Fully automatic high-frequency highland barley parching machine

A frying machine, fully automatic technology, applied in application, food processing, food science and other directions, can solve problems such as restricting the level of production technology, low production efficiency, destroying the ecological environment, etc., to improve frying efficiency and short preheating time. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

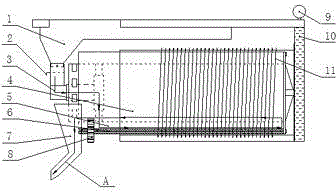

[0019] Such as figure 1 As shown, the present invention includes a feed hopper 1, a hopper 7, a return cylinder 4, a roasting cylinder 5 and a high-frequency coil 11, the return cylinder 4 is nested inside the roasting cylinder 5, and the discharge port of the discharge hopper 7 Located below the roasting tube 5, the feeding end of the feeding hopper 1 is connected to the feeding end of the roasting tube 5, and a discharge gate 2 and a barley for conveying highland barley are arranged between the feeding hopper 1 and the roasting tube 5. Rotating bearings, the discharge end of the head of the return cylinder 4 is connected to the feed end of the discharge hopper 7, river sand 6 is placed in the frying cylinder 5, and spiral blades are arranged in the frying cylinder 5 and the return cylinder 4 , the helical blade in the frying cylinder 5 is opposite to the helical blade in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com