Mine plant dust removal purifier for environmental protection equipment

A technology of environmental protection equipment and purifiers, applied in chemical instruments and methods, climate change adaptation, human health protection, etc., can solve problems such as increased load of induced draft fans, reduced effective filter area, dust condensation, etc., to avoid low temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

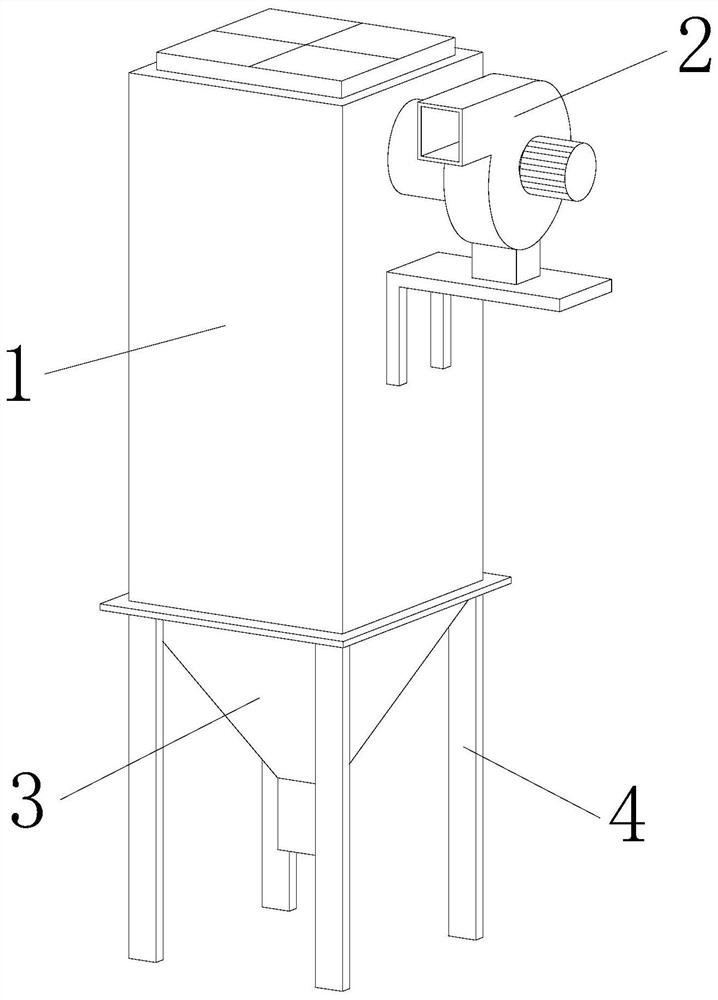

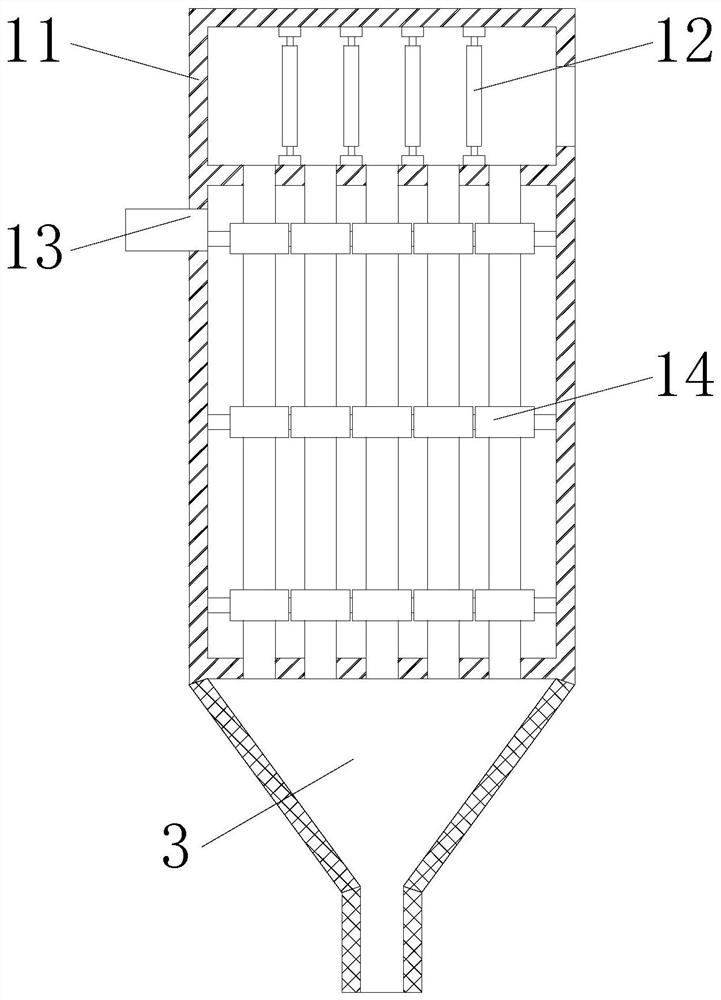

[0023] as attached figure 1 to attach Figure 4 Shown:

[0024] The present invention is a mine factory dedusting purifier for environmental protection equipment. Its structure includes a dedusting host 1, a fan 2, a dust outlet 3, and a support foot 4. The upper right end of the dedusting host 1 is embedded with a fan 2 and connected to each other. The dust outlet 3 is welded to the bottom of the dust removal main machine 1 and communicates with each other. The top of the support leg 4 is welded to the bottom of the dust removal main machine 1. The dust removal main machine 1 includes a box body 11, an antifreeze device 12, an air outlet pipe 13, and a filter bag. Device 14, the upper right end of the box body 11 is embedded with a fan 2 and communicates with each