Friction clutch with clutch disc for torque transmission

A friction clutch, torque transmission technology, applied in the direction of rotational vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., can solve problems such as loss of effect, increase in amplitude, increase the risk of disturbing vibration, etc., to avoid self-excitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

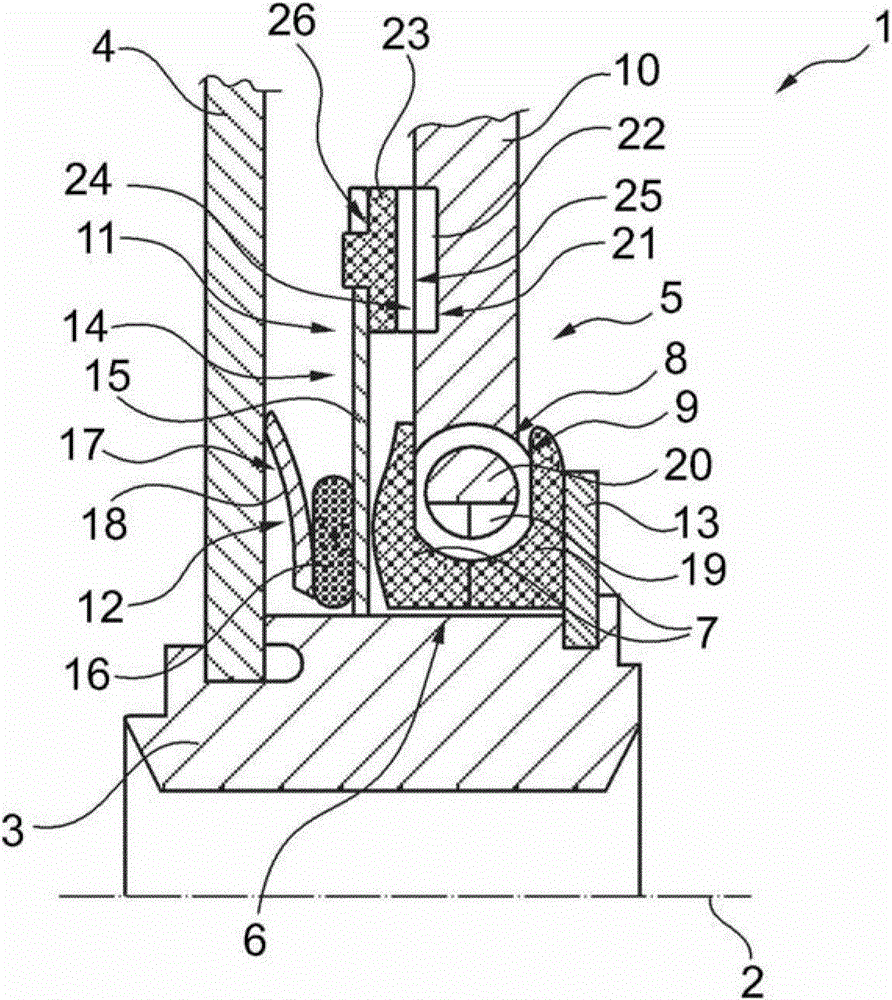

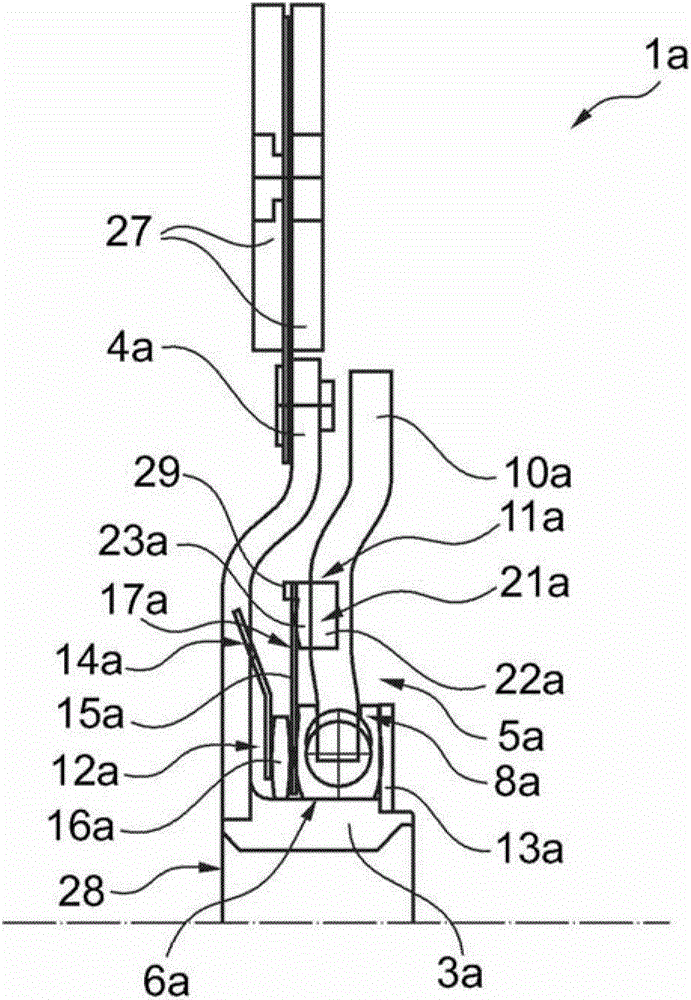

[0027] figure 1 A clutch plate 1 is shown which is accommodated in a non-illustrated friction clutch, which is arranged around an axis of rotation 2 and is connected with a hub 3 in a rotationally locking manner to the input shaft of the transmission. The disk part 4 is fixedly connected to the hub 3 , for example caulked as shown here, and accommodates a friction layer (not shown) for forming a friction engagement with the friction clutch.

[0028] Also arranged on the hub 3 is a rotational vibration damper 5 comprising a spring cage 6 formed by a cage part 7, a first energy accumulator 8 in the form of a coil spring 9 housed in the spring cage, a damping mass 10 and friction device 11. The torsional vibration damper 5 is rotatably accommodated on the hub 3 and is clamped axially on the disc part 4 with a cover plate 13 connected to the hub 3 , for example caulked as shown here, forming a slip clutch 12 between. To build up the prestressing force one cage part 7 bears aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com