Powdery medicinal material packaging mechanism

A technology for medicinal materials and packaging, which is applied in the field of production equipment of ampoule filling lines of pharmaceutical companies, can solve the problems of high mechanical failure rate, affecting the efficacy and safety performance of medicinal materials, and inconvenient cleaning of equipment, and achieves long practical life and structure. Simple, time-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

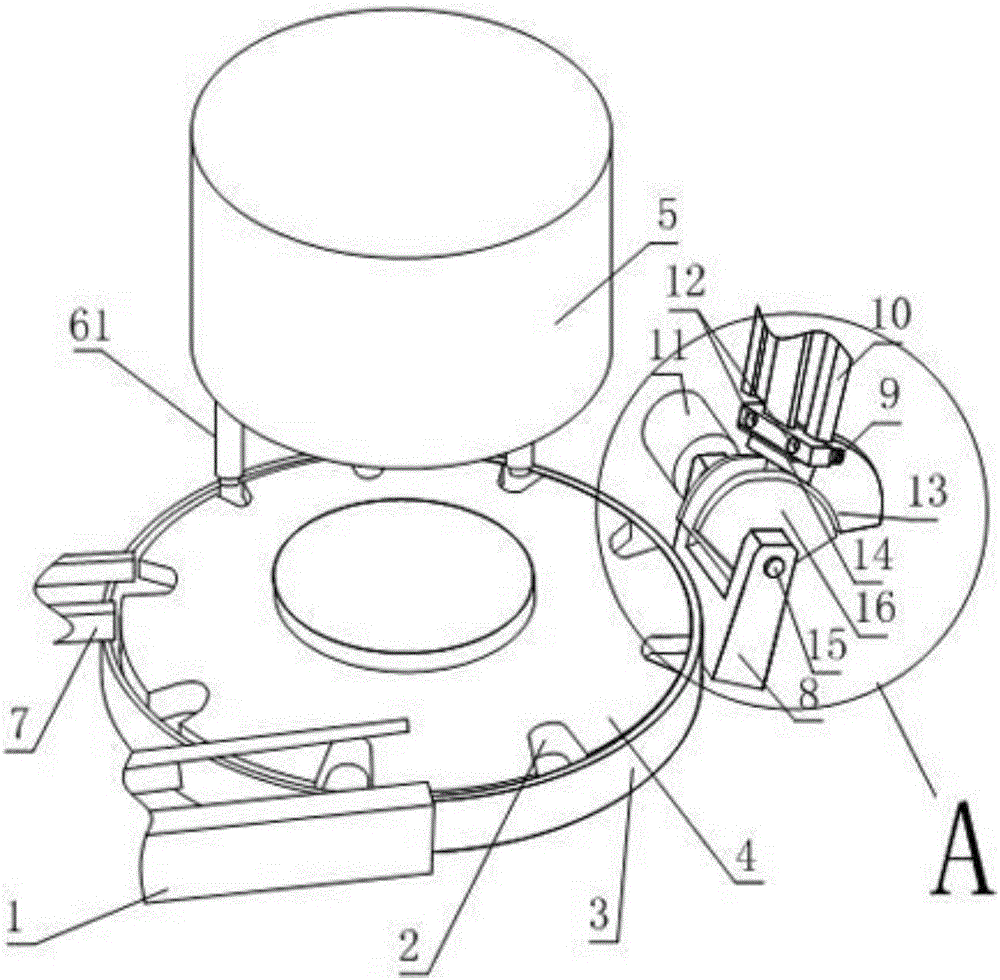

[0023] Embodiment 2: This embodiment is further limited on the basis of Embodiment 1: as figure 1 with figure 2 , for the convenience of conveying the ampoule on the turntable 4 and unloading the ampoule from the turntable 4, it also includes a bottle outlet groove 1 and a bottle inlet groove 7, the bottle retaining barrel 3 is provided with two gaps, and the bottle outlet groove The outlet end of 1 and the inlet end of bottle-feeding tank 7 are respectively located in a breach.

[0024] In order for the ampoule to be securely confined in the ampoule bayonet 2, the gap between the side wall of the turntable 4 and the bottle retaining barrel 3 is not greater than 1mm, and the width of the ampoule bayonet 2 gradually increases from its opening end to the end. decrease.

