Fibroin protein fiber scaffold and preparation method thereof

A fibrous scaffold and silk fibroin technology, applied in medical science, prostheses, etc., can solve the problems of complex processing, unfavorable cell and tissue growth, and limited tissue growth in electrospinning technology, and achieve easy batch processing and excellent Mechanical properties, the effect of reducing purification steps and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Natural mulberry silk was degummed by boiling 0.05wt% sodium carbonate solution for 30 minutes, and obtained silk fiber after repeating 3 times; the silk fiber was dispersed in 88% formic acid solvent, and the concentration of the obtained silk fiber dispersion was 2% ;

[0032] (2) Inject the silk fiber dispersion liquid into the mold for freezing treatment (temperature -20°C) to obtain silk fiber frozen body;

[0033] (3) immerse the frozen silk fiber body in step (2) in methanol to remove formic acid, and then soak and wash with deionized water to obtain a wet silk fibroin fiber scaffold;

[0034] (4) Freezing the wet silk fibroin fiber scaffold obtained in step (3) at -20°C, and then freeze-drying at -40°C to obtain a silk fibroin scaffold.

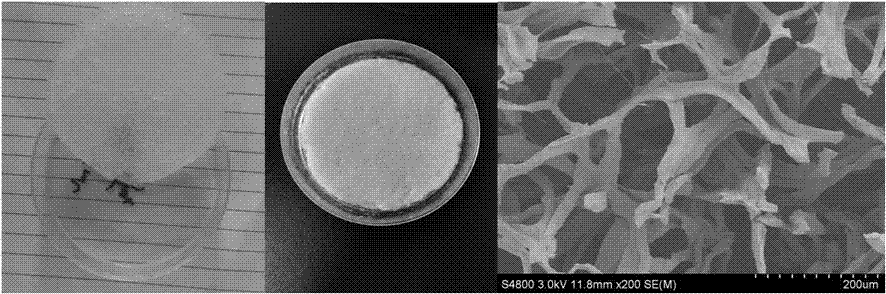

[0035] attached figure 1 It is the photos of the wet (left) and dry (middle) silk fibrous scaffolds obtained above and the scanning electron microscope picture (right). It can be seen from the figure that the interior of ...

Embodiment 2

[0037] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and the silk fiber was obtained after repeating 3 times; the silk fiber was dispersed in 98% formic acid solvent, and the concentration of the obtained silk fiber dispersion was 3% ;

[0038] (2) Inject the silk fiber dispersion liquid into the mold for freezing treatment (temperature -10°C) to obtain silk fiber frozen body;

[0039] (3) immerse the frozen silk fiber body in step (2) in ethanol to remove formic acid, and then soak and wash with deionized water to obtain a wet silk fibroin fiber scaffold;

[0040] (4) The wet silk fibroin fiber scaffold was frozen at -10°C, and then freeze-dried at -20°C to obtain the silk fibroin scaffold.

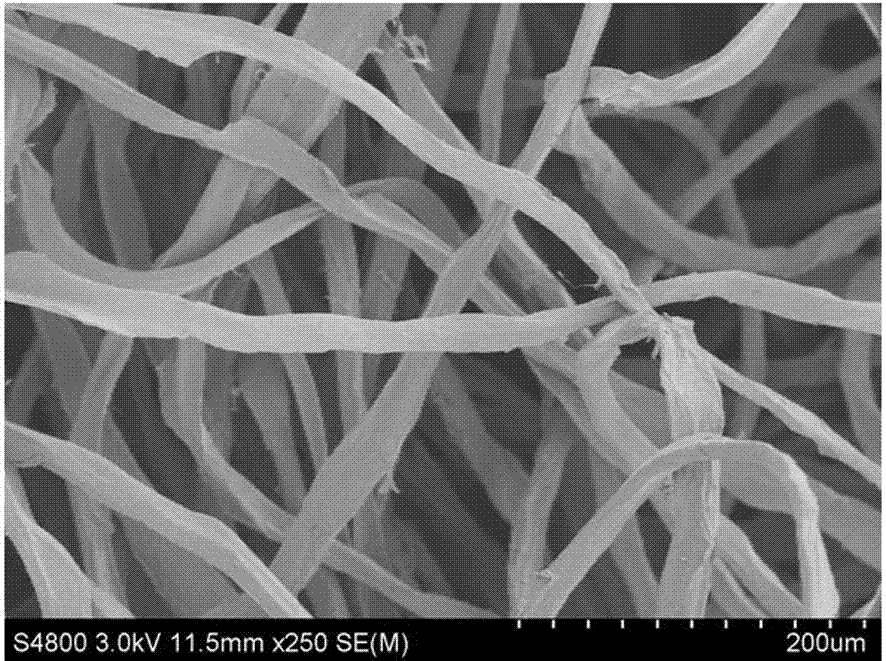

[0041] attached figure 2 The photo (left) and scanning electron microscope image (right) of the silk fiber scaffold obtained above; it can be seen from the figure that the interior of the scaffold is mainly composed of fibers, and s...

Embodiment 3

[0043] (1) Natural tussah silk was degummed by boiling 0.05wt% sodium carbonate solution for 30 minutes, and obtained silk fiber after repeating 3 times; the silk fiber was dispersed in 98% formic acid solvent, and the concentration of silk fiber dispersion obtained was 5% ;

[0044] (2) Inject the silk fiber dispersion liquid into the mold for freezing treatment (temperature -30°C) to obtain silk fiber frozen body;

[0045] (3) Immerse the frozen silk fiber body in step (2) in propanol to remove formic acid, then soak and wash with deionized water to obtain a wet silk fibroin fiber scaffold;

[0046] (4) The wet silk fibroin fiber scaffold was frozen at -20°C, and then freeze-dried at -80°C to obtain a natural silk fibroin scaffold.

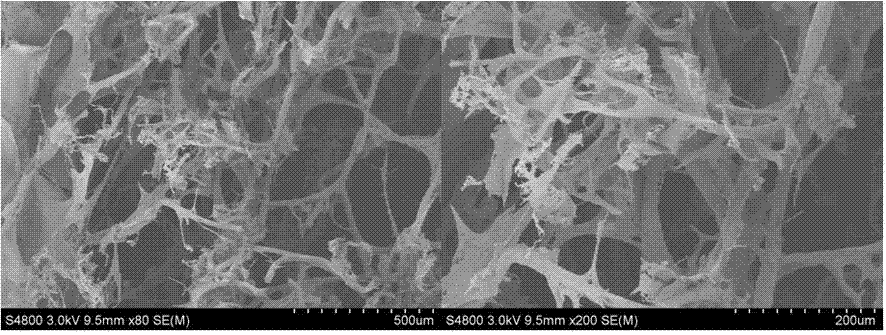

[0047] attached image 3 It is the scanning electron micrograph of the cross-section of the silk fibroin fiber support obtained above. It can be seen from the figure that the inside of the support is mainly composed of fibers, and the fibers hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com