Damping arrangement for dampening rotational irregularities in drive train of motor vehicle and method therefor

A technology for power trains and motor vehicles, applied in the direction of rotation vibration suppression, shock absorbers, mechanical equipment, etc., can solve the problems of insufficient decoupling or attenuation of rotation inhomogeneity, inflexible methods, and heavy requirements. Reliable determination of rotational inhomogeneity, increased flexibility and reduced rotational vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

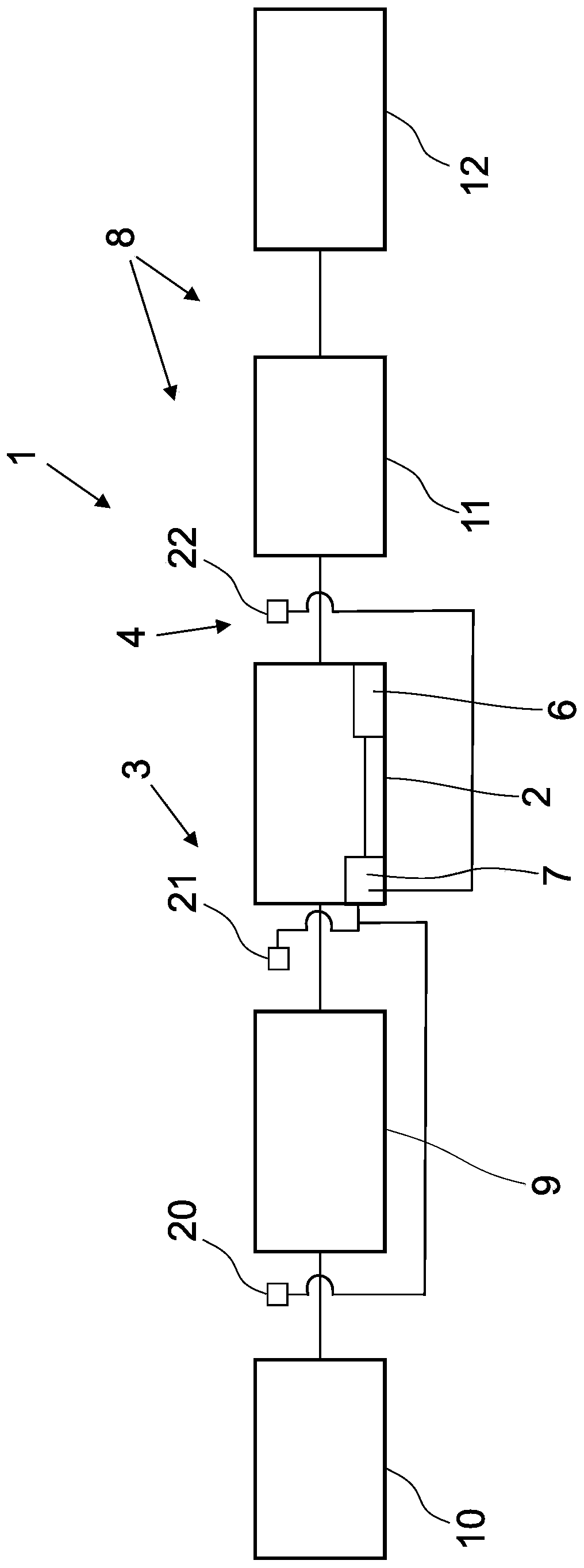

[0035] exist figure 1 A damping mechanism 1 for a drive train of a motor vehicle is shown in . In this case, the drive train includes an engine 10 which is connected torque-downstream to a rotational inhomogeneity pre-decoupler 9 . The rotational inhomogeneity pre-decoupler 9 is further connected torque downstream to a slip mechanism 2, wherein the slip mechanism 2 is connected on the output side to a transmission 11, and the transmission 11 is connected to further transmission elements (in figure 1 is referred to as the rest of the power train 12) connection. A crankshaft position sensor 20 is arranged between the engine 10 and the rotational irregularity pre-decoupler 9 . A rotational speed sensor 21 is arranged between the rotational unevenness pre-decoupler 9 and the slip mechanism 2 , and a further rotational speed sensor 22 is situated between the slip mechanism 2 and the transmission 11 . The rotational speed sensor 21 is therefore arranged in the input region 3 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com