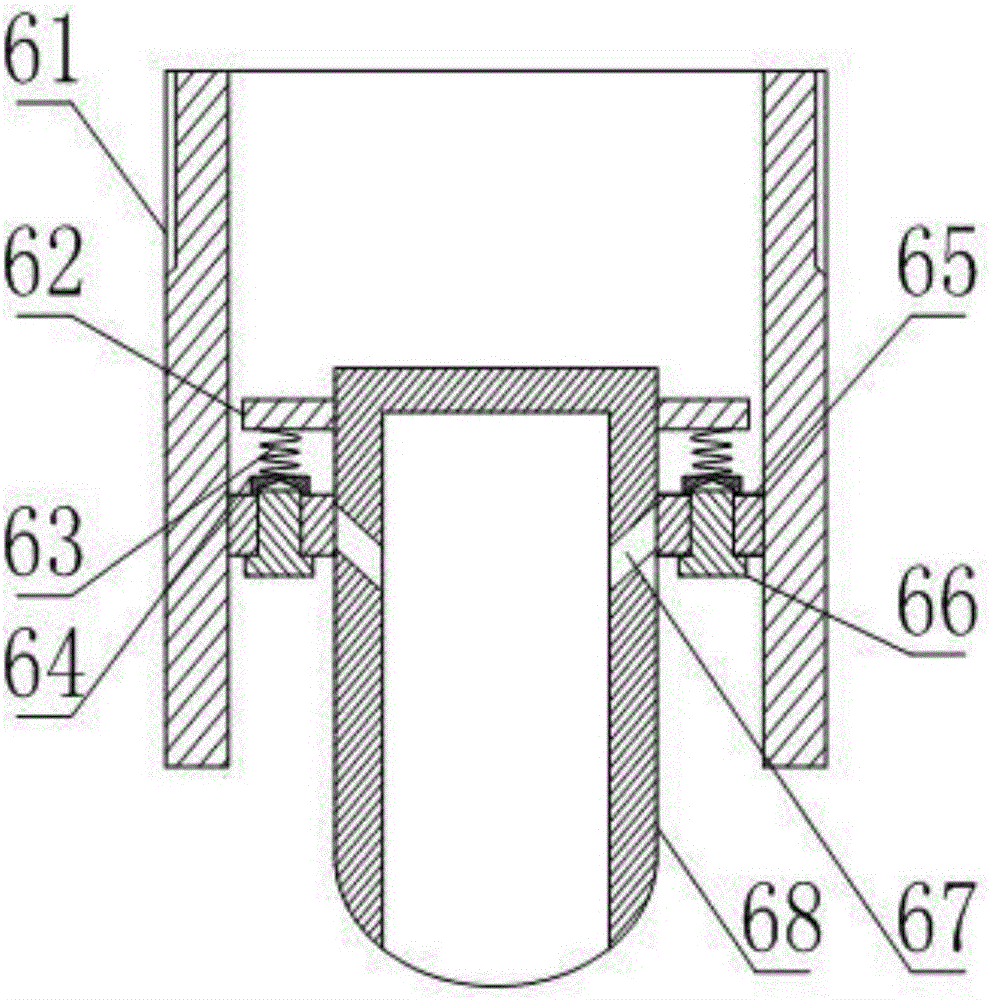

[0025] For the convenience of cleaning of the present invention, a second spring seat 64 is also included, and the two ends of the spring 63 are fixedly connected with the first spring seat 62 and the second ...

Embodiment 3

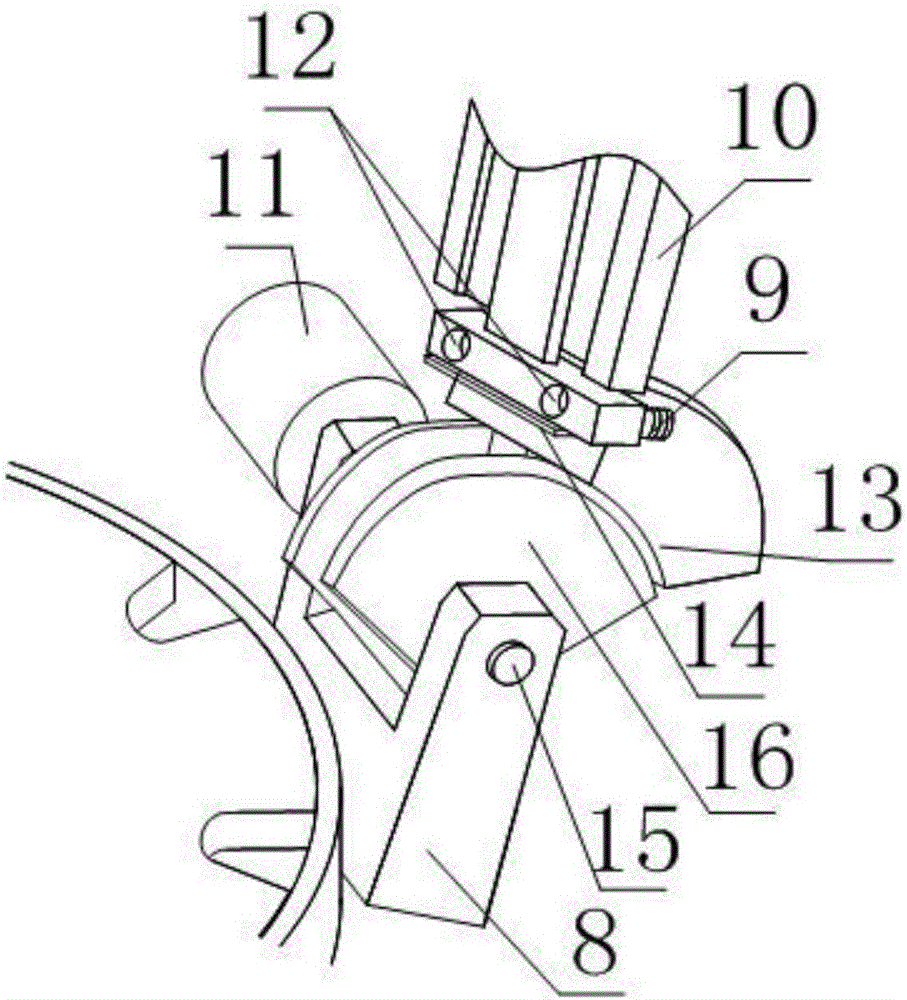

[0026] Embodiment 3: This embodiment is further limited on the basis of Embodiment 1: as figure 1 with figure 2 , in order to facilitate the drug material falling from the discharge pipe to enter the ampoule more concentratedly, and the drug material can easily leak from the discharge hole, the discharge pipe 68 is a circular tube, and the discharge hole 67 There are more than one, and they are evenly distributed in a ring shape around the discharge pipe 68; the discharge hole 67 is an oblique hole inclined towards the center of the discharge pipe 68; in order to prevent the bottle cap from falling to the suction port 12 Slipping off from the present invention, the bottle cap installation device also includes a material stopper 14, the material stopper 14 is fixed on the suction cap seat 13 and is located below the suction port 12, and the set material stopper 14 is also conducive to The positioning accuracy of the bottle cap and the suction port 12. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com