other, the antifreeze device 12 is arranged at the upper end inside the box body 11, and the air outlet pipe 13 is embedded and installed at the upper left end of the box body 11 and is connected to each other. Th...

Embodiment 2

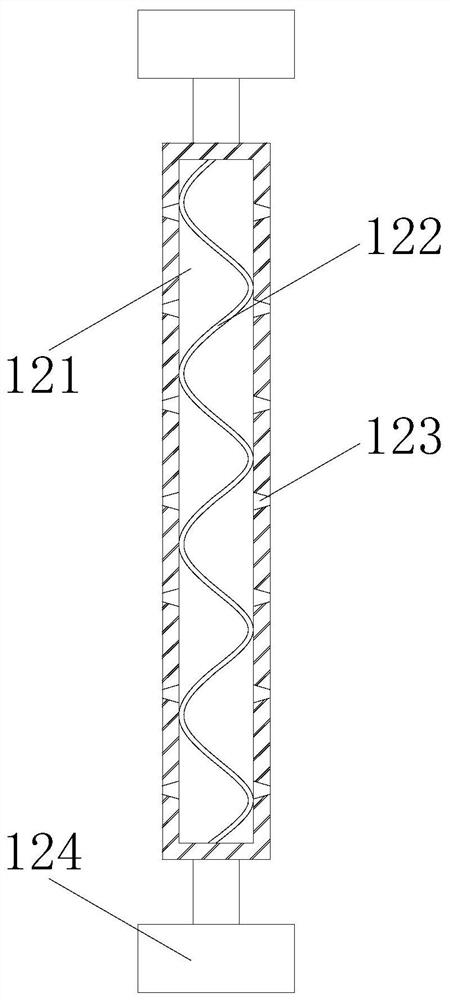

[0030] as attached Figure 5 to attach Figure 7 Shown:

[0031]Wherein, the filter bag device 14 includes a pulling device 141, a cleaning device 142, and a filter bag 143. One end of the pulling device 141 is arranged on the inner wall of the box body 11, and the other end of the pulling device 141 is fixedly connected to the outer end of the cleaning device 142. The filter bag 143 runs through the inside of the cleaning device 142, and there are twenty filter bags 143 in one group, which are evenly distributed inside the box body 11, and each filter bag 143 has three upper, middle and lower Each part is equipped with a cleaning device 142, which is beneficial to disperse and filter the exhaust gas and improve the overall filtering effect of the exhaust gas. dew.

[0032] Wherein, the pulling device 141 includes a fixed block 41a, a sliding block 41b, a tension spring 41c, and a linkage rod 41d, the right end of the fixed block 41a is fixedly installed on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com