Honeycomb core component

A technology of honeycomb core and components, which is applied in the direction of building components, floors, buildings, etc., and can solve the problem that the honeycomb core and formwork seal cannot achieve the sealing effect, the positive pressure of the honeycomb core formwork is small, and the tension force of the honeycomb core wire rope is different. problems, to achieve good fit precision, reliable sealing effect, and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

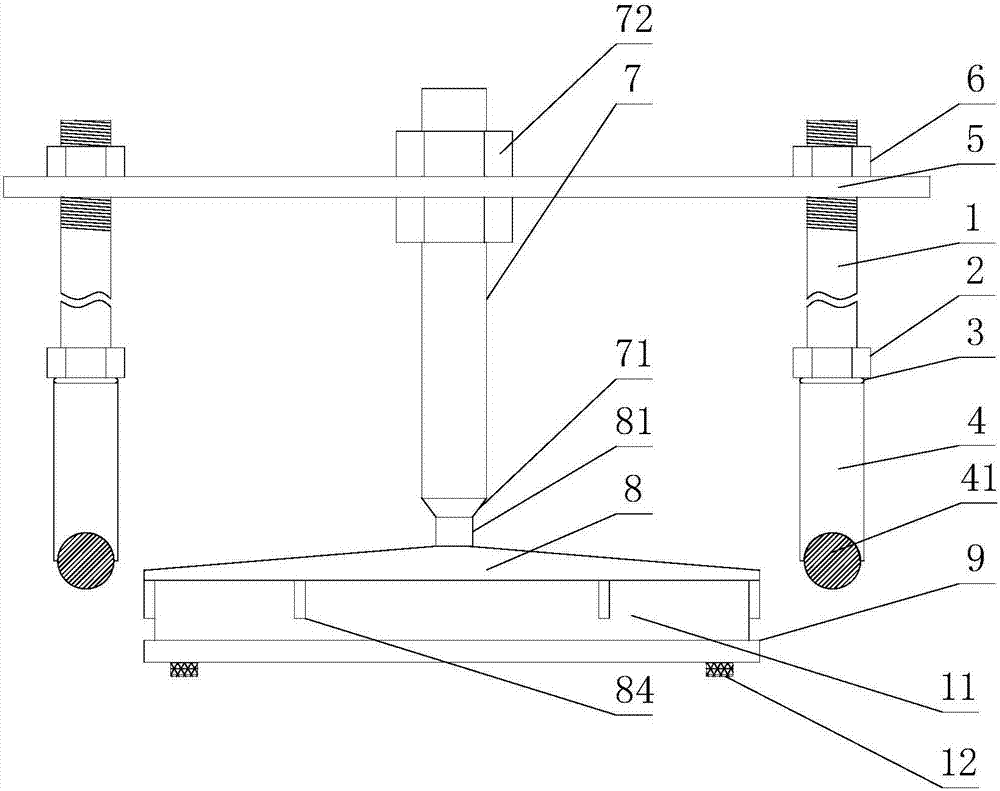

[0038] Such as Figure 1 to Figure 3 As shown, a honeycomb core assembly includes a honeycomb core body 11, a seal 12 for sealing between the bottom surface of the honeycomb core body 11 and the top surface of the formwork, and an anti-floating structure for providing anti-floating constraints for the honeycomb core body 11, It also includes a surrounding edge 9, which is used to be fixed on the formwork, and after the honeycomb core body 11 is placed on the installation position on the formwork, all sides around the honeycomb core body 11 are in contact with the inner side of the surrounding edge 9 .

[0039] Specifically, in the above honeycomb core components, the seal 12 is mostly a rectangular ring-shaped seal 12 that matches the shape of the bottom surface of the honeycomb core body 11, and the outer edge of the seal 12 is slightly smaller than or equal to the bottom surface of the seal 12 body. On the outer edge, before the honeycomb core body 11 is installed in place,...

Embodiment 2

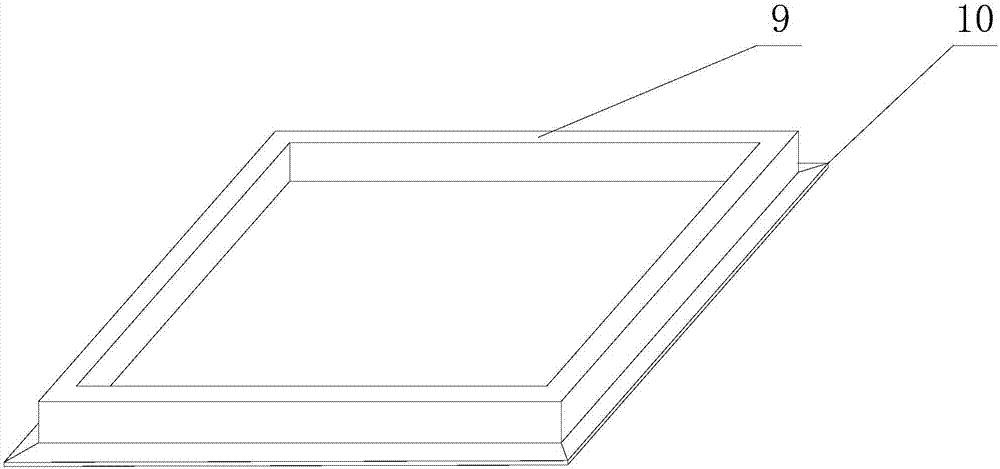

[0044] Such as Figure 1 to Figure 3 As shown, this embodiment is further limited on the basis of Embodiment 1: as mentioned above, the surrounding edge 9 can adopt a split type. Constraints are provided, so the perimeter 9 includes at least four panels. As an integrated design, to improve the installation efficiency and installation accuracy of the surrounding edge 9, the surrounding edge 9 is a frame-like structure surrounded by wooden boards;

