Manufacturing method of 718plus special-shaped cartridge receiver forging

A manufacturing method and forging technology, which are applied in the field of 718plus special-shaped casing forgings, can solve the problems that the structure and properties are difficult to meet the use requirements, the forging temperature range is narrow, and the forgings streamline cutting, etc., so as to avoid cracking and coarse grains. , The effect of improving the forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

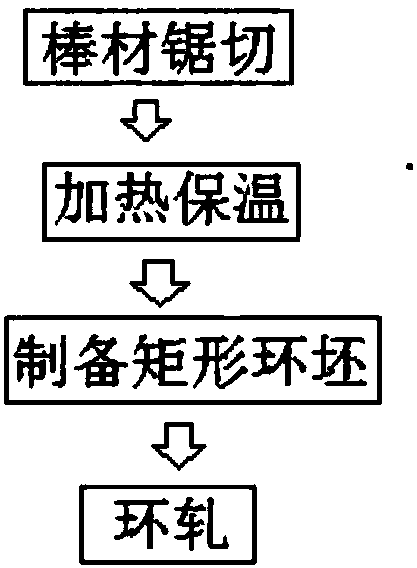

[0024] A method for manufacturing 718plus special-shaped casing forgings, such as figure 1 As shown, it includes the steps of sawing 718plus alloy bar, heating and heat preservation, preparation of rectangular ring billet, and rolling. In the heating and heat preservation step, the sawed 718plus alloy bar is heated to 1000-1100°C, and heat preservation is carried out. Proceed according to the following method, according to the effective thickness of the bar, keep warm for 6 minutes according to 10mm.

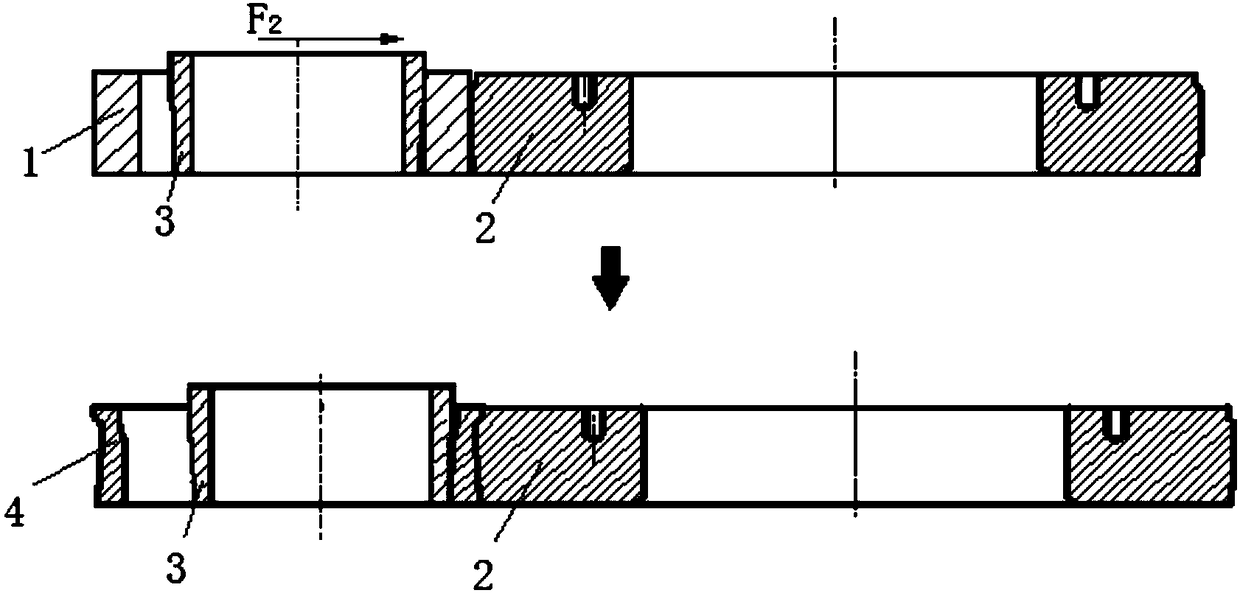

[0025] After the heat preservation is completed, it is subjected to upsetting, punching, horse frame expansion and pre-rolling into a rectangular ring billet 1. In some embodiments, before the above-mentioned heating of the rod, it is wrapped with ceramic fiber After that, it is heated to reduce the temperature drop when it is sent into the upsetting punching hole, which can ensure that the temperature during processing can meet the requirements and avoid cracks during processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com