Medium-temperature heat treatment method for floor wood

A technology of warm heat treatment and wood, which is applied in the direction of wood drying, lighting and heating equipment, heating to dry solid materials, etc., and can solve the problems such as the moisture content should not be too low, rib grain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

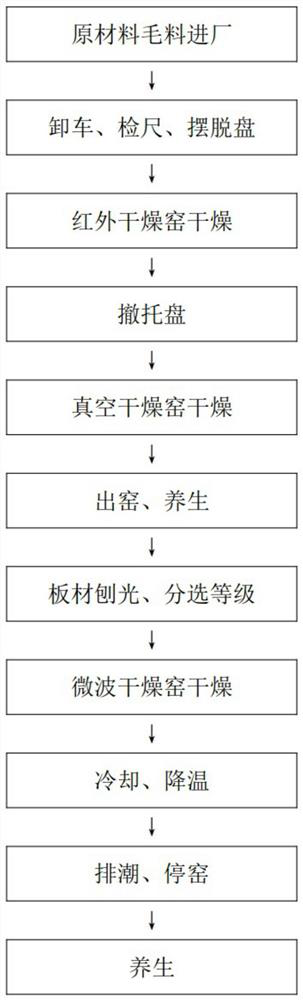

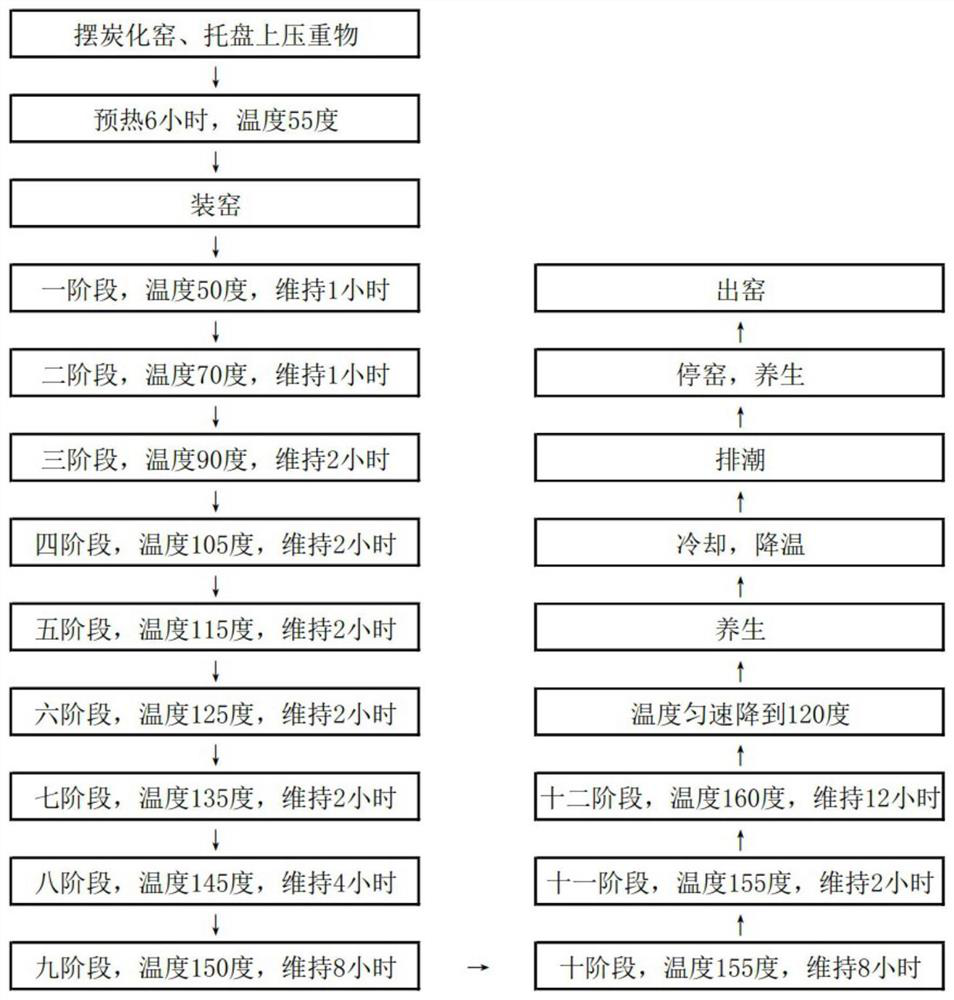

[0020] combine Figure 1 to Figure 3 , a method for moderate heat treatment of floor wood, comprising the following steps:

[0021] (1) Wood wool is placed on the pallet, dried in an infrared drying kiln for 10 days;

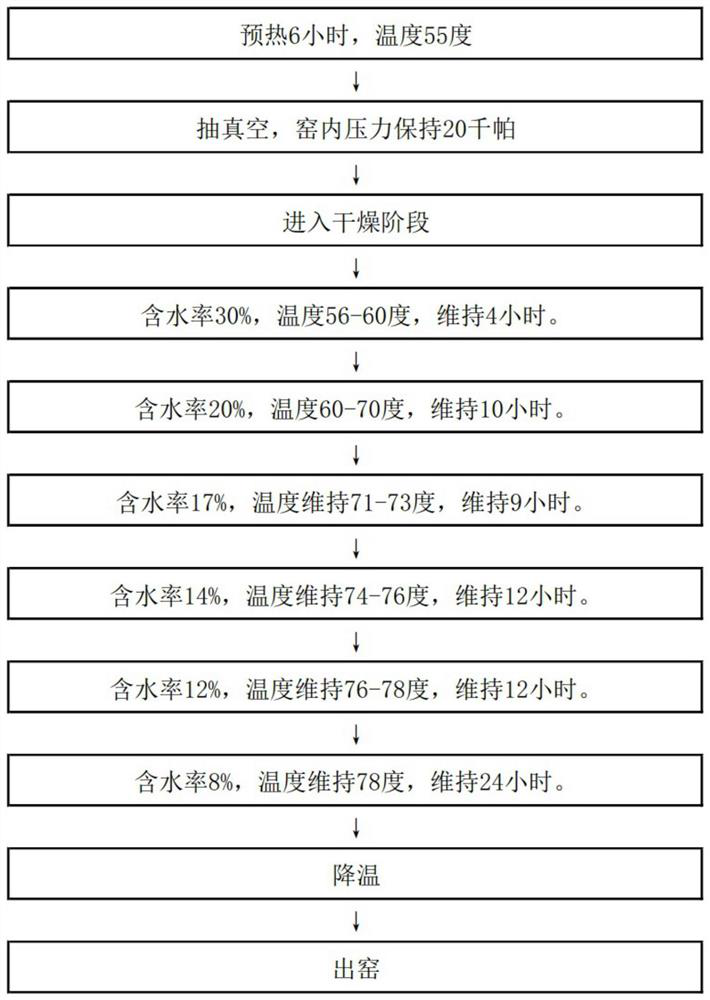

[0022] (2) Preheat the vacuum drying kiln at 55°C for 6 hours, evacuate, keep the pressure in the kiln at 20KPa, put the wood into the vacuum drying kiln; use the gradient heating method to dry, and after the moisture content of the wood reaches 30%, heat up to 58°C; when the wood moisture content reaches 20%, raise the temperature to 65°C; when the wood moisture content reaches 17%, the temperature rises to 72°C; when the wood moisture content reaches 14%, maintain the temperature at 75°C; After reaching 12%, the temperature is maintained at 77°C for 12 hours; finally, the temperature is maintained at 78°C for 24 hours;

[0023] (3) Gradient cooling is carried out at a rate of 2 °C / h. When the temperature is lowered to 40 °C, after leaving the kiln, it is kep...

Embodiment 2

[0027] The floor made of the medium-temperature heat-treated wood processed by the method in Example 1 and the ordinary wood without medium-temperature heat treatment is respectively in the environment where the relative air humidity is 0, 30%, 60% and 90%. After being treated for 120 hours at a temperature of 30°C, the change of moisture content in the wood was detected; the detection results are shown in Table 1.

[0028] Table 1 Variation of wood moisture content

[0029]

[0030] It can be seen from the above table that the water absorption rate of untreated wood is higher than that of wood treated at medium temperature, and it is easy to absorb moisture and roll up, and ribs appear.

Embodiment 3

[0032] The floor made of the middle-temperature heat-treated wood processed by the method in Example 1 and the common wood without the middle-temperature heat treatment is respectively in the environment where the relative air humidity is 0, 30%, 60% and 90%. After being treated at a temperature of 30° C. for 120 hours, the change of the floor width was detected, and the results are shown in Table 2.

[0033] Table 2 Floor Width Variations

[0034]

[0035] It can be seen from the above table that after the floor has been treated at medium temperature, when the air humidity is 60% (common humidity in summer), the change in width of the floor is very small by 1.55mm, and it will not cause the rib pattern problem of moisture absorption and moisture discharge .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com