[0045] There are lugs 10 on all sides of the frame-like structure. After the edge 9 is connected to the formwork, the bottom of the lugs 10 is in contact with the formwork, and the lugs 10 are located outside the frame-like structure.

[0046] As a person skilled in the art, because the formwork needs to be disassembled later, and the surrounding edge 9 will be solidified in the floor, the surrounding edge 9 and the formwork are preferably detachably connected, such as using iron nails, screws, tenon joints, etc. The mortise and te...

Embodiment 3

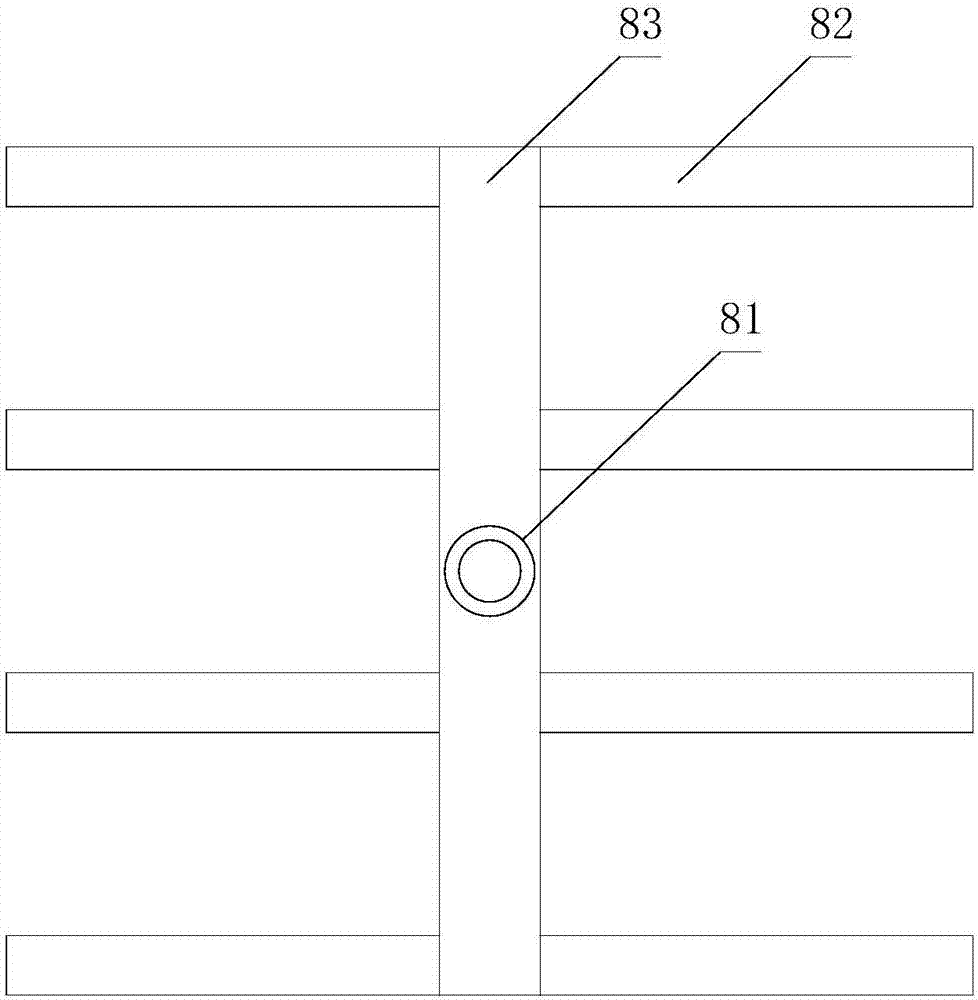

[0048] This embodiment is further limited on the basis of the technical solution provided in embodiment 1, as Figure 1 to Figure 3 As shown, as a specific implementation of the anti-floating structure, the anti-floating structure includes a frame body connected to the floor steel mesh, a pressure bar 7 connected to the frame body at the upper end, and a frame body for placing on the upper surface of the honeycomb core body 11. upper platen 8;

[0049] Described frame body comprises vertical rod and crossbeam 5, and described vertical rod comprises connecting seat 4 and column 1, and described connecting seat 4 is provided with internally threaded hole, and the lower end of column 1 is threadedly connected with internally threaded hole, and described crossbeam 5 The upper end of the column 1 is pierced through the through hole provided thereon;

[0050] It also includes a second nut 6 screwed to the upper end of the column 1 , the lower end surface of the second nut 6 is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com