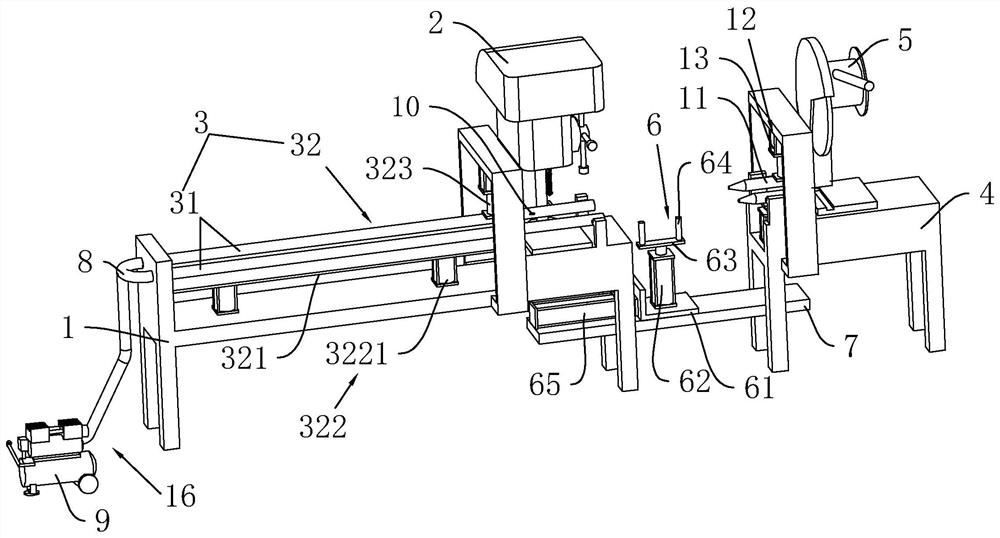

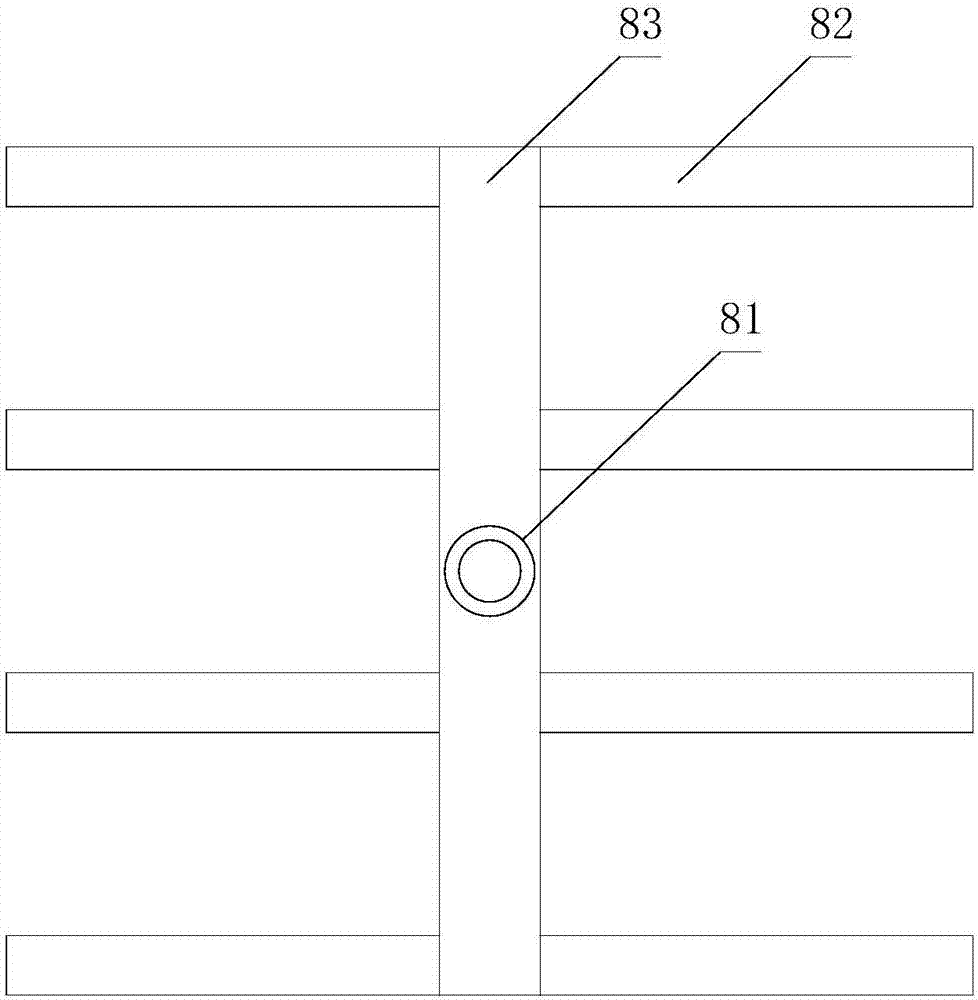

Parallel groove clamp processing device with high matching degree

ActiveCN111613951AGood matching precisionExtended service lifeOther manufacturing equipments/toolsClip conductor connectionEngineeringWorkbench

The invention relates to a parallel groove clamp machining device with high matching degree. The device comprises a workbench and a perforating machine arranged on the workbench, a cutting table is arranged at one side of the workbench, and a cutting machine is arranged on the cutting table. A pushing assembly is arranged between the workbench and the cutting table, the workbench is provided witha positioning mechanism used for positioning an upper strip material and a lower strip material, and the positioning mechanism comprises a positioning rod which is horizontally arranged above the workbench. The positioning mechanism further comprises a clamping assembly used for clamping the upper strip material and the lower strip material to the upper side and the lower side of the positioning rod, the clamping assembly comprises a long plate arranged below the positioning rod and used for supporting the lower strip material, a driving piece used for driving the long plate to ascend and descend is arranged on the workbench, the clamping assembly further comprises a first air cylinder arranged above the positioning rod, and a cooling assembly used for cooling a drill bit of the perforating machine is arranged on the positioning rod. The parallel groove clamp machining device has a high-precision perforating effect.

Owner:宁波奉欣电力金具实业股份有限公司

Honeycomb core component

The invention discloses a honeycomb core component, which comprises a honeycomb core main body, a sealing piece for sealing the bottom face of the honeycomb core main body with the top face of a template, and an anti-floating structure for providing anti-floating restriction for the honeycomb core main body. The honeycomb core component further comprises a fence edge, and the fence edge is used for fixing on the template; after the honeycomb core main body is placed at the installing position of the template, every side of four sides of the honeycomb core main body contacts with the inside of the fence edge. In the honeycomb core component, the sealing piece can reliably display the sealing effect.

Owner:CHINA MCC5 GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com